Cold spray technology plays an important role in areas such as metal coating protection, additive manufacturing, and the repair of critical components.

Cold spray (CS) employs a pressurized gas to propel powder particles, typically measuring between 5–45 μm, at supersonic speeds. The particles impinge on the substrate in the solid state at comparatively low temperatures, often between room temperature and 600°C. Upon impact, the powder experiences plastic deformation and is built upon layer after layer until it forms a three-dimensional structure or coating. Unlike traditional thermal spray processes, which need material melting, cold spray enables one to deposit dense coatings at a low temperature. Consequently, it retains the chemical composition and microstructure of the raw material. And it inhibits such effects as oxidation, compositional loss, or grain growth.

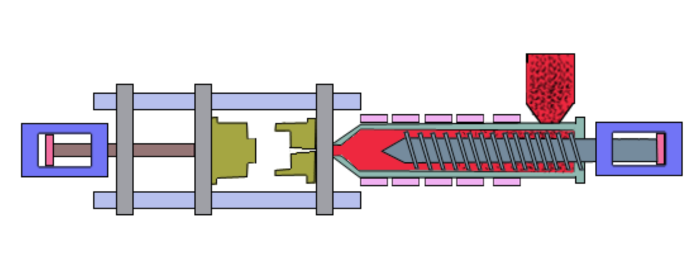

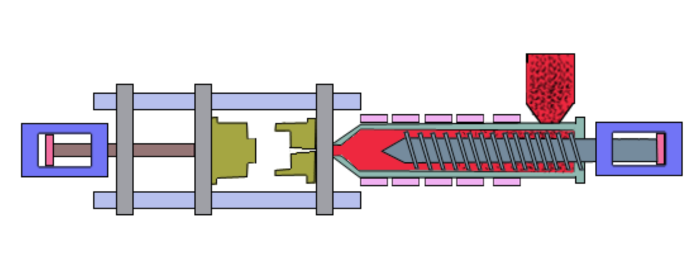

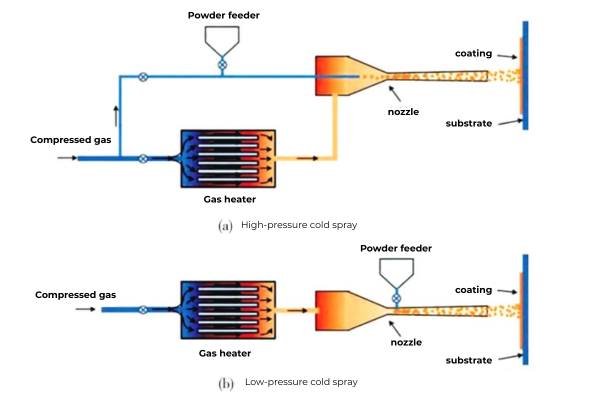

Depending on the pressure of the employed gas, cold spray can be categorized as high-pressure (working pressure more than 1 MPa) and low-pressure (lower than 1 MPa) cold spray. In the high-pressure cold spray process, the gas is first diverged and directed through a heater and a powder feeder in sequence. These streams then converge and form a supersonic gas-powder two-phase flow through a de-Laval nozzle, which facilitates the production of high-quality coatings. Low-pressure cold spray equipment is less complicated. The hot gas itself transports the powder to the nozzle, where it is sprayed. However, with the reduced temperature and lower gas pressure, the coatings resulting from pre-spraying usually have lower density and adhesion strength. Its actual use is generally limited to the repair and reinforcement of the surface of some metals, such as aluminum and copper. Accordingly, in industrial applications, "cold spray" is usually synonymous with the high-pressure cold spray process.

Fig 1. High-pressure and low-pressure cold spray

Cold spray technology is multi-material and can be utilized for coating preparation with various materials such as metals, ceramics, and polymers. The coated films tend to show excellent corrosion resistance and wear resistance, and serve to extend the service life of the substrate very effectively. The process is environmentally friendly as powder emitted during spraying can be recovered and reused. Besides, the residual stress incurred during the spraying process is negligible, even compressive, which benefits the preparation of thick coatings. Most significantly, the coating will maintain the chemical composition and microstructure of the raw material without oxidation and phase transformation. Therefore, it can be utilized for the production of thermally sensitive materials and special materials such as amorphous and nanocrystalline materials.

Cold spray is suitable for metals, ceramics, polymers, and their composite powders. Among metallic materials, aluminum, copper, titanium, nickel, and their alloys are representative.

Table 1. Cold Spray Depositable Materials (Powder)

|

Material |

Type |

|

Gold, Silver, Zinc, Copper, Tin, Nickel, Iron, Tantalum, Magnesium, Niobium, Chromium, etc. |

|

|

Alloys |

Stainless steel, Aluminum alloy, Nickel alloy, Titanium alloy, etc. |

|

Metal Matrix Composite Coatings |

Cermet, Nanocomposites, etc. |

|

Cermets |

WC-Co, NiCr-Cr₃C₂, etc. |

|

Ceramic Materials |

Metallic Glass (Ni-based, Cu-based, Fe-based, etc.) |

|

Metastable Materials |

Niobium-based amorphous alloys, Iron-based amorphous alloys |

|

Polymers |

Polyethylene, Polyolefin, etc. |

Aluminum and aluminum alloy powders have found widespread use in industrial repair due to their good plasticity, low critical velocity, and superior corrosion resistance. Research has shown that cold spray strengthening phases can be created by aluminum alloys, which further enhance mechanical properties.

Copper and copper alloy powders are highly conductive and dense close to the bulk, along with a high bonding strength, and therefore are used on a large scale for electronics, electrical power, etc.

Titanium and titanium alloy coatings must be prepared at elevated gas pressures and gas temperatures. Deposition properties and bonding strength can be significantly improved by the use of helium as the accelerating gas. Through process control, porous structures to dense films preparation are achievable in a controlled manner to meet different demands, such as biomedical or structural repair.

Nickel-based powders are usually applied to components in high-temperature conditions due to their resistance against oxidation and high strength. However, because they possess high yield strength and low plasticity, the cold spray process is not straightforward, usually also requiring higher critical particle velocities.

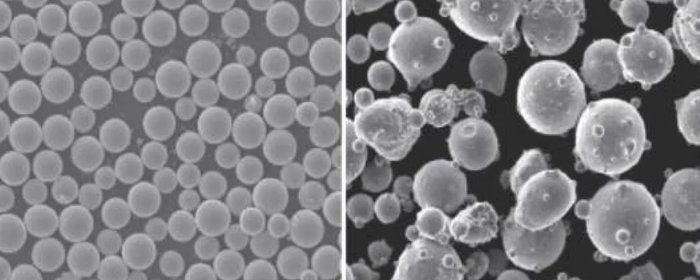

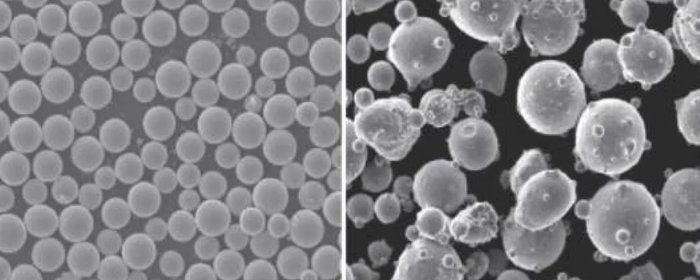

Particle size, morphology, and oxygen content of powder material are the most critical factors affecting the quality of cold spray coatings. The particle size in the case of cold spray powders generally falls between 5–45 μm. Particle size distribution affects the acceleration behavior and critical velocity of the particles directly; normally, the critical velocity will be smaller with larger particle size. Due to increased difficulty in accelerating larger particles and larger heat capacity, the deposition efficiency of larger particles will normally be smaller. Therefore, finer powders are applied to enhance deposition efficiency.

Powder morphology also plays an important role in coating properties. In low-energy spray conditions, irregular-shaped powders serve to minimize coating porosity. While at high-energy conditions, spherical powders generally have superior deposition effects because of their better acceleration properties and deformation behavior. Additionally, low oxygen content powders are more favorable for producing high-quality deposition. Thus, powder storage needs to be isolated from oxygen to avoid oxidation.

Fig 2. Damaged parts before and after CS repair

1. Electronics Field

The electronics industry utilizes cold spray technology to rapidly spray silver coatings onto target backings. Cold spray direct forming of targets offers high production efficiency, high relative density, and good bonding with the backing. The internal grain structure of the target is uniform and fine, free of defective structures, and the deposition efficiency is relatively high. Currently, large metal sputtering targets directly formed by cold spray are widely used in the electronics and information industries, such as integrated circuits, information storage, liquid crystal displays, laser memory, electronic control devices, glass coating, and other fields.

2. Shipbuilding Field

Cold spray technology can form protective coatings with good oxidation resistance and high corrosion resistance on ship surfaces, effectively reducing corrosion caused by prolonged immersion in seawater or freshwater and increasing vessel service life.

3. Automotive Manufacturing Field

Cold spray technology can reduce corrosion and wear of automotive components, effectively improving their service life, thereby enhancing overall vehicle performance and extending the vehicle's lifespan.

4. Repair Field

Repairing anti-corrosion layers of civil aircraft, civilian ships, energy equipment, and large mechanical equipment, addressing issues of magnesium or aluminum substrate loss caused by environmental corrosion and wear.

Table 2. Corresponding uses of cold spray materials

|

Material |

Uses |

|

Silver, Copper |

Conductive layers, high-power electronics, sensor heat dissipation layers, anti-corrosion protection |

|

Aluminum, Magnesium alloys |

Repair |

|

Aluminum, Titanium alloys |

Additive manufacturing |

|

Copper, Steel |

Injection molding / die-casting mold manufacturing |

|

Tantalum, Niobium, Copper alloys |

Rapid prototyping manufacturing, sputtering targets |

|

Nickel, Tantalum, High-chromium steel |

Anodic corrosion protection |

|

Zinc, Aluminum alloys |

Anodic corrosion protection |

|

Copper alloys |

Tribological performance, anti-cavitation performance |

|

Ferritic steel, Austenitic steel |

Repair, magnetic properties |

|

Nickel alloys |

Hot gas corrosion protection, repair |

|

Titanium alloys |

Biocompatible components |

Cold spray technology has been very successful. However, it also has some disadvantages. First, the equipment cost is high. This is especially true when helium is used as the accelerating gas. Second, the deposition efficiency is low for some hard and brittle materials.

Despite this, researchers continue to work. Materials science and manufacturing technology will only improve going forward. This is expected to lead to more efficient and cheaper cold spray processes and equipment.

Stanford Advanced Materials (SAM) provides an assortment of copper, tantalum, niobium, nickel, and titanium metal and alloy powders. Particle size, morphology, and oxygen content can be tailored according to the customer's needs. For further details, please Get A Quote.

1. Which materials are suitable for cold spraying to process?

This coating process does not cause thermal segregation to the substrate. Therefore, it is highly suitable for sensitive materials that would deform or undergo property change under high temperature.

2. What is the fundamental difference between cold spraying and thermal spraying?

Thermal spraying is one process in which powder or wire material is melted or softened and sprayed onto a surface. Cold spraying does not melt the powder. It uses pressurized gas to propel powder particles at high speeds to make them impact the substrate surface and form a coating.