Stanford Advanced Materials (SAM) offers high-quality spherical metal powders, including stainless steel and nickel alloys. These powders are designed for diverse Powder Metallurgy (PM) applications like Additive Manufacturing (AM), Hot Isostatic Pressing (HIP), and Metal Injection Molding (MIM), ensuring precision and performance in industrial manufacturing.

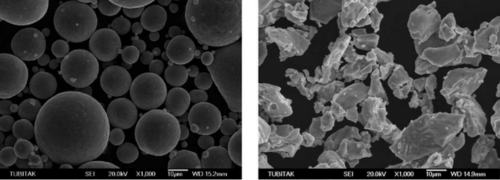

Spherical Powders are precisely manufactured through advanced processes, resulting in uniformly shaped particles. Unlike irregularly shaped powders, our spherical particles offer a wide range of advantages:

Improved Flowability: The uniform shape and size of the particles facilitate smoother flow through processing equipment, reducing blockages and improving efficiency.

Higher Packing Density: Spherical powders enable a higher packing density, leading to enhanced material properties and better mechanical performance.

Consistent Particle Size Distribution: Our Spherical Powders boast a consistent particle size distribution, ensuring uniformity in your end products and reducing variations.

Reduced Porosity: The tightly packed spherical particles contribute to reduced porosity in finished products, leading to improved strength and durability.

Enhanced Surface Finish: Spherical Powders can deliver exceptional surface finishes, making them ideal for applications where aesthetics matter.

Our Spherical Powders find applications across a wide spectrum of industries:

Additive Manufacturing (3D Printing): Achieve exceptional print quality, reduced powder recycling, and improved packing efficiency, resulting in precise and reliable parts.

Metal Injection Molding (MIM): Enhance the flowability of metal powders during the injection molding process, leading to complex and high-density components.

Cold Spray Technology: Utilize our powders for cold spray applications to create coatings or repair surfaces with minimal heat input.

Surface Coatings: Spherical Powders are ideal for thermal spray coatings, providing improved adhesion and uniformity on various substrates.

Chemical Applications: Benefit from the consistent particle size distribution and controlled flow characteristics in catalysts and other chemical processes.

At Stanford Advanced Materials, quality is paramount. Our Spherical Powders are manufactured under strict supervision and adhere to international standards. We employ cutting-edge production techniques to ensure a defect-free product with exceptional properties, giving you peace of mind in every application.

Our wide range of spherical metal powders includes:

Our specialty spherical products:

We understand that each project is unique. Therefore, we offer customized solutions to cater to your specific needs. From adjusting particle size to altering chemical compositions, our team of experts is ready to assist you in achieving your desired outcomes.

We prioritize sustainability and environmental responsibility. Our Spherical Powders are manufactured with processes that minimize waste generation and energy consumption, contributing to a greener future.