Recently, we have received many customers inquiring about how to reduce alloy powder wastage in metal 3D printing. As a supplier of powder materials, we understand that quality metal powders are extremely costly. The effective powder management not only saves you production money but also increases efficiency as well as sustainability in printing. Therefore, we have compiled this guide to help you maximize every gram of powder and prevent unnecessary wastage.

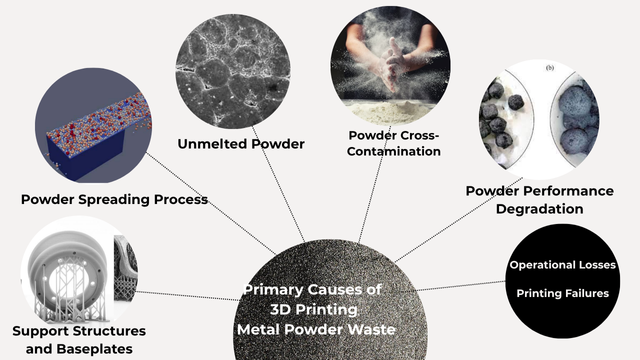

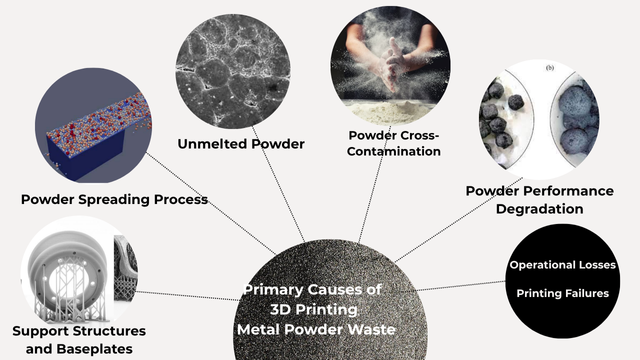

Primary Causes of 3D Printing Metal Powder Waste

- Support Structures and Baseplates: To serve as a protection against thermal stress deformation and assist in forming the part, support structures and baseplates must be printed. They are removed after printing, generating significant waste powder.

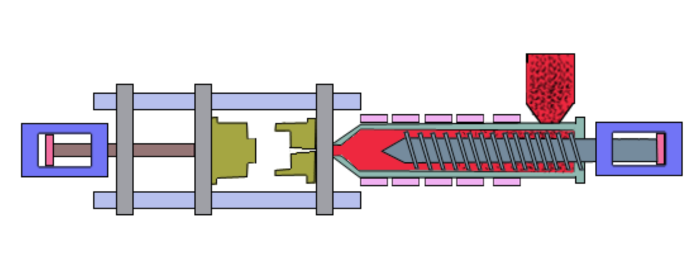

- Powder Spreading Process: Excess powder in every layer is pushed out of the working area by the scraper or roller into the overflow bins. Even though this powder is theoretically recyclable, there is a risk of contamination and loss of performance.

- Unmelted Powder: Powder in or at edges of the part contour which is not fully melted by the laser/electron beam.

- Powder Cross-Contamination: Cross-mixing of different material powders due to incomplete cleaning of equipment during changes in material or mishandling of recycled powder.

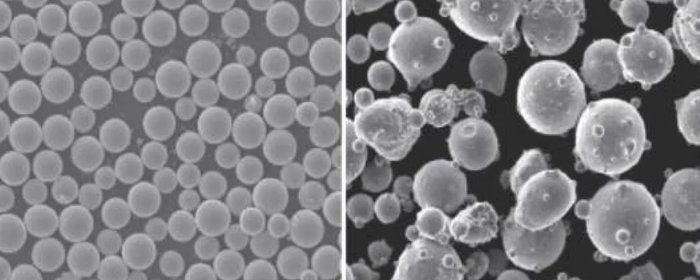

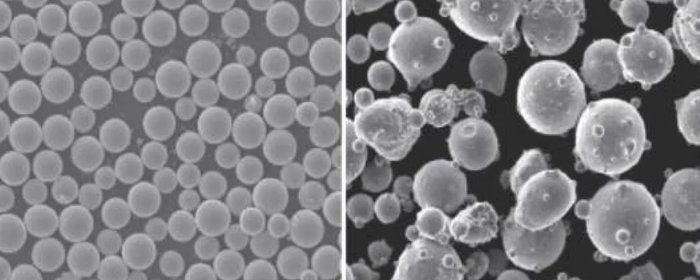

- Powder Performance Degradation: Repeated exposure to high temperatures, oxidation, and spreading via recycling degrades powder quality with reduced sphericity, more satellite particles, more oxygen content, reduced flowability, and eventual inability to be used.

- Operational Losses: Spillage or contamination due to mishandling while extracting powder, sieving, storing, or transporting.

- Printing Failures: Defects or scrap of parts caused by parameter errors, equipment failure, or software issues typically render the batch of powder unusable.

Key Strategies to Reduce Powder Waste

Based on the above analysis, we can see that powder quality, storage methods, and 3D printing operations all affect material utilization. Therefore, we can reduce alloy powder waste by improving these areas.

1. Minimize Support Structures through Printing Parameter Optimization

Problem: Too many support structures make post-processing difficult and squander additional powder.

Solutions:

- Make use of simulation software for design optimization, supports only where needed.

- Change print orientation to reduce overhangs and support requirements.

- Employ topology optimization or lattice structures to reduce material usage while preserving strength.

2. Powder Recycling and Sieving Procedures Need to Be Tightly Controlled

Problem: Improper handling of reuse powder can lead to printing defects or performance degradation.

Solutions:

- Graded Sieving. Make use of high-precision vibrating sieves to remove agglomerations and impurities, and achieve powder flowability.

- Monitoring Oxygen Content. For highly oxidation-susceptible materials like titanium and aluminum alloys, store powder and sieve in an inert gas atmosphere.

- Different materials contain different recycling constraints. For example, 316L stainless steel can be recycled 5–10 times and titanium alloys 3 times.

The table 1. summarizing oxidation-prone alloy powders in metal 3D printing:

|

Alloy Powder

|

Classic Products

|

Oxidation Risk

|

|

Titanium Alloys

|

Ti-6Al-4V, Ti-64

|

Very High

|

|

Aluminum Alloys

|

AlSi10Mg, Scalmalloy

|

High

|

|

Nickel-based Superalloys

|

Inconel 718, 625

|

Moderate

|

|

Copper Alloys

|

CuCrZr, GRCop

|

Moderate

|

|

Tantalum/ Tungsten

|

Ta2.5W, Ta10W

|

High

|

3. Use Efficient Powder Recovery Systems

Issue: Manual recovery methods cause powder dispersion or contamination.

Solutions:

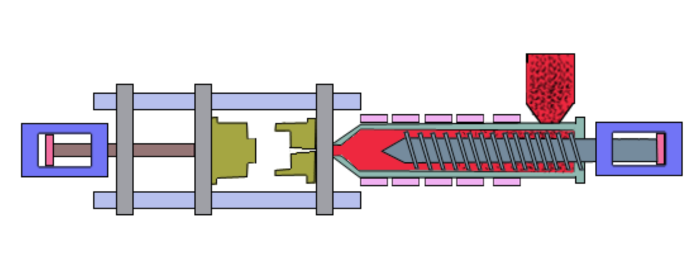

- Install enclosed automatic powder recovery systems (e.g., integral recycling modules in 3D printers) with low manual handling loss.

- Store unused powder in vacuum storage to prevent moisture pickup or oxidation.

4. Plan Print Batches Strategically to Reduce Material Changes

Issue: Too much material change causes residual waste and increased equipment cleaning time.

Solutions:

- Batch Printing: Print all parts of the same alloy before printing parts of other alloys to reduce material switches.

- Modular Powder Bins: Rapid powder bin exchange is available on some commercial printers for multi-material prints.

5. Print with High-Quality Powder to Reduce Print Failures

Problem: Low-quality powder will cause print failure leading to wastage, e.g., balling, cracking.

Solutions:

- Employ powders of high sphericity and flowability for well-spreading.

- Regulate particle size distribution, e.g. 15–53 μm for SLM, coarser for EBM.

- Collaborate with suppliers to optimize materials: Different composition in powder can improve print success rates.

Powder Conservation is a Systematic Effort

Reducing metal 3D printing waste saves money, as well as making the process more efficient and sustainable to produce. Design optimization, following stringent recycling process, effective equipment utilization, and selection of high-quality powders can significantly minimize material loss.

If you have additional questions regarding alloy powder selection, storage, or recycling, please don't hesitate to reach out to Stanford Advanced Materials (SAM) anytime.