With the advancement of precision measurement technology at a fast rate, performance requirements on temperature sensors are constantly on the rise. Pt100 temperature sensors are widely applied to industrial process control, laboratory measurement, and environmental monitoring. However, conventional Pt100 sensors are not perfect in either thermal response speed or temperature uniformity. In recent years, spherical alumina powder has emerged as a new solution when it is used as a thermal filler to overcome the above shortcomings.

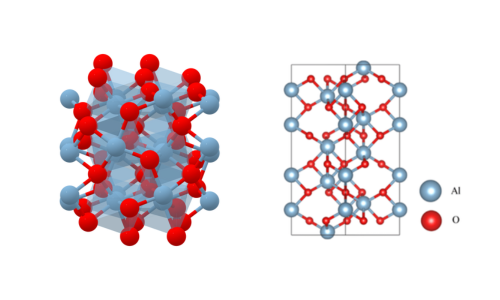

Spherical alumina (α-Al₂O₃) is high-purity alumina characterized by a well-defined spherical morphology, perfect for electronic packaging and thermal management. Its crystal structure, being predominantly in the alpha form, is a close-packed hexagonal array. This structure provides the material with great thermal stability and a melting point up to 2050°C.

Fig 1. Spherical alumina crystal structure

From a heat-transfer perspective, high-purity spherical alumina exhibits a thermal conductivity of 30-35 W/(m·K), significantly higher than that for traditional alumina fillers (~20 W/(m·K)). Such superior heat transfer capability stems from its highly ordered crystal structure and low lattice defects. Experimental evidence suggests thermal conductivity is enhanced by 15-20% when purity is increased from 99.5% to 99.9%, primarily through reduced phonon scattering due to fewer impurities.

Spherical morphology is also crucial to thermal performance. Spherical particles, in contrast to irregular alumina particles, provide improved stress distribution and improved packing density (theoretically 74%). The close packing minimizes interfacial thermal resistance between the filler and matrix and creates more efficient channels for heat transfer. Spherical alumina powder is observed by scanning electron microscopy (SEM) to have an extremely flat surface (Ra < 0.1 μm), which further enhances contact thermal resistance between particles.

Additionally, spherical alumina is an excellent electric insulator. It has a volume resistivity above 10¹⁴ Ω·cm and is chemically inert, making it ideally suited for electronic devices. Its coefficient of thermal expansion (7-8 × 10⁻⁶/°C) is near that of most encapsulant materials and reduces interfacial stress during thermal cycling.

Fig 2. Pt100 Temperature Sensors, image from realpars.com

In Pt100 temperature sensors, spherical alumina powder is primarily applied as a thermal conductive filler in the protective sheath or encapsulation layer. The functional mechanism of spherical alumina powder can be discussed based on optimization of heat conduction paths and homogenization of temperature fields.

The most crucial part of a Pt100 sensor is its platinum resistance element. Its measurement accuracy relies on the speed at which it establishes thermal equilibrium with the ambient medium. Conventional encapsulation materials possess poor thermal conductivity, leading to longer response times. With the inclusion of high-thermal-conductivity spherical alumina, the filler particles create a 3D network of heat conduction, significantly enhancing heat transfer efficiency.

Spherical alumina fillers help to dissipate local heat gradients to reduce temperature gradients across the sensor. This is necessary for measurement accuracy, as platinum resistance is very sensitive to local overheating.

The spherical, uniform shape of spherical alumina improves enhanced filler-matrix contact, lowering interfacial thermal resistance. Spherical particles exhibit ~30% enhanced interfacial bonding energy between polymer matrices over irregular particles, lowering phonon scattering losses. Moreover, their geometric symmetry preserves appropriate alignment during processing, obtaining homogeneous filler distribution.

The inertness of spherical alumina protects the platinum resistor from corrosive environments. Accelerated aging tests validate that Pt100 sensors containing spherical alumina fillers last 2-3 times longer under harsh environments (85°C, 85% RH) because of the filler's ability to block the diffusion of moisture.

Two of the most critical parameters in managing Pt100 sensor performance are spherical alumina powder particle size distribution and purity level. These parameters must be optimized by balancing thermal conduction performance and manufacturability.

There is optimum particle size range based on research. As powder size shifts from 1 μm to 10 μm, composite thermal conductivity rises initially, reaches a maximum at 3-5 μm, and then reduces. The causes thereof are:

Particle size spread width is also important. Although theoretically, monodisperse systems (size spread <10%) have the highest thermal conductivity, a moderate spread (15-20% spread) enhances packing density in practice. Laser diffraction measurement indicates that bimodal spreads (main peak at 3 μm and secondary peak at 0.7 μm) permit 65 vol% filler loading without excessive viscosities, minimizing step response time to less than 1.5 seconds.

Greater purity enhances perfection in crystal lattices. With increasing purity of alumina from 99.6% to 99.95%, the benefit of intrinsic thermal conductivity over greater cost of processing outweighs the effect. Significantly, even small impurities (e.g., Si, Na in 0.01% levels) exhibit strong phonon scattering effects. Mass spectrometry indicates that keeping Na below 5 ppm further increases composite thermal conductivity by 8-10%.

Purity also has an effect on interface stability. Spherical alumina of high purity has fewer surface hydroxyl groups, reducing the sensitivity of polymers to moisture. Damp heat cycling tests confirm that 99.95% purity fillers exhibit 30% less resistance drift when compared with 99.9% purity sensors due to reduced moisture absorption at interfaces.

High-thermal-conductivity spherical alumina powder considerably improves Pt100 temperature sensors by enhancing heat transfer paths and ensuring temperature uniformity. Future studies could look into surface treatment techniques to reduce interfacial resistance even further. Stanford Advanced Materials (SAM) specializes in spherical powders. Send us an inquiry for more information.

United States

.png)