Tungsten and titanium are two critically important metals in industrial applications. While they may appear similar at first glance, they exhibit significant differences in properties and practical uses.

Tungsten (W) is a silver-gray element in Group 6 of the periodic table with an atomic number of 74. It is best defined by having a very high melting point and density. It has the highest melting point (3,422°C) of all the metals, and its density is nearly as high as that of gold. Tungsten is also very hard, only slightly below chromium at room temperature.

Titanium (Ti), a transition element in Group 4 with atomic number 22, has a lower density (4.506 g/cm³) and melting point (1,668°C) than tungsten. It has a silver-gray color, an outstanding strength-to-weight ratio, and excellent corrosion resistance.

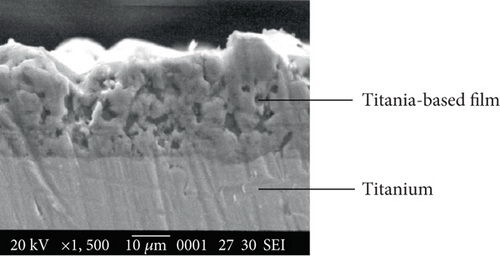

Chemically, tungsten is very stable at room temperature, not corroding by water or air, but is reactive with oxygen at high temperatures to form tungsten trioxide. Titanium forms a dense, self-sealing titanium oxide (TiO₂) layer on the surface of its metal, which makes it have excellent corrosion resistance, even to aqua regia.

|

Property |

Tungsten (W) |

Titanium (Ti) |

|

Atomic Number |

74 |

22 |

|

Density (g/cm³) |

19.25 |

4.506 |

|

Melting Point (°C) |

3,422 |

1,668 |

|

Mohs Hardness |

7.5 |

6 |

|

Crystal Structure |

BCC |

HCP (α-phase) |

|

Electrical Resistivity (nΩ·m) |

52.8 |

420 |

The answer is nuanced, as each has distinct advantages.

Tungsten possesses higher stiffness and deformation resistance due to its compact atomic structure and high atomic bond strength. Its elastic modulus is about 411 GPa, over twice that of steel and close to four times that of titanium. Tungsten possesses outstanding tensile strength to 1,000°C but poor low-temperature or impact brittleness.

Titanium is renowned for its strength-to-weight ratio. Pure titanium possesses a moderate tensile strength (~240 MPa), but alloys like Ti-6Al-4V may possess greater than 1,000 MPa with low weight. Titanium has excellent toughness, fatigue resistance, and biocompatibility, all of which qualify it as the best option for medical implants.

Tungsten possesses higher temperature strength than titanium. Tungsten can maintain structure up to 2,000°C while titanium alloys become excessively soft when the temperature is over 500–600°C. But titanium properties are improved at cryogenic temperatures, whereas tungsten becomes more brittle.

|

Mechanical Property |

Tungsten |

Titanium |

|

Elastic Modulus (GPa) |

411 |

116 |

|

Tensile Strength (MPa) |

Pure: 550–620 |

Pure: 240–370 |

|

Alloys: 1,500+ |

Alloys: 900–1,200 |

|

|

Elongation (%) |

1–3 |

15–25 |

|

Hardness (HV) |

300–700 |

80–200 |

|

Fatigue Limit (MPa) |

Low |

High |

|

Max Service Temp (°C) |

2,000+ |

600 |

Titanium is famous for its resistance to corrosion, particularly under oxidizing conditions and in chloride media. Its naturally healing TiO₂ layer resists seawater, wet chlorine, nitric acid, and even aqua regia.

Tungsten is more complex. Tungsten does not react at room temperature with water, air, or acids (e.g., HCl, H₂SO₄) but oxidizes under oxidizing media (e.g., HNO₃, aqua regia) or upon heating. Alkaline solutions corrode tungsten, too.

Both metals can be made more resistant using alloying.

|

Corrosion Resistance |

Tungsten |

Titanium |

|

Air Oxidation |

>500°C |

Stable to 600°C |

|

Seawater Resistance |

Moderate |

Excellent |

|

HCl Resistance |

Good (room temp) |

Good (dilute) |

|

HNO₃ Resistance |

Poor |

Excellent |

|

NaOH Resistance |

Poor |

Stable (dilute) |

|

Aqua Regia Resistance |

Poor |

Moderate |

Tungsten alloy powders are typically engineered for high density, extreme hardness, or superior high-temperature performance, whereas titanium alloy powders prioritize exceptional strength-to-weight ratios, corrosion resistance, and biocompatibility. With advancements in powder metallurgy and additive manufacturing (3D printing), the application scope for both alloy powders continues to expand significantly.

Tungsten Alloy Powders are used for:

Titanium Alloy Powders dominate in:

They serve the same industries but have distinct purposes.

|

Industry |

Tungsten Powder Uses |

Titanium Powder Uses |

|

Aerospace |

Rocket nozzles, ballast |

Structural parts, engines |

|

Medical |

Radiation shielding |

Implants, prosthetics |

|

Electronics |

Thermal management |

Connectors, casings |

|

Additive Manufacturing |

High-temp tools |

Custom implants, aerospace parts |

1: Which one is more suitable for high heat - titanium or tungsten powder?

Tungsten powder is far more suited for high temperatures. It melts at 3,422°C, while titanium melts at 1,668°C. Tungsten is still strong above 1,000°C.

2: Why is titanium alloy powder employed more than tungsten alloy powder in biomedical uses?

Titanium is nontoxic and safe to be used in the human body. It bonds with bone and will not cause rejection. Tungsten is toxic and too heavy for implants. Tungsten is used by surgeons on radiation shields, though.

3: What is most difficult about 3D printing using these powders?

Tungsten is hard to 3D print using because its melting point is extremely high. This can cause it to crack. Titanium needs careful oxygen control to avoid defects.

4: From a cost perspective, under what circumstances do you apply tungsten alloy powder or titanium alloy powder?

They are both costly. Apply tungsten when you need high heat resistance or hardness. Apply titanium when you require light strength or medical safety applications.

5: Are they recyclable?

Yes, but in varying circumstances. Titanium is readily recyclable in excess of 80% for aerospace. Tungsten is less so, about 30%. Both can be recycled to be used in 3D printing once cleaned.

6: Which has more future uses in powdered form?

They both will have importance. Tungsten expands in energy technology. Titanium expands in aerospace and medical 3D printing. Titanium may expand a bit more.

Stanford Advanced Materials (SAM) provides Titanium Powder and Tungsten Powder of different particle sizes and purity. Feel free to ask us for more details by Get A Quote.

United States

.png)