Additive manufacturing technology (3D printing), being the most promising cutting-edge manufacturing technology, is transforming traditional concepts in processing. Metal powder, the primary raw material for additive manufacturing, has a significant impact on the performance of the final product. However, during the preparation of metal powder, a type of defective particle known as "satellite particles" often forms quietly, becoming a critical factor that restricts the stability of additive manufacturing processes and product quality. Why do satellite particles occur, and what impact do they have? How can we be able to suppress their adverse effects?

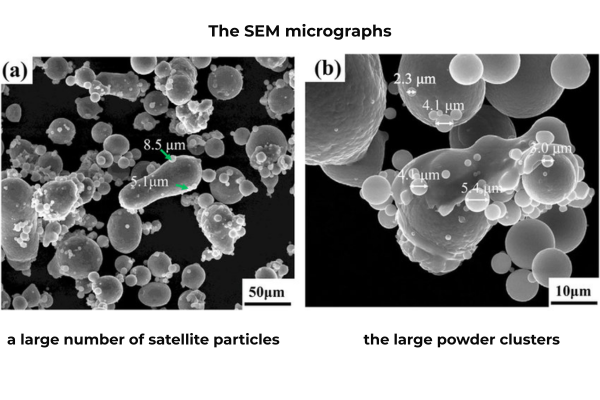

Satellite particles are aggregate particles formed when small particles attach themselves to the surface of large ones during metal powder preparation. They resemble satellites orbiting a planet, and that is where the name satellite particles comes from. It is particularly prevalent in gas atomization (GA). Ideal metal additive manufacturing powder should exhibit high sphericity, good flowability, and uniform particle size distribution. It goes without saying that the presence of satellite particles negates these ideal characteristics directly.

Fig 1. Microscopic appearance of satellite powder[1]

The influence of satellite particles on additive manufacturing processes is wide-ranging.

They first affect powder flowability. The coarse surface of satellite particles increases interparticle friction, and that leads to poor powder flowability. In laser metal deposition (LMD) processes, poor flowability can cause irregular powder feeding, leading to cracks and pores in printed layers.

Furthermore, the presence of satellite particles compromises powder bed uniformity. In powder-bed techniques such as electron beam selective melting (EBSM) and selective laser melting (SLM), satellite particles create void clusters in the powder bed, reducing the relative density of printed goods and inducing structural defects.

In addition, satellite particles disrupt the regular geometric shape of the powder. This affects the packing density of powder, thus impacting energy absorption and melt pool stability in the melting process.

Satellite particle formation results from the combined action of a number of mechanisms operating together. The prime mechanisms are:

It has been revealed by research that macroscale recirculation is the dominating source of satellite particle formation, generating approximately 70% of these particles.

When addressing the satellite particle formation mechanisms, a multi-level control strategy can be applied.

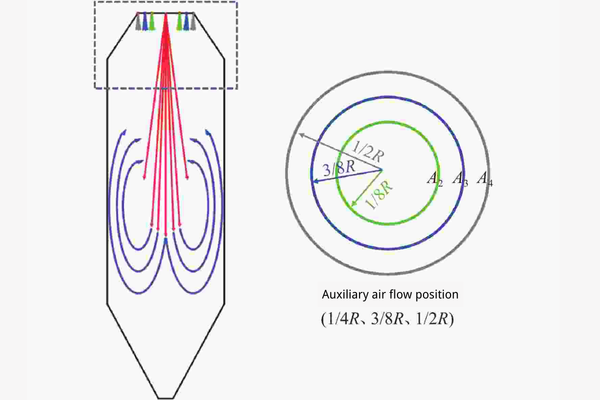

We should create ways to suppress macroscale recirculation. One of the traditional methods is to create an optimal gas flow field in the atomization chamber with the purpose of reducing the secondary entrainment of small particles.

Besides that, limiting the "adhesion-susceptible" time can also limit satellite particle formation. This involves the optimization of process parameters. This is usually done by altering parameters such as atomization pressure and melt superheat to control droplet solidification rates.

In the event that satellite particles have already been formed, these can be eliminated by mechanical sieving or air classification. In this case again, this method does not eliminate the cause but eliminates the effects.

Fig 2. Satellite powder control technology based on gas rectification[2]

As a potential quality disruptor within metal additive manufacturing, satellite particle control has an immediate association with process stability and final product performance. With advancements in characterization techniques and growing research into atomization mechanism studies, satellite particles are increasingly being addressed by a comprehensive approach of "process optimization-equipment improvement-accurate characterization." With time, the development of intelligent online monitoring systems and new atomization equipment will be capable of controlling satellite particles in real-time, providing high-quality powder materials for high-quality metal additive manufacturing.

Stanford Advanced Materials (SAM) provides 3D printing powders with high sphericity, uniform particle size distribution, and minimal satellite particles. Request a quote or learn more.

[1] Chu, Fuzhong & Zhang, Kai & Shen, Haopeng & Liu, Meijuan & Huang, Wenjing & Zhang, Xi & Liang, Enquan & Zhou, Zongyan & Lei, Liming & Hou, Juan & Huang, Aijun. (2021). Influence of Satellite and Agglomeration of Powder on the Processability of AlSi10Mg Powder in Laser Powder Bed Fusion. Journal of Materials Research and Technology. 11. 10.1016/j.jmrt.2021.02.015.

[2] HE Xin-yu, LI Xing-gang, Huang Yu-he, ZHU Qiang. Satellite-particle control technique based on gas-flow-regulation during gas atomization process[J]. Powder Metallurgy Technology, 2022, 40(4): 302-317.

United States

.png)