Tantalum Powder and Titanium Powder are two important metallic powder materials used in industrial applications. Although they share similarities in certain application fields, they exhibit significant differences in performance and specific applications.

Tantalum (Ta) is a rare, gray metal known for its extremely high corrosion resistance and melting point. Tantalum powder is typically produced through arc melting or induction melting methods, followed by further processing via powder metallurgy techniques. The high purity and fine particle size of tantalum powder make it widely used in high-end manufacturing industries.

Titanium (Ti) is a lightweight metal with high strength, excellent specific strength, and good corrosion resistance. Titanium powder is usually prepared through hydrogen reduction, plasma vapor deposition, or mechanical alloying methods and is widely applied in aerospace, medical devices, and additive manufacturing fields.

They have significant differences in many aspects.

1. Density

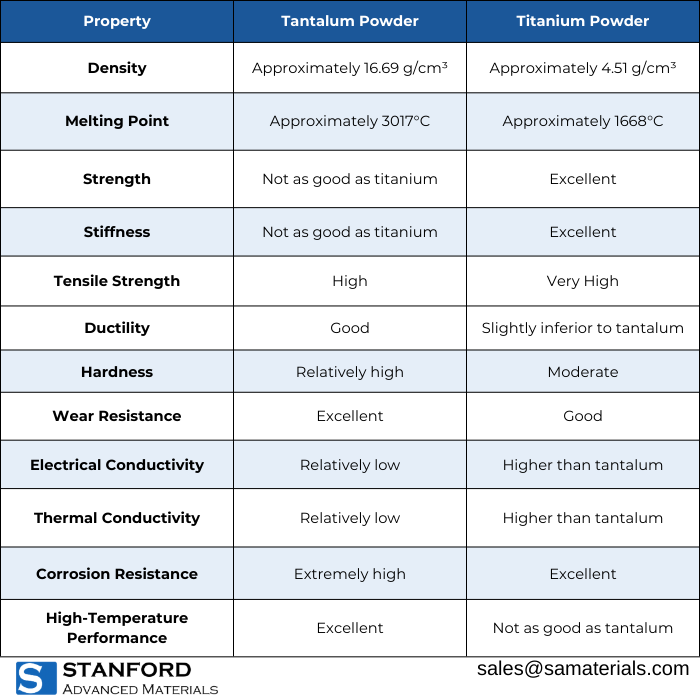

Tantalum has a density of approximately 16.69 g/cm³, making it a high-density metal. This gives tantalum powder an advantage in applications requiring high mass density and weight. In contrast, titanium has a density of about 4.51 g/cm³, significantly lower than tantalum. This makes titanium powder more suitable for applications requiring lightweight materials.

2. Strength and Stiffness:

Titanium is renowned for its high specific strength and excellent stiffness, especially performing well in high-stress environments. Although tantalum's strength and stiffness are inferior to titanium, it possesses high ductility and good tensile strength.

3. Corrosion Resistance:

Tantalum powder exhibits extremely high corrosion resistance, especially in strong acidic environments such as fluoride and sulfuric acid, where it is nearly impervious to attack. Titanium powder also has excellent corrosion resistance but performs slightly less effectively than tantalum in certain strong acidic environments like hydrofluoric acid.

4. Melting Point:

Tantalum powder has an extremely high melting point (approximately 3017°C) and excellent high-temperature strength. Titanium powder has a lower melting point (about 1668°C) and does not perform as well as tantalum at high temperatures, though its heat resistance remains superior among light metals.

5. Hardness and Wear Resistance:

Tantalum powder has higher hardness and superior wear resistance, making it suitable for applications that require durability. Titanium powder has moderate hardness and good wear resistance but is not as wear-resistant as tantalum under extreme conditions.

6. Ductility:

Tantalum powder has good ductility and malleability, making it easy to process into various complex-shaped components. Titanium powder's ductility is slightly inferior to that of tantalum, but its excellent mechanical properties allow it to maintain high strength during processing.

7. Electrical Conductivity and Thermal Conductivity:

Tantalum powder has lower electrical and thermal conductivities, limiting its use in certain electronic and thermal management applications. Titanium powder has higher electrical and thermal conductivities compared to tantalum.

Table 1. Summary of the performance comparison between tantalum and titanium

Both Tantalum Powder and Titanium Powder can be processed through powder metallurgy to produce complex-shaped and high-performance components. However, due to tantalum's high melting point and titanium's reactivity, their specific processing parameters in powder metallurgy differ. In powder metallurgy, tantalum powder requires sintering at high temperatures, usually in an inert gas or vacuum environment to prevent oxidation. Conversely, metallurgical processing of titanium powder necessitates strict control of oxygen content to prevent material brittleness. Sintering is typically performed in a vacuum or inert atmosphere to maintain titanium's high strength and toughness.

Additive manufacturing technologies have opened new horizons for the application of both tantalum and titanium powders, though differences exist between them. The high density and melting point of tantalum powder make the 3D printing process complex, requiring high-energy lasers or electron beams. Additionally, high costs and equipment requirements limit its widespread application. In contrast, titanium powder is widely used in additive manufacturing, especially in aerospace and medical device fields. Due to titanium's lower density and good processing performance, 3D-printed titanium products are more economical and technologically mature.

Tantalum Powder and Titanium Powder share many application fields, but there are specific differences in their applications.

1. Aerospace

Given the high melting point and corrosion-resistant properties of tantalum powder, it is primarily used to manufacture high-temperature components such as rocket engine nozzles and combustion chambers. On the other hand, titanium powder, with its high specific strength and lightweight characteristics, is widely applied in aircraft structural components, engine parts, and turbine blades.

Fig 1. Rocket engine nozzles and engine parts

2. Medical Devices

Both tantalum and titanium possess biocompatibility, making them important materials for medical devices. Tantalum powder is mainly used in artificial joints and dental implants. In contrast, titanium powder is more commonly found in orthopedic implants and prosthetics.

Fig 2. Dental implants and orthopedic implants

3. Electronics and Electrical

In the electronics industry, tantalum powder is primarily used to manufacture tantalum capacitors, which are essential key components in modern electronic devices. Conversely, titanium powder has relatively fewer applications in the electronics industry, mainly being used in certain specific electronic components and cooling devices.

Fig 3. tantalum capacitors

4. Tools and Molds

Tantalum powder is mainly used to manufacture high-wear-resistant tools and molds, especially excelling in high-temperature and corrosive environments. Meanwhile, titanium powder is used to create various high-strength and lightweight tools and molds, particularly suitable for applications requiring complex shapes and high performance.

With the continuous enhancement of performance requirements in high-tech industries, the demand for tantalum powder in electronics, aerospace, and medical devices will continue to grow. To reduce costs and improve supply chain sustainability, the development of tantalum recycling technologies and research into alternative materials will become important future directions.

The rapid development of additive manufacturing technology has opened up more application prospects for titanium powder, especially in personalized medicine and complex structural manufacturing. In the future, with the optimization of production processes and further cost reductions, the application range of titanium powder will expand further. Additionally, the development of titanium alloys and the exploration of new materials will promote the continued growth of the titanium powder market.

Choosing between Tantalum Powder and Titanium Powder depends on the specific application requirements and performance needs. For applications requiring high density, exceptional corrosion resistance, and high-temperature stability, Tantalum Powder is the preferred material. Conversely, for applications that prioritize lightweight, high strength, and economic feasibility, Titanium Powder is more suitable.

Stanford Advanced Materials (SAM) provides Titanium Powder and Tantalum Powder of different particle sizes and purity. Feel free to ask us for more details by Get A Quote.

United States

.png)