Metal powders have wide-ranging applications in advanced applications such as 3D printing, metal injection molding (MIM), and thermal spraying. Powder shape is one of the most significant characteristics of metal powder. It directly affects the flowability of the powder, packing density, sintering behavior, and mechanical properties of the final product. Powders produced by gas atomization, plasma atomization, and PREP are generally spherical. However, water-atomized and mechanically milled powders are typically irregular.

The process is simple. Metal is melted into liquid form and then sprayed with high-pressure gas. The molten metal breaks into numerous tiny droplets. While flying in the air, these droplets naturally contract into small spheres due to surface tension and solidify into powder.

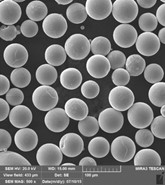

Most gas-atomized metal powders are spherical or nearly spherical. As shown in Fig. 1, the scanning electron microscope (SEM) image reveals that the particles generally have smooth surfaces. However, upon closer look, some small particles may be attached to larger ones—these are called "satellite particles." Thus, gas-atomized powders are characterized by high sphericity and smooth surfaces, though satellite particles may be present.

Fig. 1. SEM images of gas-atomized Ti-6Al-4V powder particles of nearly perfect spherical shape[1]

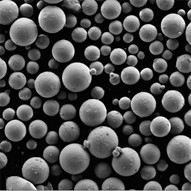

An extremely high-temperature plasma flame melts the tip of a metal rod. The molten metal is immediately broken up and blown away by the plasma stream, turning directly into powder. Plasma atomization can produce metal powders with the highest sphericity in industrial production. Unlike gas-atomized powders, plasma-atomized powders have very few satellite particles.

Fig. 2. Ti-6Al-4V powder particles produced by plasma atomization[2]

In this process, a metal electrode rod is rotated at high speed. A plasma arc melts the end of the rod, and the centrifugal force throws off the molten droplets, which form into small spheres in mid-air. PREP produces highly spherical powders (Fig. 3), exceeding that of gas-atomized powders. PREP powders have smooth and clean surfaces, almost free of satellite particles. The sphericity and purity are comparable to those of plasma-atomized powders.

Fig. 3. PREP-produced powder particles.

The key reasons lie in the differences in particle formation mechanism and cooling process.

Plasma atomization uses high-speed plasma flow to shear and impact the molten metal. The particles travel a long distance in the air, allowing sufficient time for the droplets to contract into perfect spheres under surface tension before solidifying—similar to water droplets falling from a height and forming perfect spheres in mid-air.

In PREP, centrifugal force ejects the droplets. Their flight path is shorter and tangential—like water droplets flying off a spinning umbrella. Larger droplets may hit the ground before fully spheroidizing.

Reference: Gas Atomization vs Water Atomization vs Plasma Atomization: What is the Difference

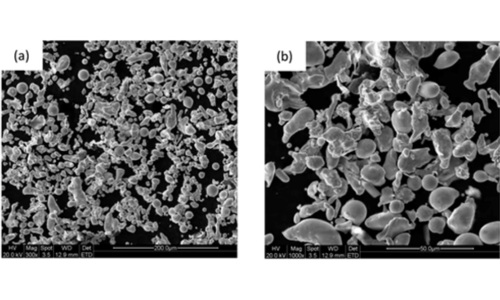

Water atomization is similar to gas atomization. Instead of gas, high-pressure water jets are used to break up the metal stream. This reduces cost but also lowers sphericity. Most water-atomized powders are irregular. Water cools the metal too rapidly—the droplets solidify before contracting into spheres. Thus, the particles appear fragmented, like shattered flakes or teardrops, with rough and uneven surfaces.

Fig. 4. Water-atomized 316L stainless steel powder. [3]

This process involves placing bulk metal into a large mill. Grinding balls crush, impact, and grind the metal into powder. The resulting powder is highly irregular and angular. It resembles various-shaped debris—some flaky, some like sharp-edged gravel—with very rough surfaces.

The choice of production method depends entirely on the intended application. Spherical powders are preferred for printing precision parts, while irregular powders are more suitable for pressing and forming. Although shape is a key factor, it is not the only one. Practical applications also require consideration of purity, oxygen content, particle size, etc.

* For more information about metal powders, please contact Stanford Advanced Materials.

Q1: Why does 3D printing prefer spherical powders?

Spherical powders are very flowable. They can spread like a liquid to create a thin, even, dense layer on the print bed. This is essential for precision printing and part density. Irregular powders may result in uneven layering and printing defects.

Q2: Are irregular powders useless?

Not at all. Although irregular powders have poor flowability, their large surface area allows more mechanical interlocking when being pressed. Their higher surface energy and internal stress also enhance sintering activity that assists densification.

Q3: Which process produces the purest powders?

Plasma atomization (PA), Plasma Rotating Electrode Process (PREP), and Electrode Induction Gas Atomization (EIGA). These methods use "crucible-free" arrangements, which avoid contamination by ceramic crucibles.

Q4: Can water-atomized powders replace gas-atomized powders in 3D printing due to lower cost?

Usually not. The non-uniformity of shape and lower flowability of water-atomized powders cause difficulties in layer spreading, resulting in pores and cracks as defects. Their higher oxygen content may not be compatible with high-end applications. Hence, these two types of powders have distinct purposes.

Q5: What is unusual about the internal structure of mechanically milled powders?

Mechanical milling is not grinding but is an intense mechanical alloying process. It produces a high number of crystal defects (dislocations), nanoscale grain boundaries, and even allows solid-state alloying of different metals. This cannot be achieved through atomization methods.

[1] Markl, Matthias & Körner, Carolin. (2018). Powder layer deposition algorithm for additive manufacturing simulations. Powder Technology. 330. 125-136. 10.1016/j.powtec.2018.02.026.

[2] Sufiiarov, Vadim & Polozov, Igor & Borisov, Evgenii & Masaylo, Dmitry. (2016). Additive manufacturing of individual implants from titanium alloy.

[3] Chen, Jibing & She, Yong & Du, Xinyu & Liu, Yanfeng & Yang, Yang & Junsheng, Yang. (2024). Influence of oxygen content on selective laser melting leading to the formation of spheroidization in additive manufacturing technology. RSC Advances. 14. 3202-3208. 10.1039/d3ra08627e.

United States

.png)