Rhenium is a rare, high-melting-point metal. It is irreplaceable in high-end fields such as aviation, aerospace, energy, and medical industries. Among these, rhenium alloys such as tungsten-rhenium, molybdenum-rhenium, nickel-rhenium and niobium-rhenium hold significant value in high-temperature applications.

What is the Rhenium Effect?

Only a small amount of rhenium needs to be added to tungsten, molybdenum, or chromium to increase the melting point by 300°C to 500°C. Not only that, but strength and plasticity are greatly enhanced. This phenomenon is referred to as the "Rhenium Effect."[1]

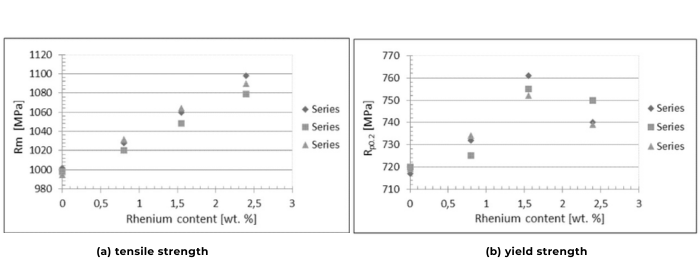

Kamil Majchrowicz[2] found that the incorporation of rhenium enhanced the corrosion resistance of the IN718 alloy on two exposed surfaces in 0.1 M Na₂SO₄ and NaCl solutions. Other researchers have also studied the microstructure and mechanical properties of tungsten alloys. The studies have found that the incorporation of rhenium affects the tensile strength and yield strength of tungsten, as Figure 1 below.[3]

Fig 1. (a) tensile strength, (b) yield strength

This incredible phenomenon cannot be dissociated from the outstanding characteristics of the rhenium element.

Rhenium has a very high melting point. Its melting point is 3186°C, second highest to tungsten (3422°C) and carbon (above 3500°C). However, rhenium is more oxidation-resistant than tungsten and can maintain structural stability above 2000°C.

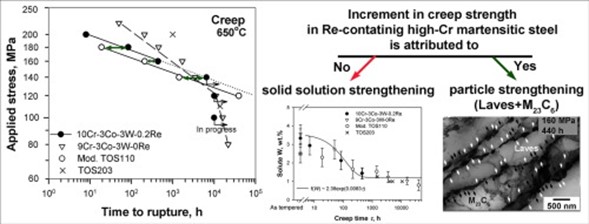

It also possesses outstanding creep resistance. Experiments have confirmed that the creep resistance of rhenium at 1000°C to 1500°C is considerably greater than that of tungsten, molybdenum, and nickel alloys. By the way, creep is the slow deformation of metals due to long-term stress at high temperatures, e.g., the elongation of turbine blades under high temperatures.

Fig 2. Rhenium in the experimental steel improved the short-term creep strength at 650 °C[4]

As noted earlier, rhenium can significantly enhance and improve the performance of alloys as an alloying agent. Indeed, rhenium is able to form a range of alloys with some metals like tungsten, molybdenum, nickel, niobium, platinum, thorium, iron, and copper. Of them, tungsten-rhenium, molybdenum-rhenium, nickel-rhenium, and niobium-rhenium alloys are the most significant high-temperature-resistant rhenium alloys with extensive applications in high-temperature parts.

Tungsten-Rhenium Alloys

Tungsten has the highest heat resistance, the highest melting point, the highest strength, and the lowest coefficient of thermal expansion among refractory metals. As such, tungsten-rhenium alloys, based on this, can generally enhance the superior properties of both tungsten and rhenium. It has a temperature for heat resistance as high as 3300°C. It is being used primarily as the key high-temperature-resistant material for jet engines.

Molybdenum-Rhenium Alloys

Molybdenum possesses a high melting point and excellent high-temperature strength, along with remarkable wear and corrosion resistance. Its rapid heat transfer capability and minimal thermal expansion make it ideal for extreme environments. When alloyed with 2-5% rhenium, molybdenum gains enhanced plasticity and strength. The room-temperature tensile strength, ductility, and resistivity all increase proportionally with rhenium content.

These alloys work in important places:

Niobium-Rhenium Alloys

Niobium acts much like tantalum. Steel makers use it most. Even small amounts of niobium help steel a lot.

Niobium makes steel:

Niobium itself handles heat well. It stands up to high temperatures. It's easy to work with. These traits make niobium-rhenium alloys valuable.

People use them for:

Nickel-Rhenium Alloys

Nickel is also a high-strength, high-melting-point metal. Nickel-rhenium alloys not only have high-temperature resistance, but they also have high strength and good ductility. Nickel-rhenium alloys are significant materials for modern aviation engines. This type of alloy is used to create turbine blades and combustion chambers for jet engines. They are used to manufacture exhaust nozzles of jet engines too, with better performance.

Rhenium alloys come in a variety of forms, such as blocks, plates, wires, and powders. The powder types can achieve complex structures beyond what other processing methods can achieve. So, when should you utilize rhenium alloy powder?

1. When Fabricating Complex Geometric Structures

Conventional casting or forging methods cannot achieve precise internal cavities, asymmetrical flow channels, or topology-optimized structures. While Rhenium alloy powders can be directly shaped with 3D printing. For example:

2. When Surface Strengthening or Repair is of Vital Importance

Rhenium alloy powders can create special coatings on materials like nickel-based alloys. These coatings resist high heat and oxidation when made with plasma or cold spraying. Some typical applications are

3. When Material Utilization Becomes a Vital Factor

Rhenium is a strategic resource, and conventional processing is in excess of 50% waste. Powder metallurgy processes can achieve utilization rates up to 95%. For example

Stanford Advanced Materials (SAM) offers a variety of rhenium alloy powders, such as tungsten-rhenium alloy powder and molybdenum-rhenium alloy powder.

The choice of the appropriate rhenium alloy depends on the specific high-temperature requirements and application conditions. As technology evolves and production techniques are refined, the possibilities for the application of rhenium alloys should grow, further solidifying their place in high-tech applications.

References:

What Are The Uses of Rhenium Powder

Spherical Tungsten Rhenium Alloy Powder: WRe25 vs WRe26 vs WRe5

[1] Huang, M., Zhu, J. An overview of rhenium effect in single-crystal superalloys. Rare Met. 35, 127–139 (2016). https://doi.org/10.1007/s12598-015-0597-z

[2] Majchrowicz, K., Pakieła, Z., Kamiński, J. et al. The Effect of Rhenium Addition on Microstructure and Corrosion Resistance of Inconel 718 Processed by Selective Laser Melting. Metall Mater Trans A 49, 6479–6489 (2018). https://doi.org/10.1007/s11661-018-4926-3

[3] Skoczylas P, Kaczorowski M. Preliminary Study of the Rhenium Addition on the Structure and Mechanical Properties of Tungsten Heavy Alloy. Materials (Basel). 2021 Nov 30;14(23):7365. doi: 10.3390/ma14237365. PMID: 34885520; PMCID: PMC8658680.

[4] A. Fedoseeva, I. Nikitin, N. Dudova, R. Kaibyshev, On effect of rhenium on mechanical properties of a high-Cr creep-resistant steel, Materials Letters, Volume 236, 2019, Pages 81-84, ISSN 0167-577X, https://doi.org/10.1016/j.matlet.2018.10.081.

United States

.png)