Metal powder usage rate has always been a critical issue in 3D printing. Compared to traditional manufacturing, powder bed fusion technology is heavier on the pockets, with the cost of powder being a significant factor. Additive manufacturing has one specific aspect. It is that even in producing single components, metal powder must be prepared to accommodate the build chamber height equivalent to the part size. As a result, the usage rate of metal 3D printing powder is relatively low.

A study tested 70 printed parts and tested different powder volumes for 316L and Ti6Al4V materials. The study revealed that between 45% and 80% of the powder remained unused in building the model[1]. This is evidence that recycling and reuse of powder is an effective way to reduce costs and shorten production times.

From an environmental perspective, recycling metal powder also saves energy consumed in mining. The majority of metals, such as tungsten, tantalum, and titanium, are rare, and their recycling can alleviate the strain on resources.

Fig 1. 3D Printing

It certainly has an impact, but to what extent is debatable. A few experiments have tried to look into powder recycling impacts. As an example, we utilize a 316L stainless steel powder recycling investigation[2].

The study subjected 316L stainless steel powder to 30 recycling cycles of LPBF, with sieving (≤63μm) and addition of fresh powder after each cycle. New powder, 15-cycle recycled powder, and 30-cycle recycled powder were compared in terms of particle size distribution, oxygen content, surface oxides, and ferrite content (EBSD). Powder properties were also evaluated.

The greatest difference of 316L stainless steel powder from other metallic powders is that it consists of a SiO₂ oxide layer on the surface. With repeated cycling, the oxygen content on the surface of the powder increased. After 30 cycles of cycling, the oxygen content on the powder surface increased from 442 ppm to 487 ppm, ~10% increase. And the ferrite content also increased slightly. But the changes were minimal, with element changes within measurement error limits.

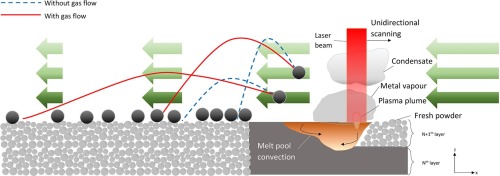

No matter by SLM or EBM, 316L stainless steel powder underwent an increase in average particle size. And the particle size distribution generally narrowed or remained basically unchanged. D50 increased from 32μm to 36μm (laser diffraction) after 30 cycles, and the fine particle content (<20μm) decreased. The reason is that small particles fill in the gap of large particles during the process of powder spreading, and they are consumed progressively. Meanwhile, splattering, agglomeration, and remelting during printing contributed to the number of larger particles, as shown in Fig. 2.

Fig 2. Splattering During Printing[3]

As recycling cycles increased, the flowability of the powder, surface morphology, and chemical composition underwent some development. That being said, tensile properties of parts made from recycled 316L powder had little variation with parts made from virgin powder, with tensile strength sometimes even being improved.

Conclusion: There is some effect, but it can be minimized by controlling recycling conditions.

Different metal powders have different recycling methods.

Method: Inert gas-protected sieving + Dynamic airflow separation + Fresh powder blending

Method: Electrostatic separation + Low-temperature drying + Flow aid

Method: Plasma spheroidization + Hydrogenation-dehydrogenation + Vacuum sieving

Method: High-temperature annealing + Chemical cleaning + Magnetic separation

Recycling metal powders is the foundation of sustainable 3D printing, balancing cost savings with material performance. Although some properties change, optimized processes can minimize effects. Advances in recycling technology will continue to improve efficiency and facilitate greener manufacturing. Stanford Advanced Materials (SAM) offers a variety of metal 3D printing powders. Get A Quote for more information.

[1] Markovits, Tamás. (2024). Analysis of printing time components and powder utilisation efficiency of metal selective laser melting process in case of 316L and Ti6Al4V materials. Virtual and Physical Prototyping. 19. 10.1080/17452759.2024.2366508.

[2] Rory Douglas, Nicholas Barnard, Nicholas Lavery, James Sullivan, The effect of powder recycling on the mechanical performance of laser powder bed fused stainless steel 316L, Additive Manufacturing, Volume 88, 2024, 104245,ISSN 2214-8604, https://doi.org/10.1016/j.addma.2024.104245.

[3] Ahmad Bin Anwar, Quang-Cuong Pham, Study of the spatter distribution on the powder bed during selective laser melting, Additive Manufacturing, Volume 22,

2018, Pages 86-97, ISSN 2214-8604, https://doi.org/10.1016/j.addma.2018.04.036.

United States

.png)