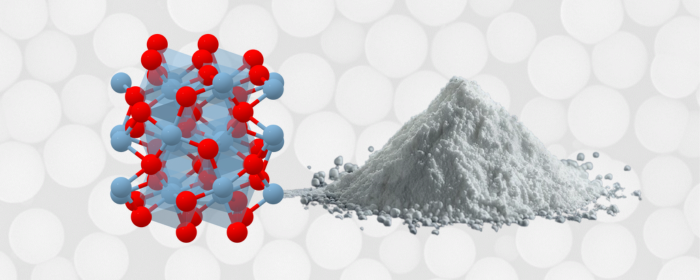

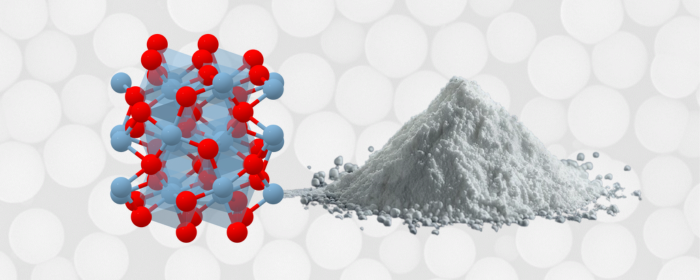

Metal powders are some of the most critical raw materials involved in additive manufacturing and 3D printing. Flowability, morphology, and purity of the powder dictate the 3D printing process. These properties not only depend on the preparation process but are also dictated by the storage management of the metal powders once produced.

Behind any standardized requirement lies the lessons learned from past experiences. The metal powder quality directly contributes to mechanical properties, dimensional tolerances, and surface finish of printed components. Improper storage can lead to the following issues:

Therefore, scientific and rational storage procedures not only prolong the service life of powders but also ensure safety and stability of the printing process.

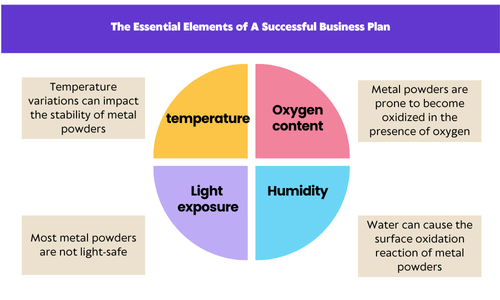

The first one is the environmental humidity. Water can cause the surface oxidation reaction of metal powders, especially reactive metals like aluminum and titanium. This not only alters the powder's chemical composition but also easily causes clumping.

Metal powders typically have a larger specific surface area, which leads to greater reactivity. Metal powders are prone to become oxidized in the presence of oxygen. It is seen in experiments that at standard atmospheric conditions (21% O₂), the surface oxide layer of aluminum powder with nano-size may be developed 5–8 nm thick in 24 hours.

Temperature variations can impact the stability of metal powders. Too high temperatures promote oxidation, and too low temperatures can lead to condensation, both of which degrade powder quality.

Most metal powders are not light-safe since ultraviolet (UV) light rays can catalyze the oxidation of certain metal powders. For example, UV ray exposure catalyzes cuprous oxide (Cu₂O) to become copper oxide (CuO) in copper powder, changing the color of the powder from red to black but significantly increasing oxygen levels.

In summary, humidity, oxygen content, temperature, and light exposure can all induce changes in metal powders.

Storage of metal powder needs to comply with stringent environmental control and packing requirements. To begin with, the storage containers have to be constructed from 304 or 316L stainless steel. Moreover, A double-layer sealing structure is coupled with fluororubber O-rings for a hermeticity standard with a leakage rate of ≤1×10⁻⁶ mbar·L/s.

Generally, powders of particle size >53μm are fillable in air. However, powders of particle size <53μm should be filled in an inert gas environment. Even if the particle size of reactive metal powders is >53μm, they need high-purity inert gas sealage. Argon or nitrogen, etc., should be inert gases with a purity of ≥99.999%.

Moreover, ambient temperature and humidity need to be strictly controlled. There should be a constant temperature in the storage area, preferably between (20±2)°C, and fluctuation not more than ±0.5°C per hour. Relative humidity should be controlled below 15%RH. Humidity should be further reduced to below 5%RH for nano-sized metal powders.

Powders must be stored in a clean, dry, and well-ventilated warehouse and must not be stored near acids, alkalis, corrosive substances, explosive/flammable substances, or reactive materials. Different categories of powders must have a minimum of 1.5 meters safety distance between them, but extremely reactive chemicals must have a distance of not less than 3 meters.

Certain metal powders exhibit varying degrees of sensitivity to the aforementioned factors and may require more stringent storage conditions.

Titanium alloy powders, such as Ti-6Al-4V, demand particular attention to oxygen control. The oxygen concentration in the storage environment must not exceed 10ppm. It is advisable to use specialized containers that undergo vacuum degassing before being filled with high-purity argon. Nitrogen should be avoided as a protective gas to prevent nitridation, which could compromise material properties.

Aluminum alloy powders, like AlSi10Mg, are highly sensitive to humidity. In addition to standard humidity control measures, oxygen indicators and humidity indicator cards should be placed inside containers to monitor environmental conditions in real time. The storage area must be equipped with a comprehensive electrostatic protection system, including anti-static flooring and ionizing fans, to maintain electrostatic potential within safe limits.

Stainless steel powders, such as 316L, exhibit relatively good chemical stability but still require protection against chloride-induced corrosion. The storage area should be isolated from chlorine-containing environments, and VCI (vapor corrosion inhibitor) anti-rust tablets can be placed inside containers for added protection. For batches intended for long-term storage, oxygen content and flowability tests should be conducted every three months.

Nickel-based superalloy powders, including Inconel 718, require special attention to temperature stability. In addition to maintaining a constant temperature environment, frequent temperature fluctuations should be avoided to prevent powder aging. These materials are best stored in smaller, pre-portioned quantities, with immediate resealing after each use to minimize exposure to external environmental factors.

* The metal 3D printing powders mentioned above are all available from Stanford Advanced Materials (SAM), which implements strict storage and transportation conditions.

Metal powder storage management is a critical aspect of additive manufacturing that cannot be overlooked. Proper storage methods not only extend powder lifespan and reduce production costs but also ensure print quality and operational safety. Companies should establish tailored storage protocols based on the characteristics of different metal powders, combined with regular inspections, to guarantee the stability and reliability of the 3D printing process.

1. What are the most widely used metal powders in 3D printing?

Stainless steel, titanium alloys, aluminum alloys, nickel-based superalloys, and tool steels are some of the most widely used metal powders. These are widely utilized in aerospace, medical, and automotive industries due to their extremely good mechanical properties and resistance to corrosion.

2. Are metal powders vacuum-packed?

For powders of fine particle size (<53μm) or highly reactive metal powders, like titanium and aluminum, vacuum or inert gas sealing is mandatory. General metal powders can use moisture-proof sealed containers for short-duration storage, but long-duration storage is still required with inert protection.

3. What are the problems with inadequate storage?

Humidity leads to oxidation and agglomeration, oxygen exposure decreases sintering performance, static generation can initiate dust explosions, and temperature variation speeds up material aging. All of these have a direct influence on print quality and production safety.

4. How to guarantee safe storage of metal powders?

Main measures are keeping constant temperature (20±2°C) and humidity (<15%), double-sealed stainless steel containers, anti-static provisions (e.g., ionizers), insulation from corrosive materials, and frequent monitoring of powder condition.

5. Why are powders that are very reactive shielded by an inert gas?

Argon/nitrogen environments exclude oxygen and moisture, avoiding oxidation of very reactive metals like titanium and aluminum. This maintains powder flowability and chemical stability, which is critical to upholding the mechanical properties and surface finish of printed parts.