Nickel-based alloy powders are a common material for metal 3D printing, with a nickel content exceeding 30%. Nickel has a very high melting point (1453°C) and forms a dense, stable oxide layer at high temperatures. As a result, nickel-based alloys can maintain high strength and good corrosion resistance even at 650-1000°C. Depending on the added elements, nickel-based alloy powders are mainly divided into five categories, each with distinct properties and applications.

Why discuss Inconel and Incoloy together?

Because their compositions are similar—both contain nickel (Ni), chromium (Cr), and iron (Fe). Tables 1 and 2 list the typical compositions of Inconel and Incoloy alloys, respectively. By comparing them, we can see:

Table 1. Inconel composition

|

Element |

Inconel 725 |

Inconel 750 |

||||

|

Ni |

≥72.0 |

≥58.0 |

50.0–55.0 |

55.0–59.0 |

Bal. |

≥70.0 |

|

Cr |

14.0–17.0 |

20.0–23.0 |

17.0–21.0 |

19.0–22.5 |

18.0–21.0 |

14.0–17.0 |

|

Fe |

6.0–10.0 |

≤5.0 |

Bal. |

≤15.0 |

≤2.0 |

5.0–9.0 |

|

Mo |

– |

8.0–10.0 |

2.8–3.3 |

7.0–9.5 |

1.5–2.5 |

– |

|

Nb |

– |

3.15–4.15 |

4.75–5.5 |

2.75–4.0 |

0.6–1.2 |

0.7–1.2 |

|

Ti |

≤0.5 |

≤0.4 |

0.65–1.15 |

1.0–1.7 |

2.4–3.0 |

2.25–2.75 |

|

Al |

≤0.3 |

≤0.4 |

0.2–0.8 |

0.35–0.75 |

3.0–4.0 |

0.4–1.0 |

|

Co |

– |

≤1.0 |

≤1.0 |

– |

8.0–10.0 |

– |

|

Cu |

≤0.5 |

≤0.07 |

≤0.3 |

– |

≤0.5 |

≤0.5 |

Table 2. Incoloy composition

|

Element |

Incoloy 800 |

Incoloy 825 |

Incoloy 840 |

|

Ni |

30.0–35.0 |

38.0–46.0 |

19.0–23.0 |

|

Fe |

39.5–46.0 |

22.0–37.0 |

54.0–62.0 |

|

Cr |

19.0–23.0 |

19.5–23.5 |

19.0–23.0 |

|

Mo |

– |

2.5–3.5 |

– |

|

Cu |

≤0.75 |

1.5–3.0 |

– |

|

Ti |

0.15–0.6 |

0.6–1.2 |

– |

|

Al |

0.15–0.6 |

≤0.2 |

– |

|

C |

≤0.10 |

≤0.05 |

0.05–0.10 |

|

Mn |

≤1.50 |

≤1.0 |

≤1.0 |

Inconel stays stable in extreme high temperatures because it contains a high amount of nickel and little iron. It has good resistance to oxidation and creep. That's why Inconel alloys are used for aerospace parts like turbine blades and engine casings. For instance, GE's fuel nozzles are 3D printed from Inconel 718 alloy powder. Inconel alloys tend to resist corrosive media generally better. Inconel 625 performs particularly well in extremely corrosive conditions such as marine and chemical processing.

Fig 1. GE's fuel nozzle 3D printed with Inconel 718 alloy powder

Read more: 3D Printing Inconel 718 vs 625, What are the Differences

Incoloy powders are not as able to sustain high temperatures as Inconel but, with more chromium and copper, have good corrosion and heat resistance. Incoloy is suitable for medium to high temperature applications, typically 600°C to 1000°C. It is preferably applied in moderately corrosive situations, such as chemical process gear and heat exchangers. Incoloy 825, for instance, is acid-resistant due to its molybdenum (Mo) and copper (Cu) content.

Monel alloy powder is a nickel-based Ni-Cu solid solution. Nickel and copper can mix in any ratio. With high nickel content, Monel stays as a single-phase austenitic structure across a wide temperature range. It keeps good toughness even at liquid hydrogen temperatures. Copper is the main alloying element, boosting both corrosion resistance and electrical conductivity.

Monel was widely used in construction and household items in the past. Since the 1950s, cheaper stainless steel has replaced it in many areas. However, Monel still appears in marine and aerospace applications. For example, Monel K-500 used in ship pump shafts and seawater pipes shows an annual corrosion rate below 0.03mm. Still, nickel-copper alloy powder costs more than 316L stainless steel or Inconel 625, with limited market supply.

Most Hastelloy powders are nickel-chromium-molybdenum alloys. These high-performance materials combine nickel (Ni) with molybdenum (Mo), chromium (Cr), tungsten (W), and iron (Fe). Popular grades like C-276 (Ni-16Mo-16Cr-4W) and B-3 (Ni-28.5Mo-1.5Cr) target extreme corrosion environments. Nickel resists reducing media, molybdenum fights non-oxidizing acids (e.g., hydrochloric acid), while chromium adds oxidation resistance. Tungsten further improves pitting resistance.

Hastelloy powders excel in corrosion resistance and high-temperature strength. They perform well in wet oxygen, sulfurous acid, acetic acid, formic acid, and strongly oxidizing salts. This makes them popular in the chemical industry.

Nitinol is made with nearly equal atomic ratios of nickel and titanium. Its titanium content is much higher than other elements in nickel-based alloys. Nitinol is unique because it "remembers" its original shape when heated—this is called the shape memory effect. At certain temperatures, it can also stretch significantly without permanent deformation (superelasticity).

Read more: Nitinol Spherical Powder: A Superelastic Shape-memory Alloy

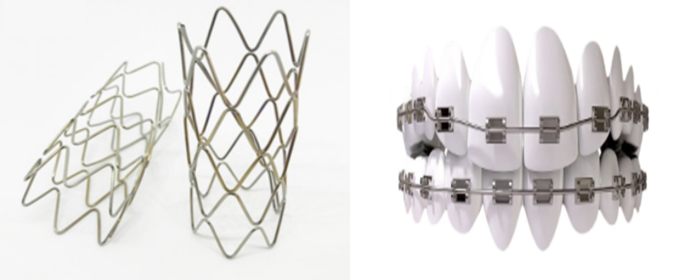

These traits make Nitinol ideal for medical uses. It's used in self-expanding stents, like cardiovascular and tracheal stents. Compressed during minimally invasive surgery, body heat makes Nitinol expand to fit blood vessels or tissues, reducing surgical trauma. Dentists also use it for orthodontic wires. At body temperature, it gently applies continuous force, easing tooth movement pain and follow-up visits.

Fig 3. Nitinol Arterial Stents and Orthodontic Wires

Though different from traditional bulk materials, Nitinol powder can be adapted for medical applications via 3D printing or powder metallurgy. Examples include customized bone repair scaffolds and porous artificial bones. It also works as coatings for minimally invasive tools.

Nickel-based alloy powders fall into five types: Inconel, Incoloy, Monel, Hastelloy, and Nitinol. They serve critical roles in high-temperature and corrosive environments, like aerospace, energy, and marine engineering. In powder form, Inconel and Hastelloy are top choices for 3D printing.

Stanford Advanced Materials (SAM) supplies spherical powders of Inconel, Incoloy, Monel, Hastelloy, and Nitinol. For more information, please contact our sales team: Get A Quote.

United States

.png)