Molybdenum-rhenium (Mo-Re) alloy powder is a powder product consisting of two refractory metal constituents: molybdenum (Mo) and rhenium (Re). It is an alloy product on the basis of molybdenum with the addition of rhenium. This alloy powder combines the high melting point and strength of molybdenum with the excellent ductility and resistance against corrosion of rhenium. The rhenium content is typically in the range of 11% to 50%. In addition to Mo and Re, the powder may be accompanied by trace amounts of O, Fe, Ni, Cr, Cu, and Si.

The refractory molybdenum possesses good thermal and electrical conductivity, corrosion resistance, a low thermal expansion coefficient, high hardness, and high-temperature strength. Pure molybdenum, however, possesses poor room-temperature ductility, machinability, and weldability and has drawbacks such as susceptibility to oxidation and recrystallization embrittlement, limiting its usage in industry. Various methods have been investigated by scientists to improve pure molybdenum's low-temperature brittleness, e.g., regulation of impurity elements, change in annealing process parameters, or addition of transition alloying elements. Of these, rhenium (Re) introduction is generally regarded as one of the most efficient means to improve the low-temperature toughness of molybdenum.

Being a high-temperature material fabricated from refractory molybdenum and rhenium, Mo-Re alloy powder has imperative applications across different industries.

1. Aerospace Industry

Due to its high-temperature superior strength and corrosion resistance, Mo-Re alloy powder is extensively utilized in aerospace applications such as jet engine components, combustion chambers, nozzles, and turbine blades. These components ensure enhanced engine performance and longevity.

2. Electronics Industry

Mo-Re alloy powder has widespread uses in electronic tubes, special lamp components, electron probes, and sputtering targets due to its high thermal stability and electrical conductivity. The alloy's high electron emissivity and resistance render the alloy highly suitable to various gas atmospheres.

3. Semiconductor Industry

The alloy is used in high-temperature components and thermocouple wires for semiconductor manufacturing, where its superior thermal and mechanical characteristics are highly desirable.

4. Chemical Industry

While not a large application, the corrosion resistance and strength of Mo-Re alloy at elevated temperatures make it attractive for utilization in chemical equipment, i.e., reactors, heat exchangers, and valves. It is also used in industrial heating elements for high-temperature furnaces.

5. Medical Field

Less widespread than bulk Mo-Re alloys, the biocompatibility and wear resistance of the powder open up opportunities for medical implants, i.e., bone prostheses and artificial joints.

The rhenium content significantly influences the properties of Mo-Re alloy powder in multiple aspects.

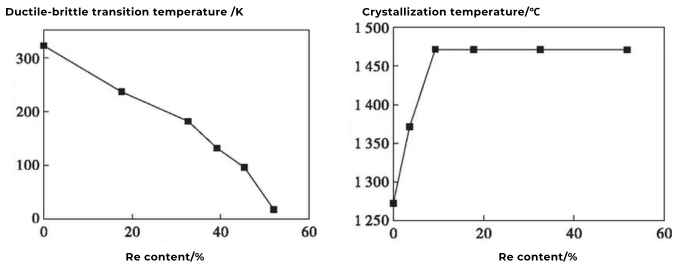

As shown in Fig. 1, the rhenium content has effects on the ductile-brittle transition temperature (DBTT) and recrystallization temperature of Mo-Re alloys. The incorporation of increasing levels of rhenium substantially lowers the DBTT. Pure molybdenum has a DBTT approaching room temperature but with a reduction upon the decrease in rhenium content to the lowest value -254°C when Re content is 51%. In addition, the recrystallization temperature of Mo-Re alloys increases with rhenium content. For Re contents over 10%, the recrystallization temperature can be up to 1,500°C—some 250°C higher than pure molybdenum (1,250°C).

Fig. 1. Effect of Rhenium Content on Ductile-Brittle Transition Temperature and Recrystallization Temperature

As far as mechanical properties are concerned, increased rhenium content enhances both the yield strength and tensile strength of Mo-Re alloys and enhances ductility too. Rhenium addition also enhances machinability, particularly with Re contents over 25%, with much-enhanced weldability.

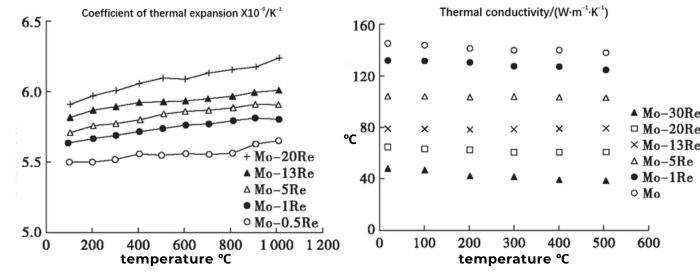

Thermophysically, thermal conductivity decreases with increasing rhenium content at the same temperature because pure rhenium is less thermally conductive than pure molybdenum. The coefficient of thermal expansion (CTE) increases with rhenium content because Re has a higher CTE than Mo.

Fig. 2. Effect of Rhenium Content on Thermal Expansion Coefficient and Thermal Conductivity of Molybdenum-Rhenium Alloy

Moreover, the recrystallization temperature of Mo-Re alloys rises with a high content of rhenium. Above 10% Re, the recrystallization temperature is above 1,200°C. Moreover, rhenium content reduces the anisotropy of the alloy. For 50% Re content, the alloy is isotropic.

Summary:

An optimum content of rhenium can significantly improve the high-temperature characteristics, mechanical properties, and machinability of the alloy powder. Too much Re, however, may result in the development of brittle phases, which have a deleterious effect on overall performance. Thus, it is necessary to optimize the content of rhenium for optimum Mo-Re alloy characteristics.

Stanford Advanced Materials (SAM) offers molybdenum-rhenium (Mo-Re) alloy powders with rhenium content ranging from 10.00% to 55.50%, such as Mo52.5Re47.5. For inquiries, please contact our professional sales team for pricing information: Get A Quote.

United States

.png)