From the tiny gears of mobile phones to complex components in aerospace, metal part manufacturing is seeing a silent revolution. Metal Injection Molding (MIM) and Metal 3D Printing are two leading technologies applied to severe uses in high-accuracy mass production and customized production, respectively. Although they have similar-sounding names, they are very different. So, which one is suitable for your production needs?

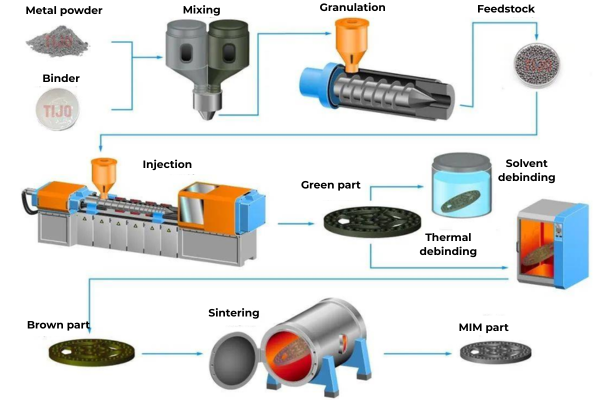

Metal injection molding is a process that combines the benefits of powdered metal and plastic injection molding. The process starts from mixing the metal powders along with a binder to form a feedstock. The feedstock is injected into a mold by precise machinery. The shape is formed before the binder is removed in a debinding process under control. Finally, the parts are sintered at high temperature to weld the metal particles. This process is characterized by high precision and reproducibility in making small, complex components.

Fig 1. Metal Injection Molding Process

There are certain advantages to metal injection molding. It can produce large amounts of parts with acceptable dimensional tolerances. The process yields parts with consistent mechanical properties. There are some drawbacks, however. Tooling costs can be costly. The process is not as favorable for rapid design changes with the need for special molds. Small production quantities may not be profitable.

Metal injection molded parts are common in consumer electronics, automotive components, and medical devices. For instance, small gears, valves, and surgical instruments are manufactured with this method. An automotive firm may use it to produce complex brackets, while a medical device manufacturer might create miniaturized implants. The method offers a good balance of precision and efficiency when producing large numbers of parts.

Metal 3D printing is an advanced technique that builds metal parts layer by layer. It uses laser or electron beam techniques to fuse metal powder directly into the desired shape. This method does not need molds or tooling. It is ideal for producing parts with intricate internal geometries and custom designs. Metal 3D printing is popular for low-volume and one-off parts.

Fig 2. Metal 3D Printing

Metal 3D printing has several advantages. It offers great flexibility in design, which allows for extremely complex shapes that are hard or impossible to create with traditional methods. The process does not require costly molds, which reduces the initial investment. On the other hand, printing can be slower per part. The surface finish may require extra work, and production costs can be higher for large runs compared to traditional methods.

This method is used in aerospace, medical, and high-performance automotive industries. An aerospace company might print lightweight parts with internal cooling channels. Medical professionals use it for custom implants and prosthetics. Automotive engineers might produce components with complex shapes for better performance. These applications benefit from the method’s ability to produce parts that cannot be made easily with other technologies.

In our previous article, we provided a detailed introduction to Metal Injection Molding (MIM). Now, let’s take a deeper look at how it compares to Metal 3D Printing.

Both injection molding and 3D printing use metal powders. In injection molding, the metal powder is mixed with a binder and later sintered. In 3D printing, pure metal powders fuse directly with high-energy beams. The end material properties differ.

Injection molded parts usually have very high densities and consistent microstructures, while printed parts may have slight variations in density depending on the printing parameters used. However, material choices for both processes often include stainless steel, titanium, nickel alloys, and cobalt chrome.

Stanford Advanced Materials (SAM) can customize the above metal powders in terms of particle size, sphericity, purity, etc.

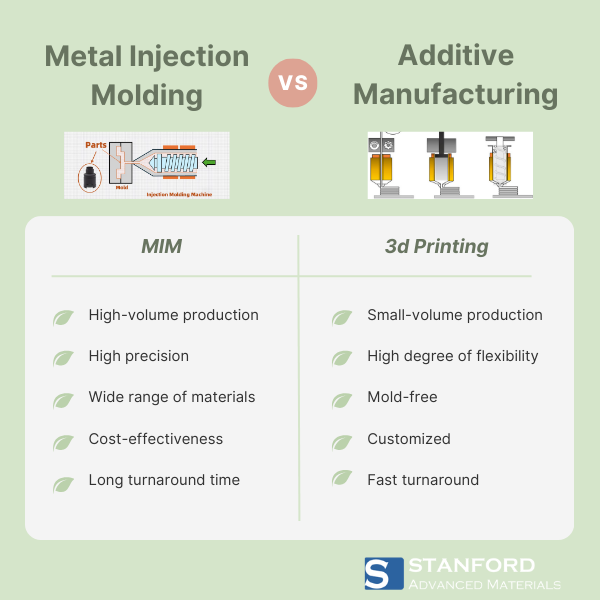

Design freedom is a major difference between the two methods. Metal three-dimensional printing allows for very complex internal channels, lattice structures, and intricate details. Injection molding is limited by the need for molds and the flow characteristics of the feedstock. With 3D printing, there is more room for creative and functional designs. However, injection molding produces parts with high repeatability when the design is finalized and production volumes are high.

When comparing costs, volume plays a big role. Metal injection molding requires expensive molds and setup costs. This method is cost-effective only when producing high volumes of parts. Metal three-dimensional printing does not require molds, which reduces initial investments. However, printing each part can be time-consuming and more expensive for larger runs. For low-volume, customized production, 3D printing often proves to be more attractive despite the per-part cost.

But in some high-performance fields, metal 3D printing has even begun to be used to manufacture critical components. Although these parts may be mass-produced, their design complexity makes 3D printing the best or even the only viable option. Therefore, 3D printing is not just "popular for" small-batch production but is expanding into broader manufacturing areas.

Overall, Metal Injection Molding is superior for mass producing small, accurate parts with excellent material properties at an affordable cost, but with significant up-front investments in molds. By contrast, Metal 3D Printing offers unparalleled design freedom, rapid prototyping, and support for low-volume complex or tailored parts with no tooling. Though MIM remains the sweetheart of mass production, 3D printing is rapidly closing the gap by taking on more intricate production tasks. Ultimately, the choice between these technologies depends on parameters such as production volume, design complexity, material requirements, and cost considerations, with each technology carving out its own niche in manufacturing for the future.

United States

.png)