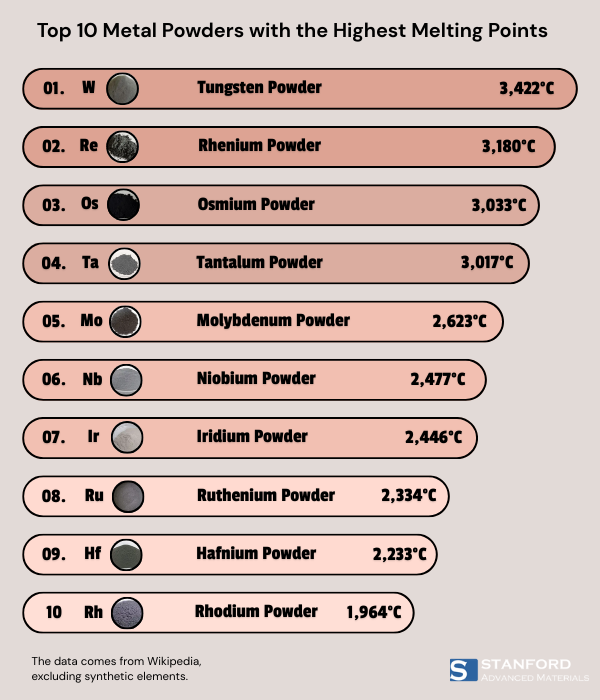

When talking about the metal with the highest melting point in the world, many people think of tungsten and tungsten light bulbs. So, what is the metal powder with the highest melting point? Here, we need to clarify one key point: the melting point of a metal powder is the same as that of its solid bulk form. The powder form increases its surface area, reactivity, and sintering performance, but it does not change its inherent physical property—the melting point. Therefore, the metal powder with the highest melting point is tungsten powder.

Besides tungsten, what other metal powders have high melting points? Let’s take a look.

Note: The following list excludes artificially synthetic elements such as lawrencium (2,961℃), fermium (2,781℃), technetium (2,200℃), and rutherfordium (2,100℃).

Tungsten powder is gray to black in color. It has the highest melting point of all metals—3422°C.[1] It also has a very high boiling point of 5927°C. Tungsten is an important refractory metal powder. Its unique properties make it widely used in alloys, electronics, and chemical industries. It not only resists high temperatures but also has extreme hardness and wear resistance. It is an ideal material for making hard alloys. Its excellent resistance to arc erosion also makes it a key material for medium- and high-voltage electrical contacts.

Rhenium powder has the second-highest melting point among metal powders. It appears silvery-white or gray-black. Its melting point is 3180°C,[2] second only to tungsten. Rhenium is one of the rarest elements in the Earth’s crust, so it is very expensive. Rhenium powder is rarely used alone. It is mainly used as a critical performance enhancer. When alloyed with tungsten or molybdenum powder through powder metallurgy, it significantly improves strength, ductility, and recrystallization temperature. These alloys are widely used in high-performance jet engines, rocket engine parts, and the electronics industry.

Osmium powder has the third-highest melting point. Osmium is also the densest metal in the world. The powder is blue-black and has a melting point of 3033°C. [3] It is very stable but also very brittle. In air, it slowly oxidizes to form highly toxic and volatile osmium tetroxide (OsO₄). So, it must be handled and stored carefully in sealed or inert environments. Osmium is used in various applications. It can make super-hard alloys. In industry, it is mainly used as a catalyst. It is often combined with other metals to improve product lifespan.

Tantalum powder ranks fourth in melting point. It is dark gray and has a very high melting point and corrosion resistance. These properties make it useful in many fields. It is important in electronics, metallurgy, steel, chemicals, hard alloys, superconductivity, automotive electronics, aerospace, medical care, and scientific research. The most important use of tantalum powder is in making tantalum capacitors. Almost half of the world’s tantalum production is used for this. High-purity tantalum powder is also used in corrosion-resistant equipment, surgical implants, and high-performance alloys.

Molybdenum powder has high strength, good electrical conductivity, and good thermal conductivity. It is a fundamental material in powder metallurgy. When added to steel powder, it improves strength, toughness, and heat resistance. Through pressing and sintering, molybdenum powder is used to make heating elements, extrusion molds, and aerospace parts.

According to global consumption data, the steel industry uses the most molybdenum—about 80% of total consumption. The chemical industry uses about 10%. Other uses include medicine, agriculture, and electronics, which together account for about 10%.

Niobium is ductile, corrosion-resistant, and has excellent superconductivity. It is mainly used as an alloy additive to improve nickel- and cobalt-based superalloys. Due to its superconductivity, niobium powder is used to make niobium-titanium (Nb-Ti) and niobium-tin (Nb₃Sn) superconducting wires. It is also used in acid-resistant equipment, electronic components, and medical implants.

Iridium powder is a shiny white platinum-group metal powder. It has a melting point of 2446°C. Iridium is the most corrosion-resistant metal known. It does not dissolve in any acid. It is very rare in the Earth’s crust and is expensive. Iridium powder is used in extreme conditions, such as in high-temperature crucibles, spark plug electrodes in rocket engines, and catalysts in the petrochemical industry. Due to its high hardness and wear resistance, it is also used as a hardening agent in platinum alloys.

Ruthenium powder is a gray-black platinum-group metal powder. It has a melting point of 2334°C. It is chemically stable, hard, and wear-resistant. Ruthenium powder is mainly used as an effective hardening agent. In electronics, adding a small amount to platinum or palladium powder improves resistivity, wear resistance, and corrosion resistance. So, it is often used in thick-film resistors, electrical contacts, and electrodes. It is also an important chemical catalyst.

Hafnium powder is gray and has a melting point of 2233°C. Hafnium is rare in the Earth’s crust and is often found with zirconium. It has good corrosion resistance and a high thermal neutron absorption cross-section. High-purity hafnium powder is used in heat-resistant niobium or tantalum alloys. It is also used in high-dielectric-constant gate materials in advanced integrated circuits.

Rhodium powder is a blue-gray, shiny precious metal powder from the platinum group. It has a melting point of 1964°C. It is highly chemically stable, has excellent catalytic activity, and strong light reflectivity. Rhodium powder is mainly used as a wear-resistant coating for high-quality scientific instruments and as a catalyst. It is also used for coating headlight reflectors, telephone relays, and pen tips. The automotive industry is a major user of rhodium. Currently, its main use is in automotive exhaust catalysts. Other industries that use rhodium include glass manufacturing, dental alloys, and jewelry.

Thank you for reading. If you want to learn about other properties of metal powders, you can check out this article: Top 10 Metal Powders: The Basics You Need to Know About Properties. For other product information, you can also contact Stanford Advanced Materials directly.