HEAs consist of 5 or more elements mixed in near-equal proportions, resulting in superior mechanical properties, excellent thermal stability, and wear and corrosion resistance. These characteristics make HEA powder ideal for advanced applications in the aerospace, automotive, and energy sectors.

High Entropy Alloy Powder is a blend of multiple metallic elements that are carefully selected to create a unique material with exceptional properties. Unlike conventional alloys that typically consist of one or two primary elements, high entropy alloys incorporate three or more elements in equal or near-equal proportions. This equal distribution of elements results in a highly stable and homogeneous microstructure, leading to outstanding mechanical, thermal, and chemical properties.

Traditional alloy powder and high-entropy alloy powder

.png)

Gas atomization is a common industrial method for producing high-entropy alloy powder. This process involves melting metal and using high-pressure gas to atomize it into fine droplets. These droplets rapidly cool in the air, forming powder. This technique can produce spherical, uniform powder with excellent flowability and filling properties. Gas-atomized powder typically has high purity and density, effectively reducing oxidation and impurities. Stanford Advanced Materials (SAM) provides top-quality atomized high-entropy alloy powder.

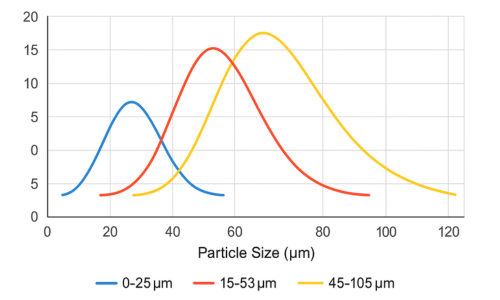

Particle Size Description

Superior Strength and Hardness: High Entropy Alloy Powder offers remarkable strength and hardness, making it ideal for applications where durability and resistance to deformation are crucial. Whether it's in aerospace components, automotive parts, or tooling, this powder provides the necessary strength to withstand demanding conditions.

Excellent Corrosion Resistance: High Entropy Alloy Powder exhibits exceptional resistance to corrosion, even in aggressive environments. This makes it an excellent choice for marine applications, chemical processing equipment, and oil and gas infrastructure, where protection against corrosion is essential for long-term reliability.

Enhanced Thermal Stability: High Entropy Alloy Powder demonstrates outstanding thermal stability, enabling it to withstand high temperatures without compromising its structural integrity. This characteristic makes it suitable for use in jet engines, gas turbines, and other heat-intensive environments, where traditional alloys may fail.

Versatility in Design: High Entropy Alloy Powder offers remarkable versatility in material design and composition. By carefully selecting different elemental combinations and proportions, engineers and researchers can tailor the material's properties to meet specific application requirements. This flexibility enables the creation of unique, customized solutions for a wide range of industries.

Ease of Processing: High Entropy Alloy Powder can be processed using various techniques, including powder metallurgy, additive manufacturing, and traditional casting methods. This ease of processing allows for efficient production and ensures compatibility with existing manufacturing processes, minimizing the need for significant equipment modifications.

The exceptional properties of High Entropy Alloy Powder make it a highly sought-after material across numerous industries. Some of the key applications include:

Aerospace and Aviation: High Entropy Alloy Powder is used in aircraft components, turbine blades, and rocket engines due to its high strength, corrosion resistance, and thermal stability.

Automotive: The powder finds applications in automotive parts, such as engine components, exhaust systems, and suspension parts, where strength, wear resistance, and corrosion resistance are critical.

Energy and Power: High Entropy Alloy Powder is utilized in power generation systems, including gas turbines and wind turbines, due to its excellent high-temperature performance and corrosion resistance.

Chemical Processing: The powder is employed in equipment used in chemical processing industries, where resistance to harsh chemicals and high temperatures is essential for prolonged operational life.

Medical and Biotechnology: High Entropy Alloy Powder is being explored for use in medical implants, dental prosthetics, and surgical instruments due to its biocompatibility and strength.

High Entropy Alloy Powder represents the future of advanced materials, offering a perfect blend of strength, durability, corrosion resistance, and thermal stability. Whether you're in aerospace, automotive, energy, or any other industry seeking to push the boundaries of what's possible, this remarkable powder empowers you to unlock new opportunities for innovation and efficiency.

Embrace the revolution in materials science and choose High Entropy Alloy Powder for your next breakthrough project. Contact us today to learn more and explore the limitless potential of this cutting-edge material.

2.5kg, 5kg, 25kg or as required;

Plastic bottle/can, iron can