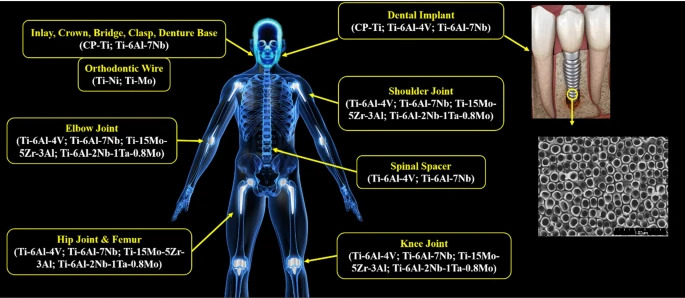

Definitely, titanium and titanium alloys are the material of choice for biomedical devices. Their applications in medicine are numerous, ranging from joint and bone implants to craniomaxillofacial and dental implants, surgical instruments, and external and internal prosthetic devices, as illustrated in Figure 1. So, why titanium is the top choice for medical implants?

Figure 1. Titanium alloys used in medical devices throughout the human body[1]

Titanium possesses several functional characteristics that are particularly advantageous for various biomedical uses.

1. Excellent Biocompatibility and Resistance to Corrosion

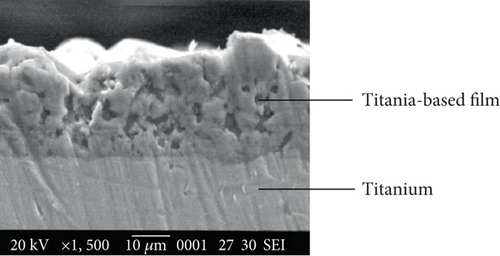

Titanium can possess a protective oxide film (TiO₂) developed spontaneously, even in trace amounts of oxygen. This oxide film is chemically impermeable, strongly adhesive, insoluble, and resistant to chemical reactions between human tissue and titanium. Hence, titanium alloy hip replacements and dental implants are compatible for decades of survival within the body without causing inflammation.

Fig 2. The excellent performance of titanium alloy is mainly due to the oxide film.[2]

2. High Strength-to-Weight Ratio

Among all the metals suitable for biomedical applications, the strength-to-weight ratio is the greatest for titanium. Titanium weighs approximately 56% less than stainless steel but has twice the yield strength and is very close to 25% more ultimate tensile strength.

3. Mechanical Properties Similar to Bone

The elastic modulus and coefficient of thermal expansion of titanium are significantly comparable to those of bone in humans. This significantly reduces the risk of stress shielding in the patient with a titanium implant as the load is distributed more homogeneously throughout the bone structure.

4. Non-Magnetic Properties

Titanium alloys are non-magnetic, as they cannot get magnetically charged easily. This provides several benefits to patients with titanium implants:

The widespread use of titanium alloys in medical devices is not only due to their unique advantages but also the result of rational comparisons with other materials.

Before the acceptance of titanium for biomedical applications, 316L stainless steel (18Cr-14Ni-2.5Mo wt%) was employed for implants. However, stainless steel easily suffers from pitting corrosion and will release poisonous alloy elements like nickel (Ni). Although cobalt-chromium alloys are more corrosion-resistant than 316L stainless steel when exposed to body fluids, toxic ions such as chromium and cobalt can still be released due to wear and corrosion. Magnesium alloys are lightweight but have lower mechanical strength and corrosion resistance. Precious metals like gold (Au), silver (Ag), platinum (Pt), and tantalum (Ta) are expensive, and thus their widespread use is restricted.

In comparison, titanium and titanium alloys have higher specific strength, lower toxicity, superior corrosion resistance, and lower cost. In addition, titanium alloys have a stronger bone bonding compared to stainless steel and cobalt-chromium alloys, with even more promising prospects for medical applications.

3D printing is revolutionizing the application of titanium and its alloys in biomedicine by providing unprecedented design freedom and functional innovation for medical implants. 3D printing enables the fabrication of complex structures that cannot be realized with traditional methods, including biomimetic porous scaffolds and anatomical implants with patient-specific tailored geometry. 3D printing not only solves the challenge of titanium alloy machining but also enhances the biocompatibility and mechanical advantages of titanium alloys to the utmost.

The properties of additively manufactured implants are, to a large extent, dependent on the properties of titanium and titanium alloy powders. The following titanium and titanium alloy powders are recommended for 3D-printed medical devices:

Stanford Advanced Materials (SAM) provides high-quality titanium alloy powders. Samples are available—Get A Quote.

Relative to other biomaterials used in medical implants, pure Ti and titanium alloys are primarily used since they possess good biocompatibility, fatigue life, corrosion resistance, and reduced Young's modulus. Recent advances in additive manufacturing (AM) technology have facilitated patient-specific organs and tissues to be exactly copied, along with complex porous microstructures, further enhancing the application of titanium and other biomaterials.

1. Why is titanium good for medical implants?

Titanium alloy powder (e.g., Ti-6Al-4V) offers high strength, low elastic modulus, high biocompatibility, and corrosion resistance, ideally suited for long-term orthopedic, dental, and cardiovascular implants.

2. What are the advantages of titanium alloy implants produced by 3D printing?

Customization, porous structure, and material efficiency.

3. In what ways do titanium alloy powder implants improve bone integration?

Surface modification (plasma-sprayed hydroxyapatite, sandblasting) or porosity increases surface roughness, allowing for osteoblast attachment.

4. What are the most significant requirements of titanium alloy powder cardiovascular stents?

Ultra-fine powder (nanoscale) and high purity are required for flexibility, fatigue life, and low thrombosis risk.

5. What standards apply to medical-grade titanium alloy powder?

Should be compatible with ASTM F3001 (3D printing) or ISO 5832-3 (surgical implants), with very stringent oxygen/nitrogen impurity and particle size distribution limits.

6. What are the cons of titanium alloy powder implants?

First, Equipment for powder manufacturing and 3D printing is expensive. Otherwise, Heat treatment and surface modification are required for optimal performance.

7. Which is better for medical implants - titanium or zirconium?

Titanium and zirconium each serve different medical needs. Zirconium, specifically zirconia, is mainly chosen for dental crowns and implants because its color resembles natural teeth, and it integrates well with gum tissue. Titanium remains the top choice for load-bearing implants like joint replacements and bone fixation devices due to its exceptional strength and ability to fuse with bone.

Read more: Zirconium Powder vs. Titanium Powder: Comparison of Properties and Applications

8 Can patients with titanium implants safely get CT scans?

Yes. Titanium implants are highly compatible with CT imaging. Unlike stainless steel, which often causes significant image distortions (artifacts), titanium produces minimal interference, allowing for clearer diagnostic results.

9. What types of titanium are used in medical implants?

Ti-6Al-4V, known as Grade 5 titanium, is the most common for orthopedic and dental implants. Commercially pure titanium (CP-Ti) is often selected for less demanding applications where flexibility is beneficial. Ti-6Al-7Nb serves as an alternative for patients who may need vanadium-free options.

[1] Sarraf, M., Rezvani Ghomi, E., Alipour, S. et al. A state-of-the-art review of the fabrication and characteristics of titanium and its alloys for biomedical applications. Bio-des. Manuf. 5, 371–395 (2022). https://doi.org/10.1007/s42242-021-00170-3

[2] Ma, Kai, Zhang, Rui, Sun, Junlong, Liu, Changxia, Oxidation Mechanism of Biomedical Titanium Alloy Surface and Experiment, International Journal of Corrosion, 2020, 1678615, 9 pages, 2020. https://doi.org/10.1155/2020/1678615

United States

.png)