Have you ever wondered if any material has the higher electrical conductivity of silver with the economic cost of copper? In modern industrial manufacturing, engineers have searched for a best-of-both-worlds strategy. It is where silver-coated copper powder comes into play.

Silver-coated copper powder is a special composite material. Inside it is copper metal powder, uniformly covered with an outside layer of silver. This arrangement has numerous advantages.

1. Significant cost reduction. Silver is a costly metal and is very pricey. Copper, on the other hand, is a common metal and much less expensive. Since silver-coated copper powder uses only a thin coating of silver to encase an enormous amount of copper, the overall expense is much lower than that of pure silver powder. This incurs a significant amount of cost savings for the companies in terms of materials.

2. Excellent electrical conductivity. Silver is the most electrically conductive metal in the world. Electric current possesses a "skin effect," which is that it will always seek to go on the surface of a conductor. The surface of silver-coated copper powder consists of highly conductive silver so that it will work almost as well as pure silver powder.

3. Strong oxidation resistance. Copper powder can be oxidized and rusted easily, and such corrosion lowers its electrical conductivity. Silver is chemically inert and less likely to oxidize. The coating of silver serves as protective clothing for the copper powder, keeping the inner copper away from oxidation and maintaining long-term conductivity.

4. Good processability. Silver-coated copper powder is well solderable and can be easily linked to other metals. It also tolerates stable performance at high temperatures, hence it can be processed using various methods.

All these advantages make silver-coated copper powder usable in most industries.

Its most notable application is in the manufacture of solar panels. Solar cells require a lot of conductive silver paste in order to collect an electric current. The replacement of part of the pure silver powder with silver-coated copper powder saves a tremendous amount of money on the manufacturing of solar cells and makes solar power cheaper.

It is also used in electronic components. For example, in the electrode materials of multilayer ceramic capacitors, silver-coated copper powder can reduce cost without compromising on performance.

Similarly, in electromagnetic shielding materials, silver-coated copper powder can be used to create shielding coats that protect electronic devices from interference. In 3D printing, it can be a useful material for metal printing since it can be used as a conductor. The spherical silver-coated copper powder provided by Stanford Advanced Materials (SAM) is highly suitable for 3D printing. Additionally, it can be used in high-performance applications such as thermal interface materials and EMI shielding.

* Understand the difference between spherical silver powder and flake silver powder: Spherical Silver Powder and Flake Silver Powder

The quality of the silver layer will determine the performance of the product. If the silver coating has not been done, then the inner copper will oxidize, and hence the material will fail.

In order to ensure the thickness of the silver layer, the manufacturing process uses an electroless plating technique. The even deposition of the silver layer on each particle of copper powder is ensured through this process. During manufacturing, precise control over parameters such as temperature, time, and solution concentration is needed. Only by strictly controlling these conditions can high-quality products with a whole and pore-free silver layer be manufactured.

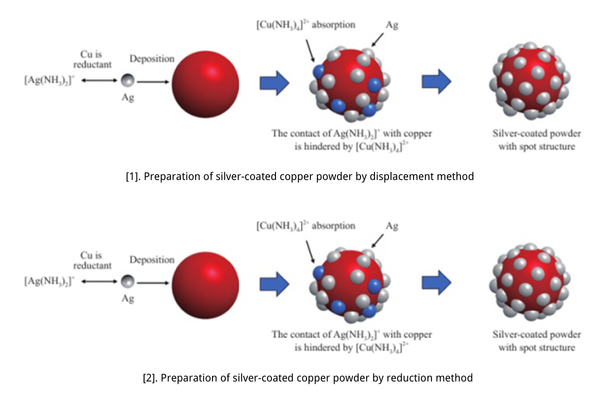

Electroless plating is presently the most prevalent method to form silver-coated copper powder. Based on the mechanism of deposition, electroless plating can be divided into two categories: displacement and reduction, as depicted in the following figure:

The most remarkable advantage of silver-coated copper powder is that it significantly reduces material costs while maintaining performance nearly at the same level as pure silver. It cleverly capitalizes on silver's "high stability and high conductivity" and copper's "low cost and high conductivity" to reap a synergistic advantage such that 1+1>2. It is of revolutionary significance to mass-production manufacturing industries that are very cost-sensitive, such as the photovoltaic industry.

United States

.png)