The rapid development of the information and optoelectronics fields has placed extremely high demands on the surface flatness and cleanliness of materials. Chemical Mechanical Polishing (CMP) is currently one of the primary technologies for achieving ultra-precision surface processing. Common polishing powders include cerium oxide, magnesium oxide, silicon oxide, and silicon carbide. Among these, cerium oxide (CeO₂) is an important rare earth oxide. Its polishing powder offers advantages such as strong cutting ability, high polishing efficiency, high precision, excellent polishing quality, a clean operating environment, low pollution, and a long service life.

|

|

Chemical Formula: CeO₂ Product Name: Cerium Oxide Powder Brand: Stanford Advanced Materials Characteristics: Insoluble in water and alkali, slightly soluble in acid. Cerium oxide is toxic, odorless, non-irritating, safe, reliable, and stable in performance. Uses: Currently, cerium oxide polishing is mostly applied in glass polishing. |

* Please contact us for detailed specifications. We can adjust according to customer needs.

Wide-ranging polishing applications include:

Cerium oxide (CeO₂) polishing works through both chemical and mechanical actions. The particles grind the surface while also reacting with it chemically. Together, these effects remove material smoothly and precisely. Let's examine how this process works in detail.

1. Chemical Action

Cerium oxide possesses unique Ce⁴⁺/Ce³⁺ redox properties. In an aqueous environment, its surface can undergo chemical reactions with many materials, particularly those with oxide surfaces (e.g., SiO₂, glass, sapphire, tantalum, etc.).

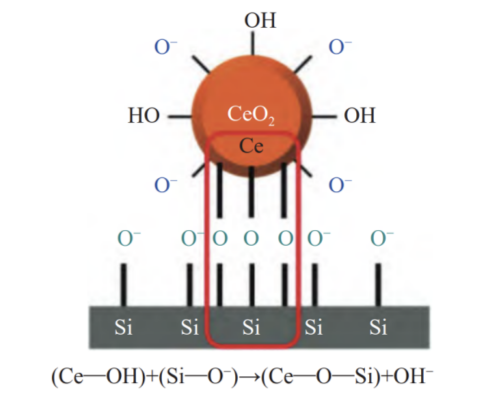

Taking the interaction mechanism between CeO₂ and SiO₂ as an example:

Fig 1. Schematic diagram of Ce-O-Si bonding mechanism during CMP

At a suitable pH (e.g., weakly acidic or neutral), CeO₂ may establish hydrogen bonds or covalent bridging with hydroxyl groups at SiO₂ surfaces such that CeO₂ active sites may exhibit preference for Si atoms. Such chemical adsorption forms a weakly bonded middle silicon oxide layer (e.g., [Ce–O–Si] bonds) on the surface of the polished material.

This intermediate layer is more prone to fragmentation than the native SiO₂ and hence is mechanically removable by abrasive particles.

2. Mechanical Action

As a hard nanoparticle, cerium oxide typically has a certain hardness (Mohs hardness ~6–7). Under pressure and motion, it applies localized shear or friction forces to the material surface, achieving micro/nano-scale physical abrasion and removal.

3. Synergistic Mechanism

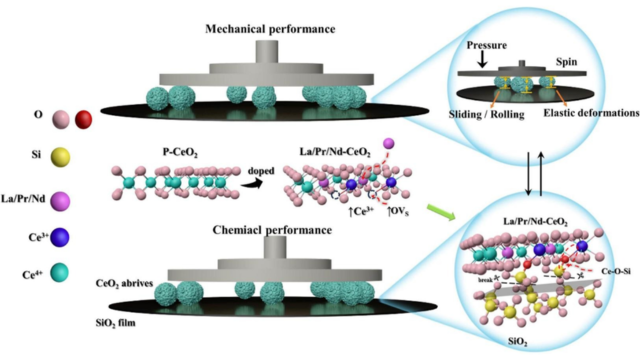

As shown in Figure 2, cerium oxide CMP polishing can be viewed as a three-step synergistic process:

Fig 2. Collaboration Mechanism[1]

Being a key material in CMP, the polishing performance of cerium oxide is influenced by many factors.

1. Particle Size

The influence of the size of abrasive particles on the performance of CMP is complex, with mechanical grinding and chemical reaction mechanisms. The influencing factors are contact area, scratch depth, contact frequency, momentum, and chemical activity. Experiments show that 100 nm CeO₂ abrasives achieve the highest material removal rate (MRR). While 10 nm particles, due to their high chemical activity and large specific surface area, also exhibit a high MRR. Bigger particles at higher loads tend to induce deeper scratches and higher friction and enhance MRR. Some studies report that smaller particles also lead to maximum MRR, and therefore particle size effect on polishing performance is nonlinear but requires further theoretical modeling and experimental evidence.

2. Morphology and Structure

The morphology and structure of cerium oxide abrasives also significantly affect the CMP performance. Studies found that flake-like structured CeO₂ abrasives, though exhibiting the maximum MRR, tend to cause scratches because of their sharp corners. Almost spherical abrasives, meanwhile, maintain high MRR, significantly reduce the roughness of the surface with the highest polishing quality. Spherical abrasives participate in polishing by rolling rather than sliding, with low friction and reduced damage.

3. Ce³⁺ Concentration

Ce³⁺ content is also one of the key parameters that affect the chemical activity and the ability to polish with nano-CeO₂ abrasives. As active sites on the surface, Ce³⁺ ions directly affect the efficiency of chemical reactions during polishing. Ion doping techniques, such as introducing Zr⁴⁺ or Gd³⁺ ions, can effectively modulate the crystal structure and promote Ce³⁺ generation.[2] Heat treatment parameters, particularly calcination temperature (within 600–1000°C) and reducing atmosphere control, are also effective methods for adjusting Ce³⁺ concentration.

In brief, cerium oxide abrasive polishing performance is influenced by several factors including particle size, morphology, and Ce³⁺ concentration. Optimization of structure and control of activity are the primary directions for enhancing CMP performance. Additional process optimization with increasing material fineness will further enhance efficiency, reduce damage, and expand applicability, driving cerium oxide polishing towards higher performance, lower defectivity, and broader application potential.

[1] Zhenyu Zhang, Ning Wang, Xingzi Wang, Zheng Zhao, Enhanced chemical mechanical polishing (CMP) performance of porous self-assembled spherical cerium oxide via RE(La/Pr/Nd) doping, Applied Surface Science, Volume 679, 2025,161236, ISSN 0169-4332, https://doi.org/10.1016/j.apsusc.2024.161236.

[2] Ning Xu, Yuxin Luo, Yu Lin, Jiahui Ma, Yongping Pu, The influence of CeO2 abrasive size on the performance of photocatalytic assisted chemical-mechanical polishing by Y/Pr co-doping strategy, Colloids and Surfaces A: Physicochemical and Engineering Aspects, Volume 684, 2024, 133107, ISSN 0927-7757, https://doi.org/10.1016/j.colsurfa.2023.133107.

United States

.png)