Nitinol is a shape-memory alloy that scientists discovered by chance. However, its unique properties make it an essential material in medical devices and robotics. This article will introduce you to the basics and applications of Nitinol spherical powder.

Nitinol spherical powder is a spherical powder made from a nickel-titanium alloy. Nitinol is a metal alloy with unique properties, primarily composed of nickel and titanium, usually containing about 55% nickel and 45% titanium. This remarkable alloy can "remember" shapes or change shapes based on temperature.

The development of Nitinol was an accidental event. It was first developed in 1959 when scientists were working on creating a heat and corrosion-resistant alloy. During this process, they invented an alloy composed of 55% nickel and 45% titanium, known as Nitinol. The name "Nitinol" comes from its composition (Nickel and Titanium) and the Naval Ordnance Laboratory, where it was invented.

Initially, scientists formulated and used Nitinol as a corrosion-resistant alloy. Over time, they discovered its unique properties.

By heating, Nitinol can return to its original preset shape after deformation. This effect is caused by Nitinol's crystal structure changes, specifically involving two-phase transformations: the martensite and austenite phases.

Martensite Phase (Low-Temperature Phase):

• When Nitinol cools below a certain temperature, it transforms into the martensite phase, a crystal structure with lower symmetry. In this phase, the metal feels like rubber and is easily bendable.

• Nitinol can be mechanically deformed in the martensite phase, but this deformation is reversible, meaning the material can revert to its preset shape upon reheating to the austenite phase.

Austenite Phase (High-Temperature Phase):

• At higher temperatures, Nitinol is in the austenite phase, a crystal structure with high symmetry. In this phase, the metal achieves maximum rigidity and behaves like a spring when bent.

• In this state, the material's shape is preset or "remembered."

.png)

Fig 1. Crystal structure changes of Nitinol

Nitinol's superelasticity, sometimes referred to as pseudo-elasticity, allows the material to return to its original shape after experiencing significant strain. This recovery ability is highly noticeable within a specific temperature range and is closely related to its unique crystal structure and phase transformation behavior.

Mechanism of Superelasticity:

• At higher temperatures, Nitinol is in the austenite phase with a highly symmetrical crystal structure.

• When subjected to mechanical stress, Nitinol undergoes a phase transformation from austenite to martensite. This transformation enables the material to withstand significant strain.

• Upon the removal of stress, the material returns to its original austenite phase and shape. This recovery process is both rapid and complete.

Characteristics of Superelasticity:

• Nickel-titanium alloy can endure strains of 8% to 10% in its superelastic state and fully recover upon unloading, which is far superior to ordinary metals.

• Loading and unloading within the superelastic range leave no residual deformation.

• Nitinol's superelastic performance depends on temperature, being most notable at room temperature and slightly above.

In addition to shape memory and superelasticity, Nitinol possesses biocompatibility and high strength with corrosion resistance, making it a crucial material for various applications.

Nickel Titanium alloy spherical powder, with its unique shape-memory effect and superelastic properties, finds extensive applications in various high-tech fields:

Nitinol spherical powder can be used in metal injection molding to create small, complex-shaped components.

• Medical Devices: Minimally invasive surgical tools, orthodontic devices, orthopedic implants requiring complex geometries and high precision.

• Electronic Components: Micro-connectors and micro-mechanical systems need precise and miniaturized metal parts.

Fig 1. Orthopedic implants

Suitable for selective laser melting (SLM) and electron beam melting (EBM) technologies, allowing the production of complex, customized components. Reference: Process Selection of Additive Manufacturing for Metal Powder

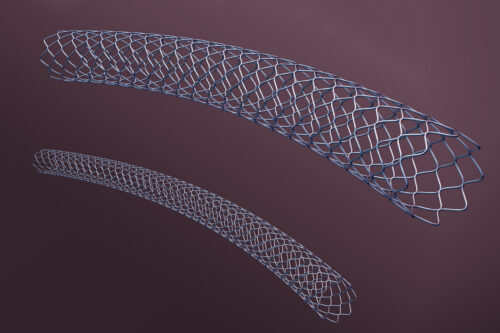

• Medical Field: Personalized medical implants such as artificial joints, dental implants, and custom stents.

• Aerospace: Lightweight, high-strength structural components like turbine blades, and engine parts.

• Automotive Industry: High-performance parts and sensors, including engine components, and suspension system parts.

Nitinol spherical powder can be used in thermal spraying techniques to form coatings with shape memory and superelastic properties. It can be used in the following industries.

• Aerospace and Energy: Coatings for turbine blades and other high-temperature components.

• Medical Equipment: Coatings for catheters, needles, and other medical tools.

Nitinol spherical powder is used in laser welding and repair of high-performance components, especially those requiring shape memory and superelastic properties. It can be applied in the following industries.

• Aerospace: Repair and joining of high-stress parts like engine components, wing structures, and landing gear.

• Medical Devices: Manufacture and repair complex implants and tools. For example: cardiac stents, orthopedic plates, and minimally invasive surgical instruments.

Fig 2. Nitinol cardiac stents

Because of its high surface area and chemical stability, Nitinol spherical powder has potential applications in catalysis and chemical reactions. It can be applied in the following industries.

• Catalyst Carriers: Serving as catalyst carriers in specific chemical reactions, such as environmental catalysis, fuel cells, and chemical synthesis.

• Chemical Sensors: Used in sensors to detect specific chemical substances, For example: gas sensors and biochemical sensors, offering high sensitivity and selectivity.

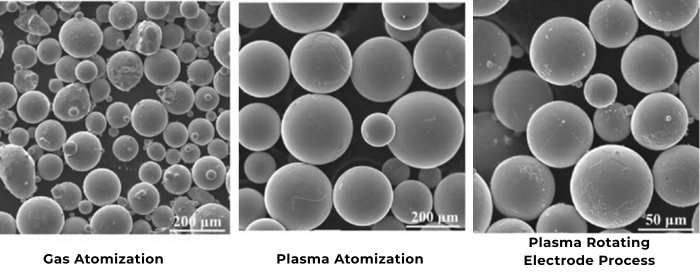

Stanford Advanced Materials (SAM) is a premium supplier of metal powders. SAM’s Nickel Titanium (Nitinol) Alloy Powder (NiTi) powders feature:

• Controlled composition

• High sphericity

• Good flowability

• Low oxygen content

• Fewer satellite particles

• Dense internal particle structure

If you are looking for high-quality Nitinol Spherical Powder, please contact us or check out our pages.

The shape-memory effect, superelasticity, biocompatibility, and corrosion resistance of Nitinol spherical powders make them a valuable material in medical and other fields. As technology advances, the applications of NiTi alloys are likely to expand, driving innovation and improving outcomes in these critical areas.