Spherical stainless steel powder has round, uniform particles. It flows well and packs tightly. This powder works perfectly for 3D printing and metal molding. Popular types include 316L for medical implants and 304L for food processing equipment and chemical containers.

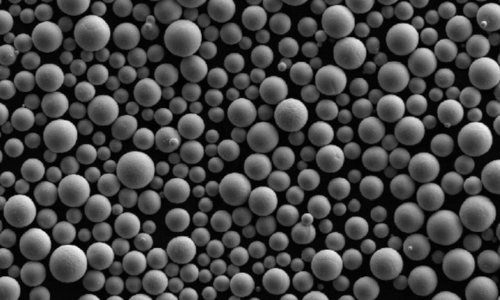

Spherical stainless steel powder is an ultra-performance metal powder in the form of spherical stainless steel alloy particles (e.g., 316L, 304, 17-4PH). The powders are prepared by high-technology atomization processes such as gas atomization (GA) or plasma atomization (PA) to have excellent flowability, high bulk density, and a tight particle size distribution.

Since they have superior metallurgical properties, spherical stainless steel powders find widespread applications in additive manufacturing (3D printing), metal injection molding (MIM), and thermal spray coatings.

Compared to irregularly shaped powders, spherical stainless steel powders offer several critical benefits:

|

Grade |

Composition |

Key Properties |

Main Applications |

|

Fe-17Cr-12Ni-2.5Mo |

High corrosion resistance, biocompatibility |

Medical implants, marine components |

|

|

Fe-18Cr-8Ni |

Good weldability, cost-effective |

Food processing equipment, chemical containers |

|

|

17-4PH |

Fe-15Cr-4Ni-4Cu |

Precipitation hardening, high strength |

Aerospace, automotive parts |

|

Fe-13Cr |

High hardness, wear resistance |

Cutting tools, surgical instruments |

1. What stainless steel powder do I choose for highly corrosion-resistant applications?

We recommend 316L powder with 2-3% molybdenum content, with excellent resistance to chlorides and acidic environments. It is ideal for medical implants, marine hardware, and chemical processing plant equipment.

2. I am on a tight budget—what are some low-cost stainless steel powder options?

304L powder is a cost-effective alternative, exhibiting fair corrosion resistance and formability at a lower price than 316L. It can be applied to general industrial components, decorations, and consumer items.

3. What type of stainless steel powder is best suited for food processing applications?

Type 304L or 316L food-grade ss powders are the best options. They meet FDA food-contact standards and exhibit high corrosion resistance and cleanliness and are thus ideally suited for use in food processing equipment, containers, and machinery.

4. What is the best stainless steel powder for wear-resistant components?

420 powder has a higher carbon content (0.15-0.40%) and can be heat-treated to form excellent wear resistance, thus it is applicable to cutting tools, bearings, and other wear-resistant parts.

5. Which stainless steel powder is best for printing decorative pieces that are pleasing to the eye?

316L powder can be polished to an exquisite metallic appearance and is fingerprint and tarnish resistant, thus best for jewelry, luxury decor, and artwork.

6. Which stainless steel powder performs best under high-temperature conditions?

310S powder is suitable. Because it contains a higher chromium and nickel content (25Cr-20Ni). At high temperatures, it exhibits excellent oxidation resistance.