Molybdenum Powder for Thermal Spraying

Stanford Advanced Materials (SAM) provides high quality molybdenum powder used for thermal spraying coatings.

Related products: Spherical Copper Powder for Thermal Spraying, Nickel Powder for Thermal Spraying, Titanium Spherical Powder for Thermal Spraying

Molybdenum Powder for Thermal Spraying

Stanford Advanced Materials (SAM) provides high quality molybdenum powder used for thermal spraying coatings.

Related products: Spherical Copper Powder for Thermal Spraying, Nickel Powder for Thermal Spraying, Titanium Spherical Powder for Thermal Spraying

Thermal spraying is a coating process where melted or heated materials are sprayed onto a surface. The materials of thermal spraying coatings are commonly in the forms of powder, wire or rod. They are heated and convert to micrometer-size particles. Then the particles are accelerated towards substrates and create a coating.

Molybdenum powder for thermal spraying is often used to manufacture engine pistons and synchronizer rings in the automotive industry because of its low friction coefficient, high sliding wear resistance and ductility. Coatings of molybdenum provide good frictional properties and scuff resistance as a result of an adherent, oxide surface layer that forms rapidly after spraying. The coatings are also hard and lubricious in nature, offering excellent dry-running properties.

Purity: ≥99.0%

Size and process:

-75 +38 µm; Agglomerated & Densified

-75 +30 µm; Sintered & Crushed

-45 +16 µm; Agglomerated & Sintered

Piston Rings: Molybdenum coatings on piston rings reduce wear and friction, enhancing engine performance and longevity.

Synchronizer Rings: Used in transmission systems, these rings benefit from molybdenum coatings for improved durability and smoother shifting.

Turbine Components: Molybdenum coatings are applied to various turbine parts to enhance wear resistance and high-temperature performance.

Landing Gear: Coatings provide corrosion and wear resistance, crucial for the longevity and reliability of landing gear components.

Extrusion Dies: Molybdenum coatings on extrusion die to improve their lifespan by reducing wear and maintaining dimensional stability.

Bearing Surfaces: Bearings coated with molybdenum exhibit reduced friction and enhanced wear resistance, improving operational efficiency.

Drilling Tools: Molybdenum coatings on drilling equipment improve resistance to wear and corrosion, extending the tools' operational life.

Our Thermal Spraying Molybdenum Powder is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

|

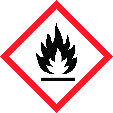

Signal Word |

Warning |

|

Hazard Statements |

H228 |

|

Hazard Codes |

N/A |

|

Precautionary Statements |

P210-P280-P240-P241-P370+P378 |

|

Flash Point |

Not applicable |

|

Risk Codes |

N/A |

|

Safety Statements |

N/A |

|

RTECS Number |

QA4680000 |

|

Transport Information |

UN 3089 4.1/PG 2 |

|

WGK Germany |

nwg |

|

GHS Pictograms |

|

Related articles:

Spherical Tantalum Carbide Powder in Thermal Spraying Applications