3D printing technology, also known as additive manufacturing, is revolutionizing the modern manufacturing field. Of various 3D printing materials, metal powders have been attracting lots of attention due to their excellent mechanical properties and broad application prospects. Titanium alloy powder, in particular, holds an irreplaceable position in high-end fields such as aerospace, medical implants, and automotive manufacturing.

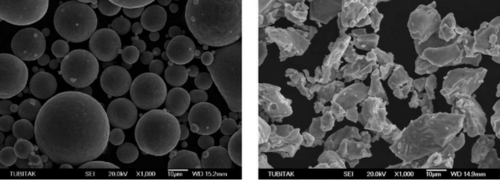

The preparation process of titanium alloy powder directly affects its printing performance. Currently, mainstream preparation methods include gas atomization (GA) and plasma rotating electrode process (PREP). These processes provide powders that are spheroidal and low porosity, which ensures high-quality parts in 3D printing technologies like selective laser melting (SLM) and electron beam melting (EBM). Among the titanium alloys, Ti-6Al-4V, also known as Grade 5 titanium alloy, is the most mature and most used 3D printing titanium material.

Spherical titanium alloy powder is an ideal raw material for metal 3D printing, offering several advantages:

Ti-6Al-4V is an α+β two-phase titanium alloy, where the numbers represent percentages of elements. α-phase is stabilised by aluminum, which enhances strength and heat resistance, and β-phase is stabilised by vanadium, which makes it workable. The typical two-phase structure gives the alloy outstanding overall properties.

Ti-6Al-4V possesses high strength-to-weight ratio, low weight, non-magneticity, high temperature resistance, greater corrosion resistance, and cold brittleness absence. It is also biocompatibility, which has rendered it a favourite to be implanted in patients. With the incorporation of 3D printing, intricate titanium implants are now very rampant in the treatment of patients.

To meet broader application needs, an upgraded version, Ti-6Al-4V ELI, was developed by strictly limiting oxygen (O), carbon (C), and nitrogen (N) content. This variant offers significantly improved plasticity and low-temperature toughness. The differences between the two are as follows:

2.3.1 Chemical Composition:

|

Component |

Ti |

Al |

V |

Fe |

O |

C |

N |

H |

Others |

|

Bal. |

5.5–6.5% |

3.5–4.5% |

≤0.25% |

≤0.20% |

≤0.08% |

≤0.05% |

≤0.0125% |

≤0.1% |

|

|

Bal. |

5.5–6.5% |

3.5–4.5% |

≤0.20% |

≤0.13% |

≤0.03% |

≤0.03% |

≤0.008% |

≤0.1% |

* Custom oxygen content with lower levels is available from SAM. Please feel free to contact us.

2.3.2 Mechanical Properties:

|

Property |

Ti-6Al-4V (Standard) |

Ti-6Al-4V ELI |

|

Tensile Strength (MPa) |

≥895 |

≥825 |

|

Yield Strength (MPa) |

≥825 |

≥760 |

|

Elongation (%) |

≥10 |

≥15 |

|

Reduction of Area (%) |

≥25 |

≥30 |

|

Fracture Toughness (MPa√m) |

55–60 |

65–70 |

|

Fatigue Limit (10⁷ cycles, MPa) |

500–550 |

450–500 |

|

Hardness (HV) |

330–360 |

310–340 |

|

Impact Toughness (J/cm²) |

25–35 |

35–45 |

2.3.3 Physical Properties:

|

Property |

Ti-6Al-4V (Standard) |

Ti-6Al-4V ELI |

|

Density (g/cm³) |

4.43 |

4.42 |

|

Melting Range (°C) |

1604–1660 |

1604–1660 |

|

Thermal Conductivity (W/m·K) |

7.2 |

7.1 |

|

Specific Heat Capacity (J/kg·K) |

560 |

565 |

|

Thermal Expansion Coefficient (10⁻⁶/K) |

8.6 (20–100°C) |

8.7 (20–100°C) |

|

Electrical Resistivity (μΩ·m) |

1.7 |

1.72 |

|

Magnetic Permeability |

1.00005 |

1.00005 |

|

Elastic Modulus (GPa) |

110–114 |

108–112 |

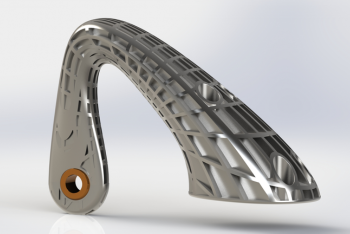

Spherical Ti-6Al-4V is a material of choice for lightweight, high-strength, and biocompatible uses. Through additive manufacturing, it is making revolutionary impacts on a number of high-end markets.

Weight reduction in aerospace is very economically valuable. Boeing research reveals that a weight reduction of 1 kg per aircraft saves around $1,000 annually in fuel costs. Airbus' A350XWB uses EBM-printed titanium wing fittings, amalgamating 12 traditional components into a single one. GE Aviation's LEAP fuel nozzle, printed using SLM, amalgamates 20 components and conserves 25% of the weight.

Because of its biocompatibility, Ti-6Al-4V is used extensively in orthopedic implants. Gradient-porosity hip cups (30–70% porosity) were designed by the German company EOS to maximize mechanical performance in addition to bone integration. Stryker patient-specific cranial plates reduce surgery time by 40%, and spinal fusion cages increase bone fusion rates by 20%.

In high-end cars, Ti-6Al-4V is gaining traction. Ferrari’s F1 team uses 3D-printed titanium piston rods, 45% lighter than steel. BMW i8’s door hinges feature lightweight lattice structures, and Tesla employs the alloy in battery cooling systems, offering 5× better corrosion resistance than aluminum.

Bicycles are one of the largest application areas, from frames to helmets. Team GB's 2024 Paris Olympic bikes feature 3D-printed titanium parts. Maker Empire Cycles claimed the new frames are 33% lighter without sacrificing strength.

|

Alloy Powder |

Composition |

Key Advantages |

Major Drawbacks |

Typical Applications |

|

99.5% Ti |

30–40% lower cost; high plasticity (25% elongation); best corrosion resistance |

Low strength (240–550 MPa); poor high-temp performance |

Chemical pipes; desalination; low-stress implants |

|

|

Ti6242 |

Excellent high-temp performance (450°C long-term); 50% higher creep resistance |

30% higher cost; difficult to process |

Jet engine blades; high-temp structures |

|

|

Ti5-2.5 |

Superior low-temp toughness (-250°C); good weldability |

Low room-temp strength |

Liquid hydrogen/oxygen tanks; spacecraft parts |

|

|

Ti-3Al-2.5V |

Excellent cold-forming; moderate strength |

Slightly lower corrosion resistance |

Aircraft hydraulic tubes; sports gear |

|

|

γ-TiAl |

Ti-48Al-2Cr-2Nb |

Ultralight (3.9 g/cm³); high strength at 700°C |

Brittle at room temp; narrow processing window |

Jet engine turbine blades |

While Ti-6Al-4V is versatile, other titanium alloys may excel in specific scenarios. Below is a detailed comparison of five alternatives:

Spherical Ti-6Al-4V titanium alloy powder, with its perfect balance of properties, has become the undisputed "star material" in metal 3D printing. From aerospace components to life-saving implants, from race cars to mountaineering gear, Ti-6Al-4V continues to demonstrate its unique value across high-end industries. As 3D printing technology advances, its applications will only grow broader.

United States

.png)