Additive Manufacturing (AM) technology makes possible the integrated forming of complex structures, widely used in the aerospace, biomedical, and other fields. Powdered metal and alloy are the most important factors in determining the performance of printed parts. Ideal metal powders need to be highly spherical, have good flowability, low oxygen content, and excellent interfacial bonding properties. Regrettably, raw powders can become oxidized and create agglomerates when stored, transported, and printed. Luckily, powder performance can be improved by surface modification.

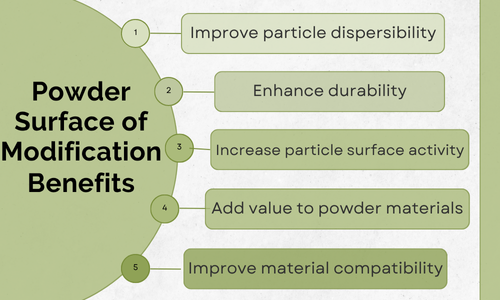

Fig 1. The benefits of powder surface modification

Through coating and oxidation treatment, the powder's flowability, oxidation resistance, and interfacial bonding properties can be significantly enhanced.

Particle Coating Technology is the uniform metallization of spherical metal powder particles by a thin, dense film to improve the physical, chemical, or functional properties.

Purpose

Coating Methods

Particle coating can be achieved through physical and chemical methods. Among physical methods, fluidized bed coating technology and dry mechanical coating are useful with metal powders.

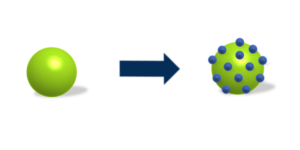

Fig 2. Fine particles adhere to larger core particles

Chemical coating methods include:

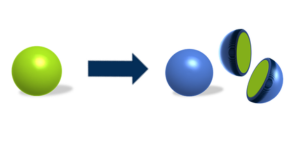

Fig 3. dense coating for powder surface modification

Nano-coating technology refers to preparing 1-100 nm thick films or modified layers on substrate surfaces to endow materials with special properties. Compared with traditional coatings, its core features include:

Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), Sol-Gel process, and electrochemical deposition are also methods for acquiring nano-coating technology. Atomic Layer Deposition (ALD) is, however, one of the most precise nano-coating preparation technologies available today.

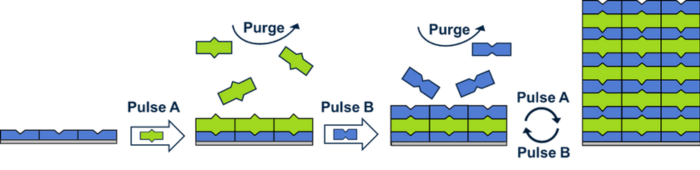

Atomic Layer Deposition is a thin-film process that deposits material onto a substrate surface layer by layer in the shape of single-atom films. Unlike conventional chemical vapor deposition, ALD divides the complete chemical reaction into multiple half-reactions, thereby offering single-atom-level thin-film control.

Fig 4. Atomic Layer Deposition Process for Powder Surface Modification

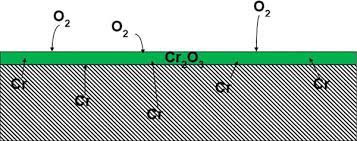

Controlled oxidation is a technology of partial surface oxidation of powders under certain conditions to form a nanoscale oxide layer. Controlled oxidation technology is widely used for titanium alloy and high-temperature alloy powders in order to improve their high-temperature stability.

Titanium powder easily oxidizes in the presence of air to form a TiO₂ layer. However, the nanoscale TiO₂ layer may be a passivation layer. Thin TiO₂ layer effectively covers up oxygen diffusion, reduces powder oxygen increment (O₂ wt%), and can be used to prevent powder failure due to over-oxidation. Similarly, chromium-based powder naturally forms a Cr₂O₃ layer with high passivation capability that protects the substrate.

Fig 5. Cr₂O₃ layer

Effects:

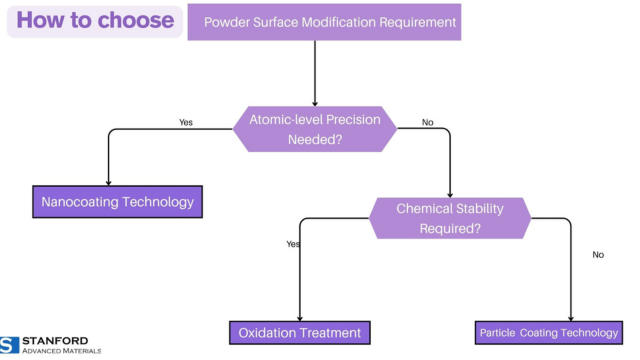

Now you've read this, you might ask: Don't the three processes all coat up the powder? How are they really any different? Well, although all three technologies form surface layers, they are in fact quite different mechanisms, principles, and objectives of application.

First, their core purposes differ.

|

Technology |

Core Objective |

Effect |

Application |

|

Particle Coating |

Macroscopic isolation protection |

Anti-oxidation, moisture resistance, improved flowability |

Conventional powder metallurgy, energy storage materials |

|

Oxidation |

Controlled passivation |

Forms stable oxide layers, balancing activity and protection |

Titanium alloy, high-temperature alloy powder |

|

Nano-coating |

Interface functionalization |

Precisely regulates surface physicochemical properties |

High-end AM, biomedical implants |

Second, their mechanisms differ essentially.

In terms of cost, nano-coating is the most expensive, followed by oxidation treatment, while particle coating technology is the most economical.

Based on the above comparison, their differences are clear. The selection is straightforward:

Stanford Advanced Materials (SAM) specializes in metal 3D printing materials. Send us an inquiry for more information.

United States

.png)