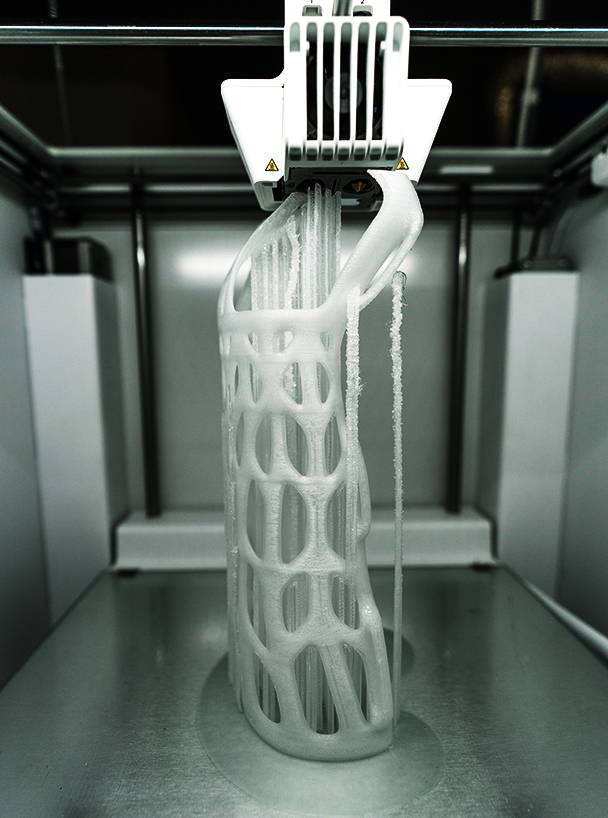

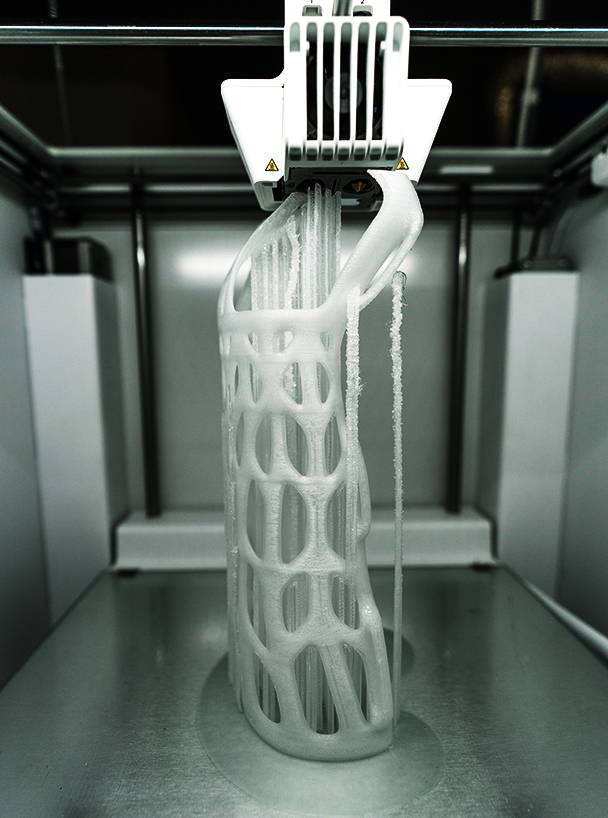

Metal powders are typically used as the raw material for creating metal parts in additive manufacturing. The powder particles are designed to have uniform size and shape characteristics, which ensure consistency and efficiency in the printing process.

Metal powders used in additive manufacturing are available in a variety of materials,

Metal powders can be used in the production of lightweight components. The resulting component has a high strength-to-weight ratio and can be used in the aerospace, automotive, and medical industries.

Metal powders used in lightweight components are available in a variety of materials,

Metal powders are used in Energy Storage Systems (ESS) as electrodes in batteries, supercapacitors for better energy storage capacity and power, hydrogen storage as metal hydrides, and thermal energy storage by heating the powder.

Metal powders used in energy storage systems are available in a variety of materials,

Iron: used in iron-based flow batteries, which are a promising alternative to traditional lithium-ion batteries for certain energy storage applications due to their low cost and potential for high energy density.

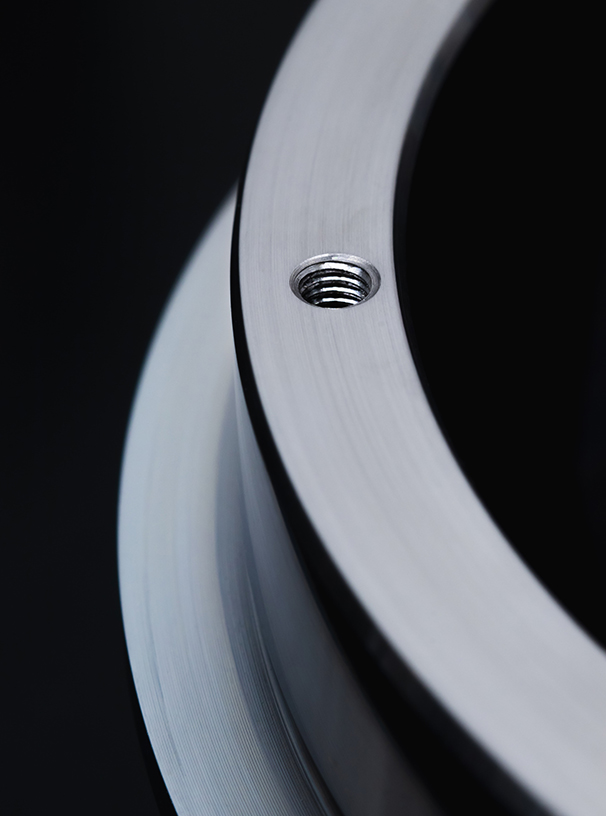

Metal powders are mixed with a binder material to form a feedstock for Metal Injection Molding (MIM). Powders are often in spherical shapes to ensure good flowability, and they can be customized with specific compositions and sizes to achieve desired properties.

Commonly used metal powders in metal injection molds are various,

Metal powders are commonly used in the manufacturing of refractory materials due to their excellent heat-resistant properties. They offer advantages over traditional refractory materials such as higher resistance to heat, durability, and design flexibility.

Metal powders in the production of refractory materials are available in a variety of materials,

Metal powders are commonly used in thermal spray coating processes to form a protective or decorative coating on the surface of a substrate. The coating offers desirable properties such as corrosion resistance, wear resistance, thermal insulation, and more.

Metal powders used in thermal spray coating are available in a variety of materials,

Metal powders are used in the manufacturing process of magnetic alloys, which are then sintered to create a crystalline structure that exhibits magnetic properties. The resulting magnetic alloy can be further processed to create magnets, sensors, and data storage devices. Examples of magnetic alloys include neodymium-iron-boron (NdFeB) and samarium-cobalt (SmCo), which are used to create powerful magnets.

Here are the most commonly used metal powders in magnetic alloys,

Metal powders are used in industrial tooling applications such as cutting tools, drill bits, and high-speed steel. They are mixed with other materials to create hard, wear-resistant coatings that enhance the durability and performance of these tools.

The most representative metal powders used in industrial tooling are here,

Metal powders are used in semiconductors as essential components in the production of thin films and coatings. They are often used to deposit metal layers onto a substrate. They are also used in the manufacture of various semiconductor packaging materials.

Some of the most widely used metal powders in semiconductor applications are here,

Metal powders are widely used in catalysts to facilitate chemical reactions and increase reaction rates. They are often used as active ingredients in catalyst formulations or as support materials for other catalytic elements.

Metal powders used in catalysts are available in a variety of materials,

Metal powders are an essential component in solid oxide fuel cells (SOFCs) and solid oxide electrolysis cells (SOECs). They are used as electrode materials due to their high electrical conductivity and stability at high temperatures.

The most representative metal powders used in SOFC and SOEC applications are here,

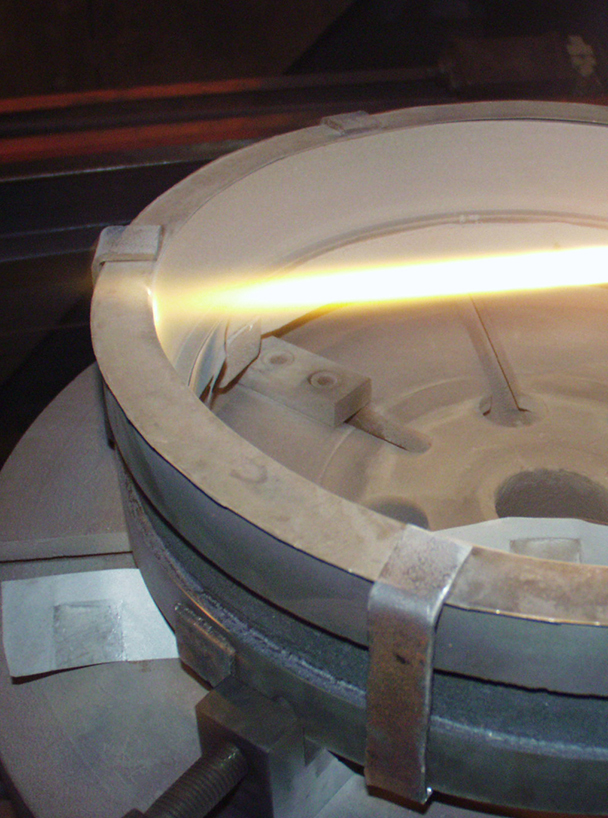

Metal powders are used as the starting material to produce high-quality, fully dense metal parts in Hot Isostatic Pressing (HIP). The process involves subjecting the powdered metal components to high temperature and pressure within a sealed container filled with gas.

Metal powders used in hot isostatic pressing are available in a variety of materials,