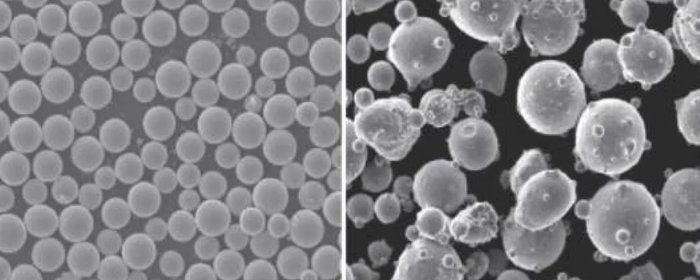

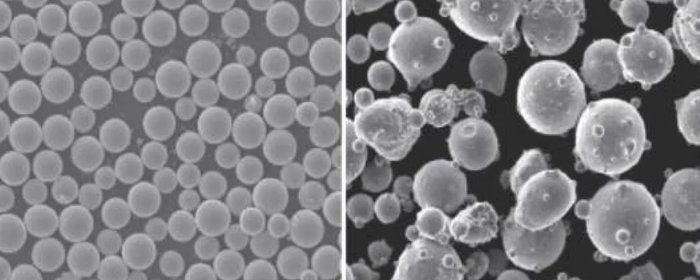

C103 spherical powder is a high-temperature alloy based on niobium (Nb). It is renowned for its excellent high-temperature performance and corrosion resistance, making it widely used in aerospace, energy, chemical industries, and other fields. With the growing demand for high-temperature materials and the development of additive manufacturing technologies, the application market and scope for C103 are expanding.

C103 is a specific type of niobium-based alloy primarily consisting of niobium (Nb) with additions of other elements such as titanium (Ti), zirconium (Zr), hafnium (Hf), and molybdenum (Mo). It is not a family of alloys but rather a distinct alloy with a well-defined composition. However, niobium-based alloys can vary slightly in composition to tailor them for specific applications. The typical composition ratios are:

Table 1. C103 Spherical Powder Specifications

.png)

C103 spherical powder is a high-temperature niobium-based alloy characterized by its excellent high-temperature performance, including a high melting point of 2468°C, outstanding creep resistance, and thermal stability. It also offers superior mechanical properties at elevated temperatures, good ductility, exceptional corrosion resistance in various chemical environments, high thermal conductivity, and relatively low density.

1. Excellent High-Temperature Performance

C103 Spherical Powder is renowned for its outstanding high-temperature performance. Its melting point reaches up to 2468°C, and it maintains good creep resistance and mechanical strength at high temperatures.

Creep Resistance: The material can maintain its shape and size for a long time under high-temperature conditions without significant plastic deformation.

Thermal Stability: It does not easily undergo phase changes or performance degradation in high-temperature environments.

Fig 1. Comparison of plastic region of engineering stress-strain plots at various temperatures[1]

2. Superior Mechanical Properties

C103 spherical powder exhibits excellent mechanical properties, especially at high temperatures. Its tensile strength and ductility remain high under high-temperature conditions.

Fig 2. Tensile properties of Nb based C 103 alloy at various temperatures[2]

3. High Ductility

The Ni-Hf alloy retains good ductility at high temperatures, allowing it to withstand deformation without breaking.

4. Corrosion Resistance

C103 spherical powder has excellent corrosion resistance in various chemical environments, particularly in high-temperature oxidation and sulfidation conditions. This makes it suitable for harsh chemical and aerospace environments.

5. High Thermal Conductivity and Low Electrical Conductivity

C103 has low electrical conductivity. However, it has high thermal conductivity, around 54 W/m·K. This makes it better than other high-temperature alloys in heat transfer.

6. Low Density

The density of C103 is 8.6 g/cm³, which is relatively low compared to many high-temperature alloys, making it advantageous for applications where weight reduction is critical.

The physical properties of C103 niobium-hafnium alloy make it an ideal material in many industries. In fact, it widely used in aerospace, additive manufacturing, energy and chemical industries.

The aerospace industry extensively uses C103 spherical powder, particularly for manufacturing rocket engine components, nozzles, combustion chambers, and heat shields.

Rocket Engine Nozzles: Nozzles must withstand extremely high temperatures and pressures, making the high-temperature performance and corrosion resistance of C103 alloy ideal.

Combustion Chambers: The temperatures inside combustion chambers are extremely high, and the creep resistance and thermal stability of C103 spherical powder ensure long-term use under harsh conditions.

The energy industry uses C103 spherical powder as structural material and corrosion-resistant coatings. Many parts need to operate long-term in high-temperature and corrosive environments, making C103 alloy an ideal choice due to its high-temperature and corrosion resistance.

Heat Exchangers: Heat exchangers operating under high-temperature conditions require high thermal conductivity and corrosion resistance, which C103 spherical powder can provide.

The chemical industry uses C103 spherical powder to manufacture high-temperature corrosion-resistant equipment and components.

Chemical Reactor Linings: Chemical reactors operate under high temperature and pressure, and C103 alloy can effectively prevent corrosion and mechanical damage.

High-Temperature Furnace Tubes: Furnace tubes operating under high-temperature conditions require materials with good creep resistance and corrosion resistance, such as C103 alloy.

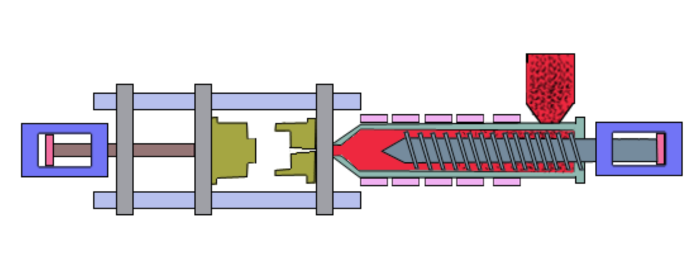

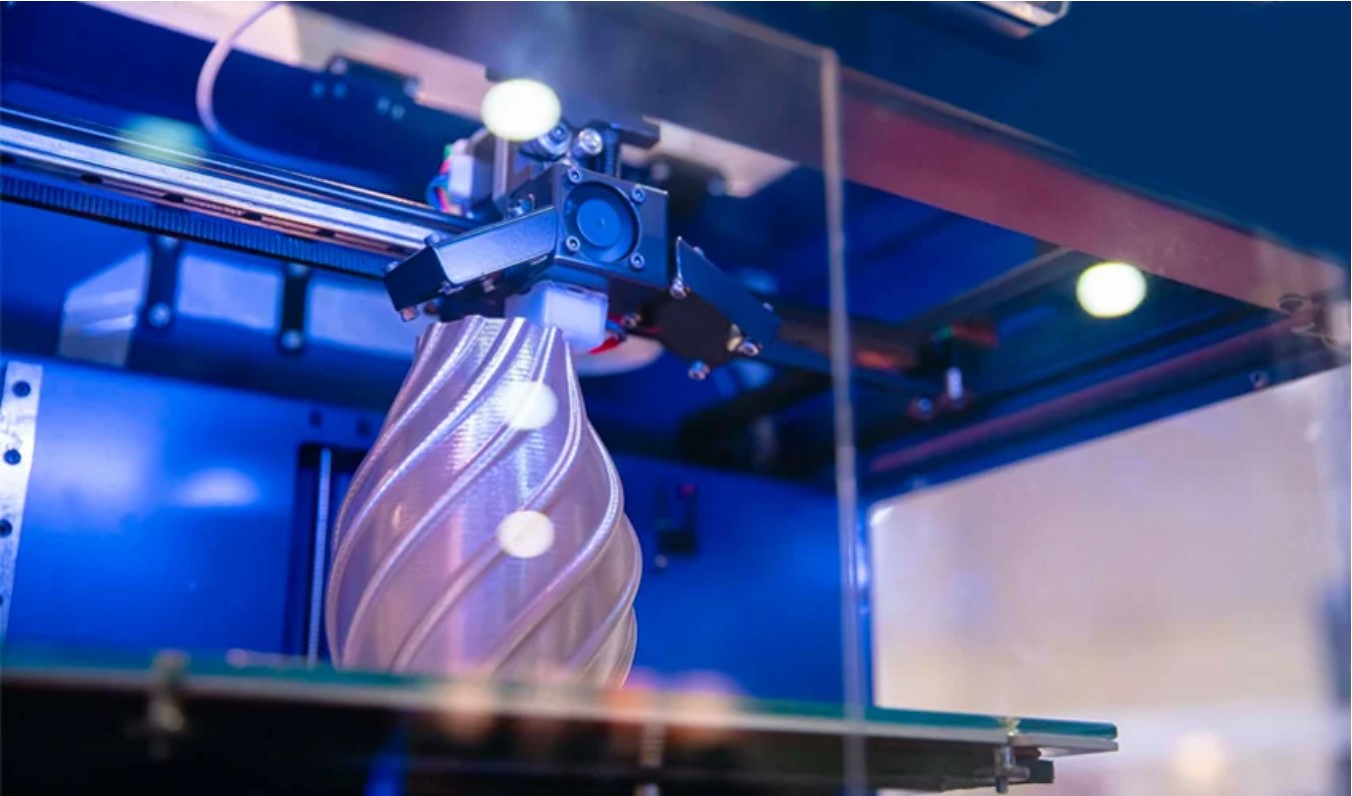

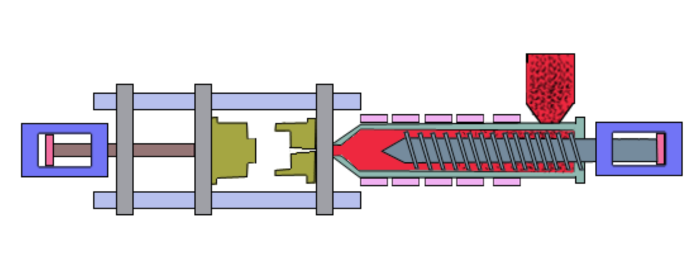

C103 spherical powder is particularly suitable for 3D printing technology, used to produce complex-shaped high-performance components.

Aerospace Engine Blades: C103 alloy blades manufactured using 3D printing technology can reduce material waste and improve component performance.

Medical Devices: In the production of complex medical device components that need to withstand high-temperature sterilization, C103 spherical powder enables precision manufacturing through additive manufacturing technology.

With the advancement of technology, the demand for C103 spherical powder is also growing. Therefore, this spherical powder has broad development prospects in the future.

The aerospace, energy, and chemical industries have growing demand for high-temperature materials. As space technology advances, the demand for high-performance nozzles and combustion chamber materials will also rise.

Advances in 3D printing technology are making the application of C103 spherical alloy powder in manufacturing complex components increasingly widespread and important. Additive manufacturing technology can significantly reduce production time and costs while improving material utilization.

Based on the excellent performance of C103 alloy, research institutions and companies are likely to continue developing new niobium-based alloys to meet higher performance requirements. For example, improving alloy composition to further enhance high-temperature performance and corrosion resistance.

Due to its corrosion resistance and high thermal efficiency, C103 spherical powder has broad prospects in environmentally friendly materials. It helps reduce material waste and environmental pollution. Using C103 alloy in high-temperature operating equipment can significantly extend equipment lifespan and reduce waste generation.

Stanford Advanced Materials (SAM) is at the forefront of alloy powder development, providing high-performance C103 Spherical Powder. (Table 1. shows the proportions of various components such as hafnium, titanium, niobium, zirconium, and molybdenum in C103 spherical powder.) For more information about C103 powder, please feel free to contact and check out our homepage.

C103 spherical powder, with its superior properties, has wide applications and development potential in multiple high-tech fields. As related technologies advance, its application scope and market prospects will broaden even further.

[1] Panwar, Shivpal & Prasad, Kartik & Patro, T & Balasubramanian, Krishnamoorthi & Venkataraman, T. (2014). On the occurrence of dynamic strain aging in C-103 Nb based alloy. Materials Science and Engineering A. 620. 286-292. 10.1016/j.msea.2014.10.016.

[2] Panwar, Shivpal & Prasad, Kartik & Patro, T & Balasubramanian, Krishnamoorthi & Venkataraman, T. (2014). On the occurrence of dynamic strain aging in C-103 Nb based alloy. Materials Science and Engineering A. 620. 286-292. 10.1016/j.msea.2014.10.016.