Thermal spraying is a surface enhancement technology with a wide range of industrial applications. It can form wear-resistant, corrosion-resistant, and high-temperature-resistant coatings on the surfaces of metals, ceramics, or composite materials. As a result, the performance of these devices and components is enhanced and their service life can be extended.

Thermal spray powders are crucial materials used in thermal spraying technology. The advantages of using spray powders include the fact that they are not limited by wire forming processes, have low production costs, and are widely available. Additionally, the components can be mixed in any proportion. Choosing the right thermal spray powder has a very obvious impact on the process effect.

Different types of powders have different characteristics and applicable fields. Therefore, when choosing a specific spray powder, you must first determine which type of powder can meet the application requirements. The following are the main types of thermal spray powders and their respective applicable industries.

• Nickel-based alloys: Inconel 625 and Inconel 718, suitable for high-temperature and corrosive environments, commonly used in turbine and aerospace engine components.

• Cobalt-based alloys: Such as the Stellite series, known for excellent wear and heat resistance, often used in valves, pumps, and cutting tools.

• Aluminum-based alloys: Lightweight and oxidation-resistant, commonly used for thermal barrier coatings and corrosion protection.

• Molybdenum and molybdenum-based alloys: Used for high-temperature and wear-resistant coatings, such as in automotive parts and industrial equipment.

• Alumina (Al2O3): Provides electrical insulation and wear resistance and is widely used in electronic components and mechanical parts.

• Zirconia (ZrO2): Known for excellent thermal shock resistance, often used for thermal barrier coatings, such as in gas turbines and aerospace engine components.

• Tungsten carbide (WC): Extremely hard and wear-resistant, widely used in cutting tools and wear-resistant parts.

• Tungsten carbide-cobalt (WC-Co): Combines the toughness of metals with the hardness of ceramics, used for wear-resistant coatings, such as in oil drilling equipment and mining machinery.

• Chromium carbide-nickel chromium (Cr3C2-NiCr): Used for high-temperature wear and corrosion-resistant coatings, such as in turbine blades and chemical equipment.

• Polyethylene (PE) and Polytetrafluoroethylene (PTFE): Used for corrosion-resistant and sliding coatings, such as in chemical containers and bearings.

• Composite powders: Combining metals and ceramics, such as nickel-aluminum/alumina composites, used for wear and oxidation-resistant coatings.

• Self-lubricating materials: Such as molybdenum disulfide (MoS2) or graphite, are used for friction-reducing and lubricating coatings, such as in bearings and sliding parts.

• Thermal barrier coating materials: Such as yttria-stabilized zirconia (YSZ), used in gas turbines and aerospace engines for thermal barrier coatings.

Physical properties of Powders are a key factor in determining thermal spraying process parameters. Therefore, when selecting thermal spray powders, it is important to carefully study the physical properties of the powders. Powders with the same composition can have significantly different effects on the thermal spraying process because of differences in physical properties. The main powder properties affecting the thermal spraying process include shape, particle size, particle size distribution, specific surface area, adsorption, and flowability.

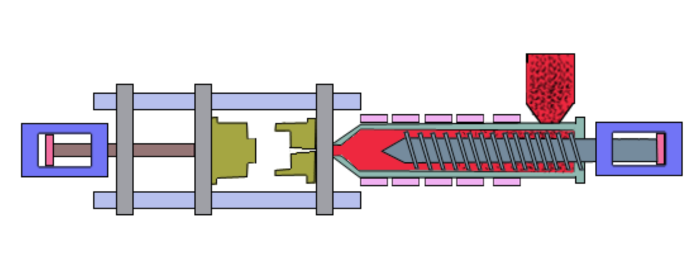

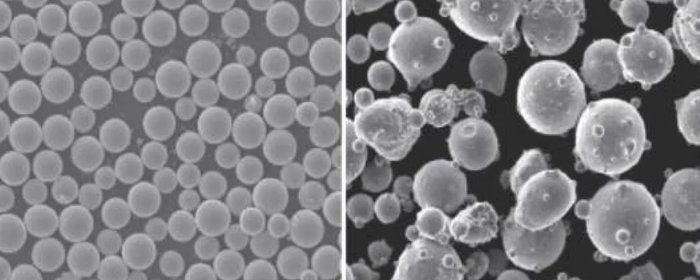

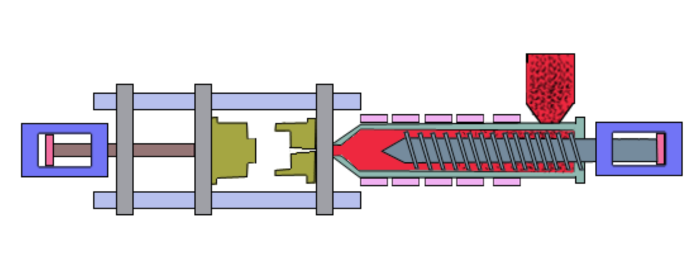

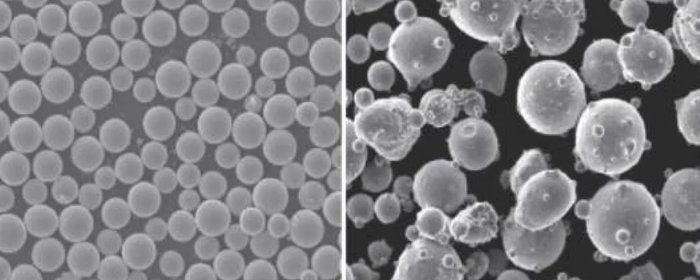

Thermal spray powders must have good flowability to be continuously, uniformly, and smoothly fed into the spray flame. Spherical powders undoubtedly have the best flowability. On the contrary, irregularly shaped powders have reduced flowability because of internal friction and "bridging" phenomena between particles.

Spherical powders have the smallest specific surface area and receive heat evenly, resulting in less oxidation and contamination by other impurities during the high-temperature spray process. Therefore, the shape of thermal spray powders is preferably spherical or spheroidal (nearly spherical).

.png)

Fig 1. Particle morphologies of alloy powder (a) spherical and (b) irregular in shape1

Particle size refers to the dimensions of the powder particles. The size of the particles directly affects powder delivery, heating conditions, and the density of the coating during thermal spraying.

The choice of particle size is closely related to the inherent properties of the material, such as melting point, thermal conductivity, specific heat capacity, and density, as well as the temperature of the heat source used in thermal spraying and the flight speed and dwell time of the particles in the spray flame. Generally, materials with high melting points, high densities, large specific heat capacities, and poor thermal conductivity should use finer powders for the same heat source, and vice versa.

For different heat sources, such as plasma spraying and flame spraying, the former's higher flame temperature and longer jet length allow for coarser powders compared to flame spraying. Similarly, water-stabilized plasma flames have higher temperatures and longer jets compared to gas-stabilized plasma flames, favoring the spraying of coarser powders.

.png)

Fig 2. Fine powder vs coarse powder mass flow rate results2

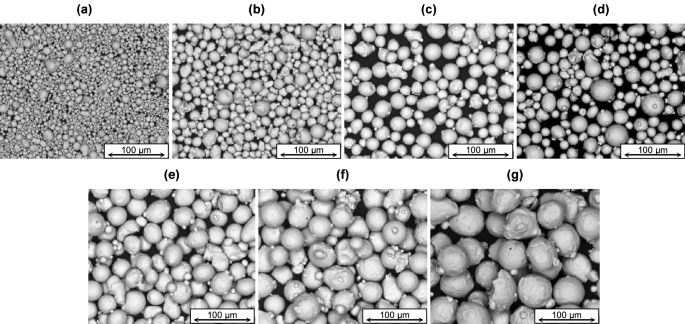

Particle size distribution refers to the ratio of different particle sizes in the powder. This parameter statistically represents the ratio distribution of particle sizes. A wider particle size distribution indicates a large difference in size between large and small particles. Using powders with a wide particle size distribution in the spray flame can result in finer particles melting first, while larger particles remain unmelted or incompletely melted, affecting the coating quality.

To achieve uniform and dense coatings, narrow particle size distribution powders should be selected. However, this increases the cost of powder materials. Additionally, coatings formed by spraying powders with uniform or similar particle sizes may have porosity between layers, reducing the coating density.

An ideal particle size distribution should meet the process requirements and coating performance needs. Incorporating a certain amount of finer powder with appropriately coarse particles can produce coatings where fine particles fill the gaps between coarse particles, resulting in a relatively dense coating.

Fig 3. Powders with different particle size distributions3

Flowability refers to the ability of the powder to flow and is a crucial indicator of the suitability of the powder for thermal spraying. It is typically measured using a Hall flowmeter, with units of seconds per 50 grams.

The physical significance is the time required for 50 grams of a specific powder to flow through a standard funnel with a defined aperture. The lower the flow time, the better the powder's flowability. Good flowability ensures uniform powder delivery, while poor flowability can cause clogging in the delivery channel.

Generally, alloy powders have better flowability, ranging from 20 to 45 seconds per 50 grams. Ceramic powders typically have poorer flowability, ranging from 50 to 120 seconds per 50 grams. Thermal spray powders should have good flowability to ensure smooth flow and uniform powder delivery in the delivery channel.

Spherical thermal spray powders, a new type of spray powder, not only have excellent flowability but also provide superior coating performance. However, poor sphericity, surface oxidation, and moisture absorption can reduce the flowability of the powder.

Stanford Advanced Materials (SAM) is a premium supplier of metal powders, providing high-quality spherical powders suitable for thermal spraying at very competitive prices. Powders including spherical Inconel 625 and spherical Inconel 718, Cobalt-based alloys, Aluminum-based alloys, and Molybdenum-based alloys are also available.

The selection of appropriate thermal spray powders, considering their shape, particle size, particle size distribution, and flowability, is critical to achieving high-quality coatings. Understanding these properties and their impact on the thermal spraying process enables industries to enhance the performance and lifespan of their components, ensuring reliability and efficiency in various applications.

Related Articles:

Spherical Powders Under the Microscope How Particle Shape Influences Functionality

Carbide Coating: A "Golden Shield" for Parts

1. Gülsoy, H & Gülsoy, Nagihan & Calışıcı, Rahmi. (2014). Particle morphology influence on mechanical and biocompatibility properties of injection molded Ti alloy powder. Bio-medical materials and engineering. 24. 1861-73. 10.3233/BME-140996.

2. Kroeger, Jens & Poirié, Thomas & Moghimian, Pouya & Marion, Frédéric & Larouche, Frederic. (2022). Flow rate ranges for spherical metallic powders for additive manufacturing. Progress in Additive Manufacturing. 7. 10.1007/s40964-021-00238-7.

3. Masaya Higashi, Naoya Kanno, Effect of initial powder particle size on the hot workability of powder metallurgy Ni-based superalloys, Materials & Design, Volume 194, 2020, 108926, ISSN 0264-1275, https://doi.org/10.1016/j.matdes.2020.108926.