Metal 3D printing technology is reshaping modern manufacturing. However, parts taken directly from the printer often cannot be used immediately. Their surface quality usually requires further processing to meet end-use requirements.

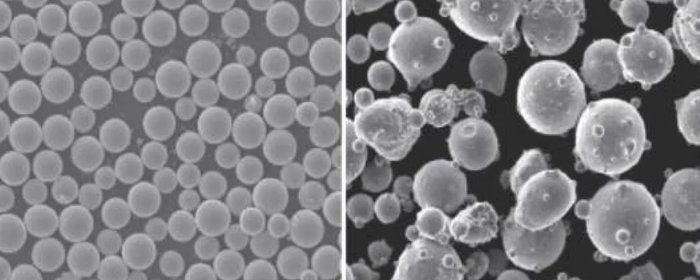

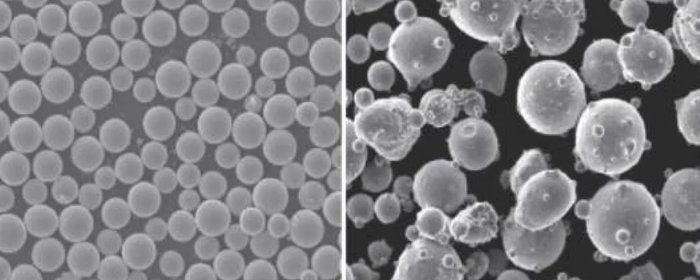

Metal 3D printed parts develop unique surface characteristics during forming. These features directly affect the part's performance. First, due to the layer-by-layer manufacturing principle, stair-step effects appear on the surface. This effect occurs because the 3D model is split into multiple 2D layers for printing. It creates tiny step-like textures on sloped or curved surfaces. Additionally, some metal powder may not fully melt during printing. These particles adhere to the surface, further increasing roughness.

More importantly, rapid melting and cooling during printing can cause micro-defects on and near the surface. These defects include pores, lack-of-fusion zones, and micro-cracks. They become stress concentration points and significantly reduce the part's fatigue life.

Besides mechanical properties, surface quality also affects functional performance. Marks left after support removal need to be eliminated. Deformation caused by thermal stress must be corrected. For parts handling fluid flow, inner surface roughness directly affects flow behavior and increases pressure loss. In the medical field, the surface finish of implants influences both biocompatibility and tissue healing.

Therefore, the core purpose of surface treatment is to address the aforementioned issues, aiming to:

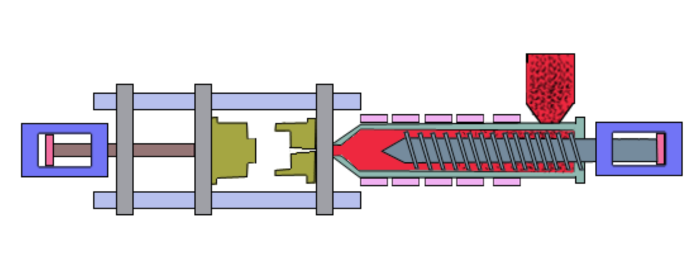

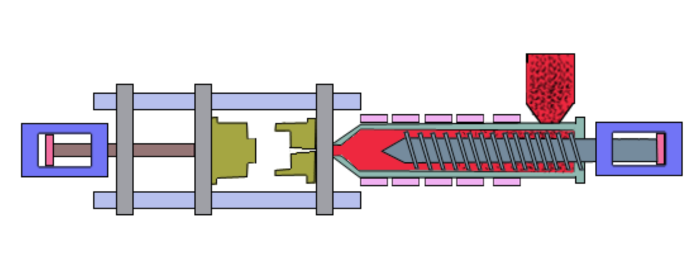

Abrasive flow machining (AFM) is especially suitable for parts with complex internal channels. It works by forcing a semi-fluid abrasive medium under pressure through the surface to be processed. The abrasive uniformly grinds and polishes the channel surface. A typical application is the cooling channels of rocket engines. After abrasive flow processing, the inner surface roughness can be reduced from Ra 12μm to Ra 0.8μm, significantly improving coolant flow efficiency.

Shot peening is a high-precision surface treatment technology. It attempts to improve the quality and performance of the surface by using fine physical impacts. The process begins with the cleaning of the surface to clean away the oil, rust, and impurities. Deburring is also done to smooth the surface. The part is then loaded into a shot peening machine afterwards. Fine glass beads or other hard particles like steel shots or ceramic beads are driven at high velocity onto the part surface by high-pressure air. Shot peening forms compressive stress on the surface, which actually increases fatigue strength.

Electrochemical polishing is based on the basis of anodic dissolution. The part is immersed as an anode in a specific electrolyte. When current is applied, higher current density at microscopic peaks causes faster dissolution, resulting in leveling. This method is particularly suitable for stainless steel and cobalt-chromium alloys. It can achieve a mirror-like finish. Note that electrolyte composition, temperature, and current density must be precisely controlled. Otherwise, defects like over-corrosion or pitting may occur. Electrochemical polishing not only produces a uniform, smooth, and highly reflective surface but also allows precise control over material removal thickness. The thickness typically ranges from 0.0001 to 0.0025 inches.

Non-contact processing is carried out through laser polishing. The surface is rapidly scanned with a laser beam, where an extremely thin layer of material is melted and then levels because of surface tension. Laser polishing works well for processing complex contours, but it requires a massive investment in machinery. Currently, it is used mainly on expensive precision parts such as medical devices and optics molds.

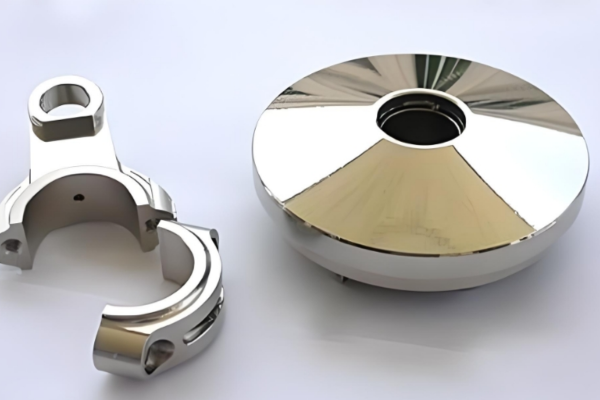

Electroless nickel plating deposits an evenly dense layer of nickel on metal substrates through chemical reaction rather than typical electrolysis. The operation is especially well-suited for complex shapes or irregular surfaces that tend to be difficult to plate satisfactorily with electrolytic methods, resulting in higher corrosion resistance, oxidation resistance, and wear protection. Parts that are electroless nickel plated are finished with a bright nickel appearance. The coating not only makes the part look good, but it also increases very slightly the roughness of the base surface. Nickel coating is extremely controllable, with thickness adjusted between 0.0001 inches based on the specific application requirements.

Selecting a surface treatment process is a systematic decision process. Start with the end-use application and conditions of the part. For example, load-carrying structures prioritize fatigue life and may require shot peening. Components in fluid systems prioritize the integrity of the flow channel, and thus abrasive flow machining is a great choice. Extremely decorative components may use electrochemical polishing.

Second, study the part's geometric characteristics in depth. For internally complex-cavity parts, begin with processes that will process internal surfaces, like chemical polishing or abrasive flow machining. Avoid processes with high cutting force for thin-wall parts to prevent distortion. Material characteristics should also be considered, as different materials will respond differently to processes. Titanium alloys will accept mechanical polishing, whereas stainless steel will be more suitable for electrochemical polishing.

In actual production, there will usually be a series of processes. A typical process sequence could be: stress relief heat treatment, then support removal; sandblasting to eliminate stuck-on powder; hot isostatic pressing to eliminate internal flaws; and then select finishing processes as required, such as abrasive flow polishing for internal passages and electrochemical polishing for exterior surfaces.

Cost-effectiveness analysis is also valuable. Consider equipment investment, man-hours, material loss, and environmental cost. The most technologically advanced means is not always the cost-effective. Consider the optimum combination based on volume and quality requirements.

Surface treatment of metal 3D printing is a systematic work with project orientation. It should be decided by technical possibility and economic reasonability based on the demand of specific applications. With the continuous development of technology, newer surface treatment methods that are more efficient and precise will continue to emerge. This will promote the further industrialization of metal 3D printing technology. For any further inquiries regarding metal 3D printing or metal 3D printing powders, please consult Stanford Advanced Materials.