Magnetic materials are broadly classified into permanent magnets and soft magnets. Permanent magnets, also known as hard magnets, retain their magnetism for long periods and have high coercivity, making them resistant to demagnetization. In contrast, soft magnetic materials have low coercivity and high magnetic permeability, which allows them to be easily magnetized and demagnetized. These materials are crucial for magnetic guidance and the conversion and transmission of electromagnetic energy, widely used in power conversion devices in the electronic and electrical industries.

Soft magnetic materials can be categorized into three main types: metallic soft magnets, ferrite soft magnets, and amorphous and nanocrystalline soft magnets.

Iron Powder Cores: Made from pure iron powder with surface insulation, mixed with organic binders. Used in energy storage inductors, dimming reactors, EMI noise filters, and DC output/input filters.

Carbonyl Iron Powder Cores: Composed of ultra-fine pure iron powder, ideal for high-frequency applications such as high-frequency switching circuit output chokes and resonant inductors.

Iron-Silicon-Aluminum Powder Cores: An alloy powder of Fe, Si, and Al, used in PFC inductors, pulse transformers, and energy storage inductors.

Iron-Silicon Powder Cores: Made from an alloy powder of Fe and Si, suitable for high current reactors and power inductors in renewable energy sectors like solar and wind energy.

High Flux Powder Cores: Offer the highest magnetic flux density, excellent DC bias characteristics, and low losses. Ideal for high power and high DC bias applications.

Iron-Nickel-Molybdenum Powder Cores: Made from an alloy of Fe, Ni, and Mo, known for high permeability, high resistivity, low hysteresis, and low eddy current losses. Used in transformers, high Q filters, and PFC inductors.

Iron Powder Cores

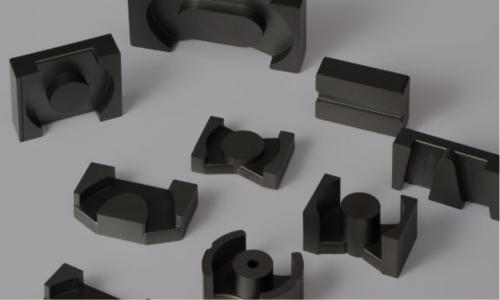

Ferrite soft magnetic materials are composed of iron oxides and other metal oxides, offering high permeability, low losses, and resistance to corrosion and high temperatures. They are cost-effective and suitable for large-scale production, commonly used in inductors, transformers, filters, and magnetic recording devices.

Manganese-Zinc Ferrite (MnZnFe₂O₄): Used for applications requiring high permeability and high magnetic induction.

Nickel-Zinc Ferrite (NiZnFe₂O₄): Suitable for high-frequency applications due to its high resistivity and low eddy current losses.

Ferrite soft magnetic materials

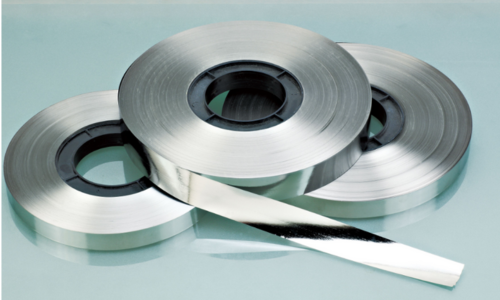

These materials combine high saturation magnetic induction, high permeability, low losses, and excellent temperature stability. They are seen as green energy-saving materials of the 21st century, widely used in information communication and power electronics, promoting the miniaturization and energy efficiency of electronic products.

Amorphous Alloys: Also known as "liquid metal" or "metallic glass," these include elements like iron, silicon, and boron. They are characterized by low coercivity, high permeability, high resistivity, and resistance to high-temperature corrosion.

Nanocrystalline Materials: Primarily iron-based alloys, formed by rapid cooling of an amorphous alloy followed by controlled annealing to create a structure with nanoscale crystallites. They offer superior performance in terms of high saturation flux density, high permeability, and high Curie temperature, making them suitable for inductors, transformers, sensors, and other components.

Amorphous Alloy Strip

Stanford Advanced Materials (SAM) is at the forefront of developing alloy powders, providing high-performance metallic soft magnetic powders and nanocrystalline powders. For more information or specific applications about these soft magnetic powders, please feel free to contact and view our home page.

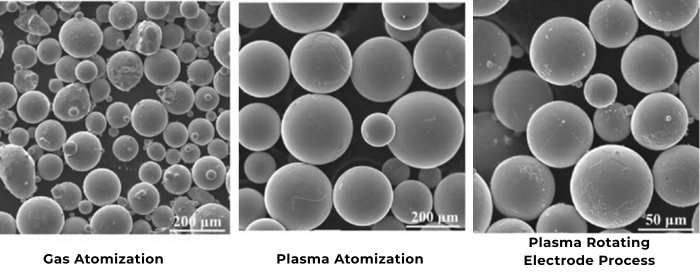

The powder metallurgy of soft magnetic alloy powders is complex, involving powder preparation, insulation coating, pressing, and heat treatment. Among them, the powder preparation is the primary process, and the mainstream processes can be divided into three types: gas atomization, water atomization, and crushing.

The method of powder preparation uses high-pressure nitrogen to break and cool molten steel into powder. The sphericity of aerosolized powder is relatively better, so that the surface of the insulating layer in the subsequent pressing process is more complete and the pressing density is higher. As a result, it has the characteristics of high resistivity and excellent DC bias. Therefore, the powder produced by the gas atomization method has the best overall performance, but the process itself is also more difficult.

The principle of this process is to use water as a medium to cool high-temperature liquid alloy. Since water can be recycled, the cost is reduced. However, the disadvantage is that water will decompose oxygen molecules, which will oxidize the metal surface and increase the stone powder content, making it unusable for high-frequency components. In addition, in terms of magnetic loss, water atomization is also different from gas atomization. Therefore, compared with gas atomization, the water atomization method is cheaper and easier to prepare powder, but the quality of the powder produced is lower.

The steps of the crushing method are to first lift the grinding body in the cylinder to a certain height and give it potential energy and projectile kinetic energy. Then, the grinding body with a certain initial speed falls along a parabolic trajectory, impacting and grinding the material fed from the feed end of the mill over and over again, so that the material between the grinding media is impacted and crushed, thereby obtaining magnetic powder. Overall, the powder produced by this method has average performance but high-cost performance.

Soft magnetic materials are widely used in modern industry and technology, usually as important materials for transformers, inductors, communication equipment, and induction cookers. In addition, with the development of technology and the rise of emerging industries, this material has broad application needs in renewable energy, new energy vehicles, and 5G communications industries.

Power Electronics: Transformers and inductors use soft magnetic materials to improve magnetic flux density and reduce energy losses.

Consumer Electronics: Used in power management modules of phones and computers to reduce EMI and improve efficiency, and in wireless chargers to enhance energy transmission efficiency.

Automotive Industry: Electric motors and generators in electric vehicles, as well as various magnetic sensors, benefit from soft magnetic materials.

Communication Devices: Filters and chokes in communication equipment use these materials to reduce EMI and maintain signal quality.

Medical Equipment: Magnetic resonance imaging (MRI) devices and inductive medical sensors utilize soft magnetic materials for their magnetic properties.

Household Appliances: Soft magnetic materials are used in efficient induction heating systems of electromagnetic cookers and electric motors in various appliances.

Renewable Energy: Wind turbines and solar inverters benefit from high-performance soft magnetic materials to enhance efficiency and reliability.

Electric Vehicles (EVs): High-efficiency, lightweight soft magnetic materials improve the performance and range of electric vehicles.

5G Communication: High-frequency filters and miniaturized antennas in 5G devices require advanced soft magnetic materials to enhance performance.

Smart Grids: Soft magnetic materials improve the efficiency and reliability of transformers and other power electronics in smart grids.

Medical Technology: High-frequency medical devices and biosensors benefit from soft magnetic materials for their stability and precision.

Internet of Things (IoT): Low-power, high-efficiency sensors and wireless energy transfer systems in IoT devices rely on advanced soft magnetic materials to improve performance and efficiency.

Soft magnetic materials play an indispensable role in modern industry and technology. Whether it is traditional power electronics, consumer electronics, automobile industry, or emerging renewable energy, 5G communications, smart grid and other fields, soft magnetic materials have shown great application potential. With the continuous advancement of technology, soft magnetic materials will continue to promote the development of all walks of life and bring more possibilities to our future.

Related articles:

The Role of Soft Magnetic Powder in Technology: Identification and Applications