In addition to the "twin" elements zirconium and hafnium, there are other elements that coexist in nature. For example, tantalum and niobium are often found together in the same minerals, typically in tantalite, niobite, and coltan. They share many similar properties and applications but also exhibit some notable differences.

Tantalum (Ta) is the third most refractory metal after tungsten and rhenium. Its corrosion resistance is comparable to that of glass, and it possesses excellent ductility. However, its hardness is relatively low; the Vickers hardness of pure tantalum after annealing is only 140 HV.

Niobium (Nb) is a silver-gray, soft, and ductile rare high-melting-point metal. It exhibits excellent superconductivity, high melting point, corrosion resistance, and wear resistance.

Niobium and tantalum both belong to Group 5 of the periodic table, and their atomic sizes are similar. As a result, they exhibit significant similarities in chemical properties.

Similarities:

Although tantalum (Ta) and niobium (Nb) share many similarities, they also have some notable differences. From Table 1, we can draw the following conclusions:

Additionally, although both niobium and tantalum are corrosion-resistant, tantalum exhibits higher corrosion resistance. Tantalum can resist the erosion of sulfuric acid and hydrofluoric acid.

Niobium exhibits significant superconductivity, while tantalum lacks this property. Niobium is the only metal with notable superconductivity at ambient pressure.

Table 1: Physical and Chemical Properties of Niobium and Tantalum

|

Property |

Niobium (Nb) |

Tantalum (Ta) |

|

Atomic number |

41 |

73 |

|

Atomic weight |

92.91 |

180.95 |

|

Atomic volume (cm³/g atom) |

10.8 |

10.9 |

|

Atomic radius (nm) |

0.146 |

0.147 |

|

Covalent radius (nm) |

0.134 |

0.134 |

|

Ionic radius [Å (6-coord)] |

0.69 (+5) |

0.69 (+5) |

|

Electron configuration |

[Kr] 4d⁴ 5s¹ |

[Xe] 4f¹⁴ 5d³ 6s² |

|

Electronegativity |

1.7 (+5) |

1.7 (+5) |

|

EK value |

13.60 (+5) |

13.60 (+5) |

|

Density (g/cm³) |

8.57 |

16.65 |

|

Melting point (°C) |

2477 |

3017 |

|

Boiling point (°C) |

4744 |

5458 |

|

Hardness (Mohs) |

6 |

6.5 |

|

Crustal abundance (×10⁻⁶) |

20 |

2 |

|

Valence |

3+, 5+ |

5+, (3+, 4+) |

|

Crystal structure |

Body-centered cubic |

Body-centered cubic |

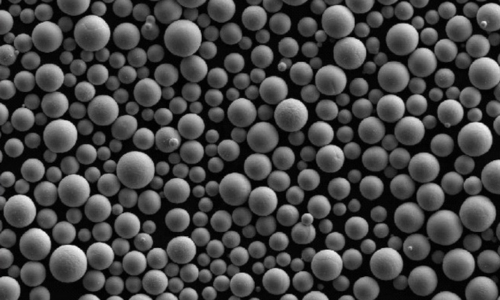

Let us briefly distinguish between the powdered forms of tantalum and niobium and their bulk counterparts. Although their forms have changed, their chemical properties remain the same because their atomic structures and electron configurations remain unchanged. However, since tantalum powder and niobium powder exist in powdered form, their physical properties and surface characteristics inevitably differ from those of bulk metals.

The main differences are as follows:

Tantalum powder and niobium powder share common applications in many fields, but they also exhibit significant differences in specific uses. Additionally, each has its own unique application areas.

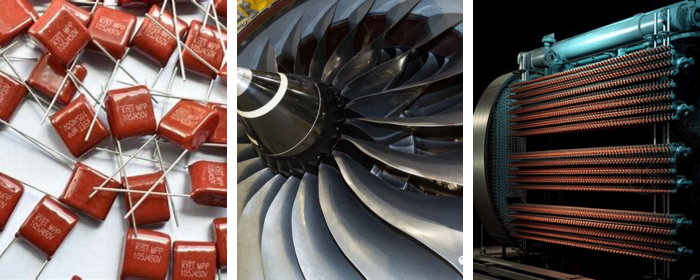

In the electronics industry, both are used to manufacture electrolytic capacitors. However, tantalum powder is primarily used for high-performance tantalum electrolytic capacitors, which are applied in high-end electronic devices such as smartphones, laptops, and medical equipment. Niobium powder, on the other hand, is used to produce lower-cost niobium electrolytic capacitors, mainly for mid- to low-end electronic devices.

In the field of high-temperature alloys, both tantalum powder and niobium powder are used to manufacture components for aircraft engines and rockets. However, tantalum powder is more commonly used for critical components in extreme high-temperature environments, while niobium powder is more often used as an additive in general high-temperature alloys.

In the manufacture of corrosion-resistant equipment, tantalum powder is widely used in chemical equipment such as reactors and heat exchangers due to its excellent resistance to strong acids and alkalis. Although niobium powder is also used in corrosion-resistant equipment, its corrosion resistance is slightly inferior to that of tantalum powder, limiting its application range.

In the field of superconducting materials, niobium powder dominates as the primary raw material for manufacturing low-temperature superconducting materials such as niobium-titanium and niobium-tin alloys. These materials are widely used in magnetic resonance imaging (MRI) and particle accelerators. Although tantalum powder is also used in superconducting materials, its application scale and importance are far less than those of niobium powder.

In the steel industry, niobium powder is widely added to steel as a microalloying element. The addition of niobium significantly improves the strength, toughness, and corrosion resistance of steel. In contrast, the application of tantalum powder in this field is very limited.

In the medical field, tantalum powder is widely used to manufacture orthopedic implants and dental restoration materials due to its excellent biocompatibility and corrosion resistance. Although niobium powder is also used in medical implants, its application scope and popularity are far less than those of tantalum powder.

Stanford Advanced Materials (SAM) provides Niobium Powder and Tantalum Powder of different particle sizes and purity.

|

Type |

Purity |

Shape |

Particle Size |

|

Ta Powder |

>99.9% |

Spherical |

50nm, 100nm, 1-45um, etc. |

|

Micro Ta Powder |

>99.9% |

Spherical |

1-10μm, 5-25μm, 15-45μm |

|

Nano Ta Powder |

>99.9% |

Spherical |

40-80nm; 30nm-1um (customized) |

|

Ta10W |

≥99.9% |

Non-Spherical |

-100 mesh |

|

Ta2.5W |

99.95% |

Non-Spherical |

-100 to 325 mesh |

|

Ta10W - Low Oxygen |

99.90% |

Non-Spherical |

-100 mesh |

|

Ferro Tantalum Powder |

|||

|

Tantalum Aluminide |

99.50% |

80 mesh |

|

Type |

Purity |

Shape |

Particle Size |

|

NB-1 |

99.90% |

Spherical |

1μm |

|

NB-2 |

99.90% |

Spherical |

10um |

|

NB-3 |

99.90% |

Spherical |

50nm |

|

FNb-1 |

99.50% |

150μm |

|

|

FNb-2 |

99% |

150μm |

|

|

FNb-3 |

98% |

180μm |

|

|

FeNb Powder |

≥99% |

-60 mesh ~ -200 mesh |

|

|

Niobium Titanium |

99.90% |

Spherical |

10~63μm, 63~105μm or customized |

|

Niobium Hafnium |

Spherical |

15-53μm, 53-180μm |

References:

Chemical Twins: Zirconium and Hafnium, the Similarities and Differences

United States

.png)