Stanford Advanced Materials (SAM) provides high quality nickel powder used for thermal spraying coatings.

Related products: Molybdenum Powder for Thermal Spraying, Spherical Copper Powder for Thermal Spraying, Titanium Spherical Powder for Thermal Spraying

Stanford Advanced Materials (SAM) provides high quality nickel powder used for thermal spraying coatings.

Related products: Molybdenum Powder for Thermal Spraying, Spherical Copper Powder for Thermal Spraying, Titanium Spherical Powder for Thermal Spraying

Thermal spraying is a coating process where melted or heated materials are sprayed onto a surface. The materials of thermal spraying coatings are commonly in forms of powder, wire or rod. They are heated and convert to micrometer-size particles. Then the particles are accelerated towards substrates and create a coating.

Nickel powder is extensively used in thermal spraying due to its excellent mechanical properties, corrosion resistance, and high-temperature stability. The pure nickel coatings are hard, dense and readily machinable.

Purity: ≥99.3%

Particle Size & Process:

-150 +45 µm, Precipitated

-75 +45 µm, Precipitated

Nickel powder for thermal spraying is typically used for:

-salvage and buildup of worn or mis-machined components made of nickel or nickel alloy parts

-replacement of Monel for corrosion applications when slightly higher hardness and machinability is needed

Aerospace

Automotive

Industrial Equipment

Oil and Gas

Our product is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

|

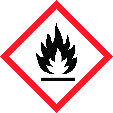

Signal Word |

Warning |

|

Hazard Statements |

H228 |

|

Hazard Codes |

N/A |

|

Precautionary Statements |

P210-P280-P240-P241-P370+P378 |

|

Flash Point |

Not applicable |

|

Risk Codes |

N/A |

|

Safety Statements |

N/A |

|

RTECS Number |

QA4680000 |

|

Transport Information |

UN 3089 4.1/PG 2 |

|

WGK Germany |

nwg |

|

GHS Pictograms |

|