As representatives of refractory metals, tungsten (W) and rhenium (Re) can be combined to form tungsten-rhenium alloy powders. More specifically, an appropriate amount of rhenium can dissolve in tungsten to form a solid solution alloy powder. Based on appearance, W-Re powders are categorized into spherical and irregular forms. It's worth mentioning that as technology advances, the demand for spherical W-Re powders has been steadily increasing.

Spherical tungsten-rhenium alloy powder is made from tungsten (W) and rhenium (Re). Tungsten is known for its high melting point and resistance to extreme temperatures, while rhenium is a rare metal that offers high strength, corrosion resistance, and a high melting point. Combining these two metals provides unique properties such as better heat resistance, strong mechanical properties, and electrical conductivity.

In many cases, it can replace pure tungsten, tungsten-lanthanum, tungsten-cerium, or other doped tungsten materials as electrodes or filaments. Additionally, due to its excellent properties, it is used in high-temperature components, such as spacecraft nozzles, vacuum furnace heat shields, and more.

Fig 2. Tungsten Rhenium Alloy Thermocouple

WRe25, WRe26, and WRe5 are the most common tungsten-rhenium alloy powders. Though all made of tungsten and rhenium, they have significant differences.

The tungsten-rhenium alloy powders have different component ratios. Generally, W content ranges from 73.9% to 99.8%, and Re content ranges from 0.1% to 26%.

Table 1. Composition Comparison of WRe25, WRe26, and WRe5

|

|

rhenium |

tungsten |

|

WRe25 |

25% |

75% |

|

WRe26 |

26% |

74% |

|

WRe5 |

5% |

95% |

WRe26 and WRe25 have similar compositions, with WRe26 having slightly more rhenium. WRe5, with a much lower rhenium content, shows greater performance differences.

● WRe25 and WRe26: With higher rhenium content, these alloys show better creep resistance and mechanical strength at high temperatures. The addition of rhenium significantly enhances the alloy’s stability in extreme heat.

● WRe5: Due to its lower rhenium content, WRe5 performs well at high temperatures but has slightly weaker creep resistance compared to WRe25 and WRe26, making it more prone to deformation in extreme heat.

Thus, WRe25 and WRe26 have better high-temperature stability than WRe5, making them suitable for more extreme high-temperature environments.

● WRe25 and WRe26: Their high rhenium content boosts the alloy’s corrosion resistance, especially in high-temperature oxidizing environments, effectively preventing oxidation and corrosion.

● WRe5: Its corrosion resistance is slightly weaker than WRe25 and WRe26, particularly when exposed to corrosive atmospheres or oxidation for extended periods.

● WRe25 and WRe26: Higher rhenium content slightly reduces electrical and thermal conductivity, though both properties remain good. The increased rhenium enhances high-temperature stability but decreases conductivity slightly.

● WRe5: With lower rhenium content, WRe5 has higher electrical and thermal conductivity, making it suitable for high-temperature sensors and electronic devices requiring better conductivity.

Therefore, WRe5 has better electrical and thermal conductivity than WRe25 and WRe26, ideal for applications that require higher conductivity.

● WRe25 and WRe26: Higher rhenium content provides better ductility and toughness, especially at high temperatures. These two alloys also show superior tensile strength and ductility.

● WRe5: While it has good strength, WRe5’s lower rhenium content makes it less ductile than WRe25 and WRe26, especially in terms of high-temperature tensile strength.

Thus, WRe25 and WRe26 offer better mechanical strength and ductility in high-temperature environments, suitable for high-stress, high-temperature applications.

Table 2. Comparison of WRe25, WRe26, and WRe5 composition and properties

|

Properties |

WRe25 |

WRe26 |

WRe5 |

|

W Percentage |

75% |

74% |

95% |

|

Re Percentage |

25% |

26% |

5% |

|

High Temp Stability |

Excellent |

Excellent |

Good |

|

Creep Resistance |

Excellent |

Excellent |

Good |

|

Corrosion Resistance |

Excellent |

Excellent |

Good |

|

Electrical Conductivity |

Good |

Good |

Excellent |

|

Thermal Conductivity |

Good |

Good |

Excellent |

|

Strength at High Temp |

Excellent |

Excellent |

Good |

|

Ductility |

High |

Very High |

Moderate |

|

Main Applications |

High temp, aerospace |

Similar to WRe25 |

Electronics, sensors |

WRe25 and WRe26 have excellent performance in high-temperature, corrosion resistance, and creep resistance, suitable for extreme environments. WRe26 has slightly better performance due to its higher rhenium content, though the difference is minor.

WRe5 has a lower rhenium content, and its high-temperature performance is not as excellent as WRe25 and WRe26. However, its electrical and thermal conductivity are better, making it more suitable for applications with higher electrical conductivity requirements.

Stanford Advanced Materials (SAM) is committed to the research and development of spherical powder technology. We supply all kinds of 3D printing metal powders, refractory metal powders, titanium, aluminum, stainless steel, cobalt chrome, nickel, copper, and so on. Of course, it contains the spherical tungsten-rhenium alloy powders (WRe26, WRe10) mentioned above. If you have any interest in it, please Get A Quote.

Related articles:

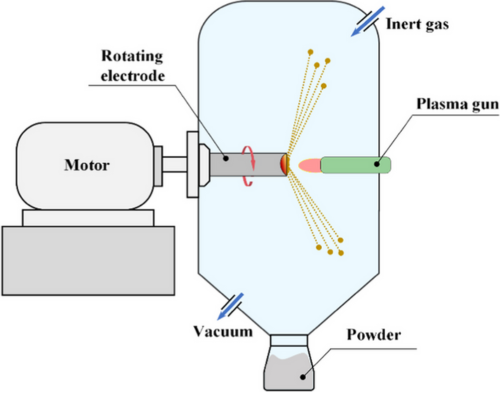

Plasma Rotating Electrode Process (PREP) and Plasma Atomization (PA): How to Choose

Titanium Grade 2 vs Grade 5: How Titanium Powders Are Classified

United States

.png)