Zirconium dioxide powder is a versatile material used in various industries including electronics, biomedical applications, refractory materials, ceramics, etc. In this article, we will discuss the preparation methods, extensive applications, and safety concerns associated with zirconium dioxide powder.

Zirconium dioxide powder (ZrO₂) is a white inorganic compound composed mainly of zirconium and oxygen. It has a high melting point of around 2700°C, making it suitable for high-temperature applications. Its hardness is comparable to corundum and diamond, and it exhibits high strength and toughness, which makes it popular in mechanical applications.

Chemically, it has excellent corrosion resistance, being inert to acids, alkalis, and other chemicals. Additionally, ZrO₂ has good insulating properties and transparency, leading to its use in electrical and optical fields.

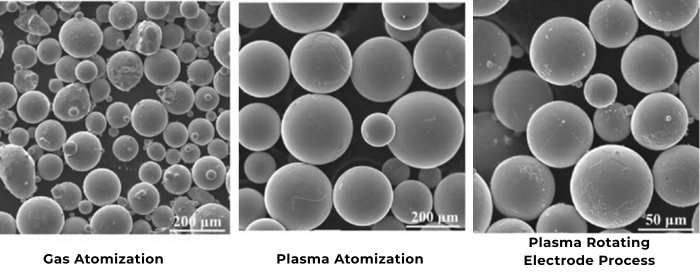

Fig 1. zirconium oxide powder

Zirconium dioxide (ZrO2), which occurs naturally in badeleyite, can also be chemically extracted from zircon. Currently, several processes are used to produce ZrO₂ powder:

1. Chemical Precipitation Method:

In this method, zirconium ions are chemically released from a zirconium salt solution to form zirconium dioxide powder.

l Zirconium Salt Dispersion: Zirconium salts (such as zirconium nitrate or zirconium chloride) are dissolved in water.

l Precipitation: Add a basic solvent (such as ammonia) to the zirconium salt solution, so that the zirconium ions precipitate as zirconium hydroxide.

l Heating: Zirconium hydroxide precipitate can be removed, washed, dried, and then heated at high temperatures to obtain zirconium dioxide powder.

2. Sol-Gel Method:

This method produces a sol, followed by gelation, followed by drying and calcination to form a zirconium dioxide powder.

l Preparation of sols: Zirconium salts are dissolved in solvent and hydrolysis and stabilizers are added to form sols.

l Gelation: Sol converts to gel with time.

l Drying and calcination: The gel is dried and calcined at high temperature to form ZrO₂ powder.

3. Hydrothermal Method:

This method involves a hydrothermal reaction at high temperature and pressure, yielding zirconium dioxide powder.

l Preparation of reaction solution: Mix the zirconium salt solution with a suitable mineralizer.

l Hydrothermal reaction: ZrO₂ is produced by heating the solvent under high pressure.

l Washing and drying: Wash, filter, and dry the resulting zirconium dioxide powder.

4. Oxidation Method:

This method involves direct oxidation of zirconium metal or zirconium alloys to form zirconium dioxide.

l Oxidation reaction: Heat zirconium metal or zirconium alloy with oxygen at high temperatures to form zirconium dioxide.

5. Vapor Deposition Method:

This method requires vapor phase reactions to deposit zirconium dioxide films or powders.

l Gas activation: Use a precursor gas containing zirconium (such as zirconium tetrachloride).

l Precipitation: By decomposing the reacting gas at high temperatures and depositing zirconium dioxide.

6. Electrolytic Method:

This method involves the electrolysis of zirconium salt solutions to produce zirconium dioxide.

l Electrolysis Reaction: Electrolyze zirconium salt solution in an electrolytic cell to produce zirconium dioxide precipitate.

l Washing and Drying: Wash, filter, and dry the precipitate.

Zirconium dioxide powder (ZrO₂) is widely used in various fields due to its excellent physical, chemical, mechanical, electrical, and optical properties, covering a range from everyday consumer products to high-tech industries. Below, we will explore the five most common uses.

Zirconia powder is widely used in the dental industry for dental crowns, bridges, implants, and other dental devices. Why is this subject interesting to dentists and patients? Because zirconium dioxide powder offers many benefits.

Fig 2. zirconia dental crowns

Benefits of zirconia dentures:

l Beauty: Its tooth-like color and transparency make it an excellent choice for natural-looking teeth.

l Biocompatibility: Zirconia is biocompatible, which means it is non-toxic and does not cause side effects when it comes into contact with human tissue.

l Durability: It has high crushing strength and strength, providing durability and durability under the mechanical stresses of chewing.

Zirconium dioxide powder is used for advanced ceramics. These ceramics are used in a variety of industrial applications, including thermal limiting, ceramic knives, and corrosion-resistant parts. Among them, ceramic cutting tools are the most common in our daily lives.

Zirconium oxide powder can be processed into various cutting tools. Compared with traditional cutting tools, knives made of zirconium oxide have unique advantages, such as no rust, health, and wear resistance.

Reasons why zirconium dioxide knives are superior to traditional tools:

l Durability and resistance: Zirconia's exceptional durability and corrosion resistance make it ideal for cutting tools and composites.

l Heat stability: Zirconia can withstand extreme temperatures without degradation, making it suitable for high-temperature environments.

l Fracture toughness: Its fracture toughness can be improved by controlling particles, whiskers, phase transformation, microcracks, and various hardening mechanisms during manufacturing.

Fig 3. ceramic knife made by Zirconia

Zirconia powder is a key material in the production of solid oxide fuel cells, which are used for efficient energy generation. It is the most widely used material in SOFCs due to its excellent power generation performance.

Advantages of Zirconia in Power Generation:

l High Ionic Conductivity: Cubic stabilized ZrO₂-based electrolytes have high ionic conductivity, maintain chemical stability at high temperatures, and exhibit pure oxygen ion conductivity across a wide range of oxygen partial pressures.

l Ideal Electrolyte Material: Zirconia powder, used as an electrolyte in SOFCs, facilitates oxygen ion movement while maintaining electrical insulation.

l High Efficiency and Low Emissions: SOFCs using zirconia can operate at high temperatures, achieving higher efficiency and lower emissions compared to traditional power generation methods.

Zirconium dioxide powder is used to produce refractory materials that line furnaces, kilns, and reactors in industries such as steel, glass, and ceramics. It is because of zirconia's excellent properties:

Properties of Zirconia for Refractories:

l High Melting Point: With a melting point above 2700°C, zirconia can withstand the extreme temperatures encountered in industrial processes.

l Chemical Inertness: It resists chemical attack from molten metals, slags, and glasses, ensuring the longevity and reliability of refractory linings.

l Mechanical Strength: Zirconia refractories maintain strength at high temperatures, providing structural support to industrial equipment.

Beyond dental applications, zirconium dioxide is used in orthopedic implants, such as hip and knee replacements.

Advantages of Zirconia in Implants:

l Biocompatibility: Similar to its dental applications, zirconia's biocompatibility ensures it is well-tolerated by the human body.

l High Wear Resistance: In joint replacements, wear resistance is crucial to minimize debris and prolong the implant's lifespan.

l Corrosion Resistance: Zirconia does not corrode in the body’s biological environment, ensuring that the implants remain stable and functional over time.

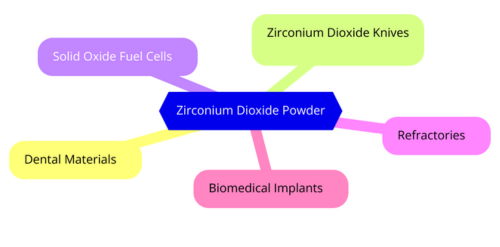

Fig 4. Top 5 uses of Zirconium Dioxide Powder

Given its wide range of applications, from everyday consumer products to high-tech industries, it is essential to understand the safety of ZrO₂ powder.

Zirconium dioxide is highly biocompatible, which is why it is widely used in dental materials and bone implants. This means that it is safe for therapeutic use and has low biological activity or toxicity.

Natural zirconium minerals generally contain trace amounts of radioactive elements (such as uranium and thorium). However, optimized and purified zirconium dioxide powder contains these radioactive components at very low, negligible levels. Thus, ZrO₂ powder used in industrial and medical applications is considered non-radioactive, posing no radioactive hazard to humans or the environment.

Stanford Advanced Materials (SAM) is at the forefront of powder development and offers various types of Zirconium Powders such as Micro Zirconium Powder and Nano Zirconium Powder. To learn more about these powders, please feel free to contact us and check out our pages.

Zirconium dioxide powder is a versatile material with remarkable properties that make it invaluable across various industries. Its high melting point, hardness, strength, and corrosion resistance enable its use in high-temperature and mechanical applications. Furthermore, its biocompatibility and non-radioactive nature ensure safety in medical and dental applications. As technology advances, the demand for high-performance materials like zirconium dioxide powder will continue to grow, further expanding its applications and benefits.