Metal Injection Molding (MIM) has the following benefits: high accuracy, high strength, low expense, high design freedom, and light weight. It has extensive applications in the medical, automobile, consumer electronics, and new robotics markets.

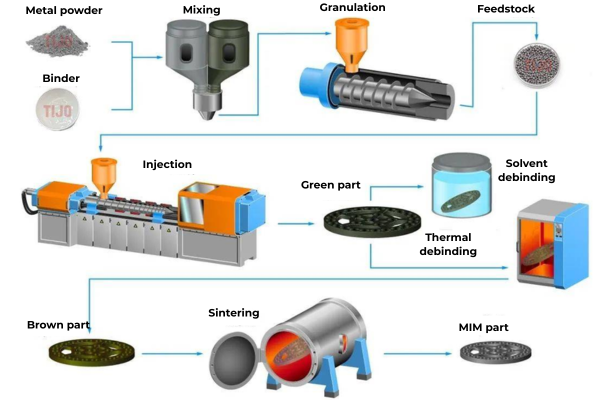

Metal Injection Molding (MIM) is a forming process that combines plastic injection molding with powder metallurgy. Specifically, the process involves mixing metal powder with an organic binder, granulating the mixture, and then injecting it into a mold cavity in plasticized and heated form to create a solid shape. The binder is then removed after forming, and sintering is then done to obtain the final product. Figure 1 illustrates the specific process flow.

Fig 1. Metal Injection Molding Process

Metal injection molding is a highly complex process. The following are keys that require serious focus in this process:

Traditional powder metallurgy is the equivalent of "compaction + sintering" and is used mainly to produce parts of low structural complexity. Metal injection molding is, by analogy, similar to "plastic injection molding + sintering," enabling economical single-step production of small, three-dimensional, and intricate complex parts. This is the foremost difference between them. Also, the metal powder used in MIM typically has a particle size between 0.5–20 μm. In theory, the smaller particles have a greater specific surface area and are therefore easier to form and sinter. Traditional powder metallurgy uses powders of larger size larger than 40 μm.

Metal injection molding requires initial production of molds and is most suitable for mass production. Its cost savings are coming from economies of scale. The difference is, metal 3D printing does not involve the use of molds and can create parts from digital files directly. 3D printing is optimally applied for small quantities, custom-made, or highly intricate designs, but is more costly on a per-unit basis.

Metal Injection Molding vs. Metal 3D Printing

|

Metal Injection Molding (MIM) |

Metal 3D Printing |

|

Cost-effective for mass production |

Cost-effective for prototyping |

|

Mold cost: $50,000–100,000 |

No mold required |

|

Suitable for smaller, thin-walled, lightweight parts |

Capable of producing larger parts |

|

Not suitable for prototyping and small batches |

Ideal for frequently modified parts |

|

Powder particle size < 20 μm |

Powder particle size 20–45 μm |

|

Excellent surface finish |

Surface finish inferior to MIM |

The metal materials used in Metal Injection Molding (MIM) are extensive but must meet two core criteria: ① ability to be made into fine spherical powder; ② suitability for sintering in terms of metallurgical properties.

Based on these criteria, the most commonly used metal materials include:

1. Stainless Steel Powders: The most widely used category with high cost-effectiveness.

2. Tool Steel Powders: Used for applications requiring high hardness, wear resistance, and red hardness.

3. Cobalt-Chromium Alloy Powders: These hard metals are used for extremely wear-resistant cutting tools, drill bits, and mold inserts.

4. Titanium and Titanium Alloy Powders: Such as Ti-6Al-4V, known for good biocompatibility and high strength-to-weight ratio, primarily used in aerospace and medical implants.

5. Nickel-Based Powders: Offer excellent high-temperature strength and are used for hot-end components like jet engine and gas turbine blades.

Metal Injection Molding combines the structural strength of metals with the design flexibility of plastics, providing a revolutionary manufacturing solution for industries requiring lightweight, high-strength, and highly integrated functionalities.

Metal injection molding plays a key role in producing parts for the medical field. It is often used to produce implants, surgical tools, and intricate components. A common case is the production of tiny parts used in orthopedic implants. For instance, titanium parts made by this process show high strength and built-in resistance to corrosion. These implants often have porosity that helps with the integration of bone tissue. The process also produces parts for dental implants and other instruments. The method helps to achieve cost effectiveness when many small, high-quality parts are needed.

Many medical instruments made with metal injection molding have detailed geometry. They serve functions that classic machining may not achieve. In one well-known case, surgeons use small stainless steel instruments made accurately using this method. The parts are smooth, consistent, and reliable. They can also be made from cobalt-chromium, a strong alloy with good wear resistance. This is important for parts that experience heavy use during procedures. Many hospitals count on these parts to boost the performance of medical devices.

Fig 2. surgical tools

The automotive industry values metal injection molding because it handles complex shapes well. Many engine components, fasteners, and transmission parts are produced by this method. For example, some gear components and valve train parts made of stainless steel or tool steel show excellent wear resistance and performance. Metal injection molding has been used to make parts that can withstand high temperatures and stress. This is important in the harsh car environment.

Using metal injection molding, the parts have high precision and strong mechanical properties. The process ensures that even the smallest parts have a uniform structure. Automotive companies often choose this method for the production of brake components and fuel injector parts. The method helps reduce the number of steps needed for a part to reach final form, saving time and cost. This efficiency is a great benefit to manufacturers who need many parts with exact details.

Fig 3. Engine components

Consumer electronics benefit from metal injection molding as well. It is used to produce small components that need intricate and compact designs. The method works well for items that require excellent dimensional accuracy. Common examples include parts in laptops, smartphones, and portable devices. Devices often require precise metal frames and tiny connectors, whose parts are made in high volumes and need attention to quality.

The process suits the production of casings and internal structures. Many components are made of stainless steel or copper alloys, chosen for their strength and good electrical properties. The parts have tight tolerances and can handle frequent use. In one common application, small circuit connector housings are produced with this method. The parts stand up to repeated handling and frequent cycles.

Hinges are critical components of foldable screens. The manufacturing of hinges commonly involves multiple processes such as MIM, stamping, and CNC precision machining. Compared to CNC machining, the MIM process reduces costs by 30%-50% and achieves a material utilization rate of over 95%. Additionally, MIM significantly reduces the number of parts in hinge assemblies. The application of MIM products in AI glasses and smart watches is expected to occupy an increasingly larger share.

Fig 4. AI glasses hinge

Robotics has used metal injection molding for a long time. The method helps produce lightweight parts with high strength. Robotic components such as gear systems, joints, and connectors rely on strong materials. Titanium and stainless steel parts made by this process show excellent performance.

Many robotic arms and mobile robots use parts produced by metal injection molding. They benefit from the high precision and tight tolerances of the process. In some cases, the parts can have built-in channels for wiring. This adds to the compact design of robotic machines. Robots in assembly lines use these parts because they offer repeated accuracy and durability throughout a long working life.

Metal injection molding also aids in reducing parts count by producing multi-functional components. This simplification leads to more reliable and easier-to-maintain robotic systems. The process also allows designers to create parts with a special surface finish. This finish reduces friction in moving parts. The result is smoother operation for vibration-sensitive robots.

F: What is metal injection molding used in medicine?

Q: It is used for implants, dental parts, and surgical tools with high precision and consistent strength.

F: How does metal injection molding help the automotive industry?

Q: It produces complex engine parts, fasteners, and transmission components with high durability and exact geometries.

F: Why is metal injection molding important in robotics?

Q: It creates lightweight and strong parts with precise tolerances, aiding in the design of flexible and durable robotic systems.

United States

.png)