Stanford Advanced Materials (SAM) offers high-quality spherical tantalum powder known for its high melting point, excellent corrosion resistance, and biocompatibility. Ideal for aerospace, medical implants, 3D printing, and electronics, SAM's tantalum powder ensures superior performance and precision in various advanced applications.

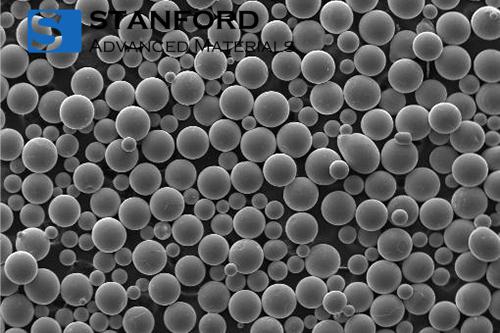

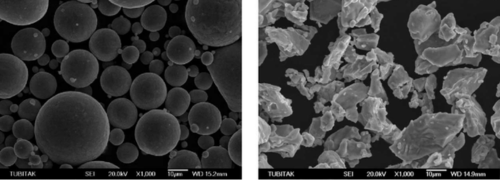

Spherical tantalum powder is generally fabricated by processes such as gas atomization, plasma rotating electrode process, or centrifugal atomization that gives rise to a consistently spherical shape with a particle size distribution accordingly.

|

Property |

Spherical Tantalum Powder |

Irregular Tantalum Powder |

|

Flowability |

Excellent (suitable for 3D printing) |

Poor |

|

Surface Area |

Lower |

Higher (suitable for capacitors) |

|

Cost |

Higher |

Lower |

|

Applications |

Additive manufacturing, coatings |

Traditional pressing & sintering |

Ta (50nm)

|

Ta (%) |

Ti (%) |

W (%) |

Mo (%) |

Cr (%) |

Fe (%) |

O (%) |

|

>99.9 |

<0.001 |

<0.001 |

<0.001 |

<0.0001 |

<0.01 |

<0.8 |

|

Powder Morphology |

Particle Size Distribution (nm) |

Specific Surface Area (m2/g) |

||||

|

D10 |

D50 |

D90 |

||||

|

Spherical |

0-30 |

50-60 |

<300 |

≥10.0 |

||

Ta (100nm)

|

Ta (%) |

Ti (%) |

W (%) |

Mo (%) |

Cr (%) |

Fe (%) |

O (%) |

|

>99.9 |

<0.001 |

<0.001 |

<0.001 |

<0.0001 |

<0.01 |

<0.5 |

|

Powder Morphology |

Particle Size Distribution (nm) |

Specific Surface Area (m2/g) |

||||

|

D10 |

D50 |

D90 |

||||

|

Spherical |

30-60 |

80-100 |

<1000 |

≥8.0 |

||

Ta (1-10um)

|

Ta (%) |

Ti(%) |

W(%) |

Mo (%) |

Cr (%) |

Fe (%) |

O (%) |

|

>99.9 |

<0.001 |

<0.001 |

<0.001 |

<0.0001 |

<0.01 |

<0.08 |

|

Sphericity (%) |

Particle Size Distribution (um) |

Tap Density (g/cm3) |

||||

|

D10 |

D50 |

D90 |

||||

|

>94 |

>1 |

5±2 |

<10 |

≥10.5 |

||

Ta (5-25um)

|

Ta (%) |

Ti (%) |

W (%) |

Mo (%) |

Cr (%) |

Fe (%) |

O (%) |

|

>99.9 |

<0.001 |

<0.001 |

<0.001 |

<0.0001 |

<0.01 |

<0.02 |

|

Sphericity (%) |

Particle Size Distribution (um) |

Bulk Density (g/cm3) |

Tap Density (g/cm3) |

Fluidity (s/50g) |

||

|

D10 |

D50 |

D90 |

||||

|

>94 |

≥5 |

15±3 |

≤25 |

≥10.0 |

≥10.5 |

≤8.0 |

Ta (15-45um)

|

Ta (%) |

Ti (%) |

W (%) |

Mo (%) |

Cr (%) |

Fe (%) |

O (%) |

|

>99.9 |

<0.001 |

<0.001 |

<0.001 |

<0.0001 |

<0.01 |

≤0.01 |

|

Sphericity (%) |

Particle Size Distribution (um) |

Bulk Density (g/cm3) |

Tap Density (g/cm3) |

Fluidity (s/50g) |

||

|

D10 |

D50 |

D90 |

||||

|

>94 |

>15 |

30±3 |

<45 |

≥9.5 |

≥10.0 |

≤6.0 |

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

A tantalum alloy formed by adding a certain amount of tungsten to a tantalum base. The Ta-W binary alloy system is an infinite solid solution. As tungsten content is increased, the strength of the alloy increases. When it exceeds 12–14 at.%, the plasticity of the recrystallized alloy decreases significantly. Spherical tantalum-tungsten alloy powders that are commercially available are Ta-2.5W, Ta-7.5W, and Ta-10W. These alloys retain the low-temperature ductility of unalloyed tantalum and are more resistant to oxidation and stronger.

Since tantalum-tungsten alloys are stronger than unalloyed tantalum and retain the same corrosion resistance, they find extensive uses in the chemical and aerospace industries.

|

Ta |

W |

O |

N |

|

|

Ta10W |

Bal. |

9.0%-11.0% |

≤1000 ppm |

≤300 ppm |

|

Ta2.5W |

Bal. |

2.0-3.0% |

≤1000 ppm |

≤300 ppm |

|

|

Ta10W |

Ta2.5W |

|

Particle Size |

0-25 μm, 15-53 μm, 45-150 μm, or customized |

|

|

Morphology |

Spherical |

|

|

Apparent Density |

9.75 g/cm3 |

9.50 g/cm3 |

|

Tap Density |

11.02 g/cm3 |

11.00 g/cm3 |

|

Hall Flow Rate |

5.7 s/50g |

6.5 s/50g |

|

Sphericity |

≥95% |

|