Nano Silver Flake is a high-performance conductive filling material with good oxidation resistance. Stanford Advanced Materials (SAM) offers high-quality Nano Silver Flake with competitive pricing.

Related products: Spherical Silver Powder

Nano Silver Flake is a high-performance conductive filling material with good oxidation resistance. Stanford Advanced Materials (SAM) offers high-quality Nano Silver Flake with competitive pricing.

Related products: Spherical Silver Powder

Nano Silver Flake is silver of small, flat, and plate-like particles at the nanolevel. Nano Silver Flake is characterized by low bulk ratio and good liquidity. The silver powder conductive layer surface is smooth and has good conductivity. Nano Silver Flake is a high-performance conductive filling material with good oxidation resistance. It is extensively used in electronic paste, the conductivity of electronic products, electromagnetic shields, antibacterials, and antivirus.

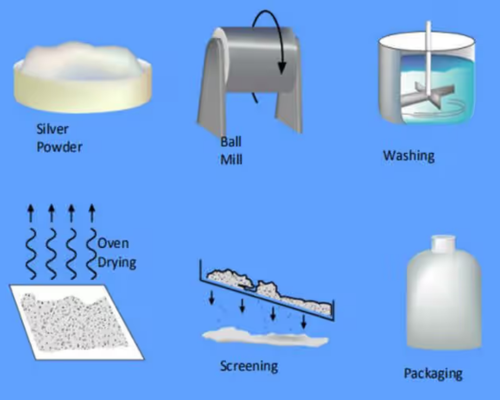

Flake silver powder is produced by mechanically rolling (ball milling or roller compaction) spherical silver powder into flat flake structures, followed by classification and surface treatment. The resulting flakes achieve an aspect ratio of 50:1~100:1 with 3-5 times increased specific surface area.

|

Name |

Nano Silver Powder |

Nano Silver Flake |

Submicron Silver Powder |

||

|

Average Particle Size |

50nm, 80nm |

1-1.3μm |

0.5-1μm |

100nm/3μm |

400 nm |

|

Purity |

99.9 |

99.5-99.999 |

99 |

99.99 |

99.99 |

|

Shape |

Nearly spherical |

customized |

Spherical |

Flake |

Spherical |

|

Specific Surface Area (m2/g) |

30 |

- |

0.4-1.5 |

1.03 |

0.92 |

|

Bulk Density (g/cm3) |

1.24 |

- |

- |

0.91 |

3.81 |

|

Tap Density (g/cm3) |

3.39 |

- |

- |

- |

- |

Our Nano Silver Flake is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Q: What is the difference between silver flake and silver powder?

Silver powder consists of spherical particles, typically 0.1-20μm, with good packing density and flowability, applicable to high-temperature sintering, such as photovoltaic front-side pastes.

Silver flake possesses flat, plate-like geometries with high aspect ratios, enabling low filler loading (30-50%) for conductive networks, which is preferred for low-cure applications, i.e., printed flexible circuits.

Q: What is more conductive, spherical silver powder or flake silver powder?

Spherical silver powder is more conductive due to the tight particle fusion in high-temperature sintering. Flake silver powder is less initially resistant at low filler loads due to its large contact area but requires sintering to match spherical powder performance.