At present, metal nanopowders have broad application prospects in many fields such as electronics, medical care, energy, and automobiles. With the advancement of technology and the continuous expansion of the market, the application fields of metal nanopowders will be further expanded.

Metal nanopowders are tiny particles of metals that have at least one dimension less than 100 nanometers. To put this into perspective, a nanometer is one-billionth of a meter, making these particles extraordinarily small. Because of their minuscule size, metal nanoparticles exhibit unique properties that are not observed in their bulk counterparts. These enhanced properties make these nanoparticles valuable across various industries, from electronics to healthcare.

Metal nanopowders possess several advantages over traditional metal powders, making them highly sought after in advanced technological applications:

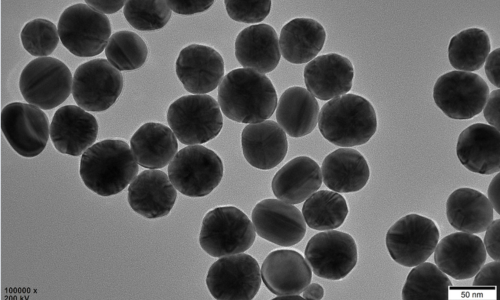

Fig 1. Metal nanoparticles

There are several methods to produce metal nanopowders, each with its own advantages and challenges. Some of the common methods include:

This method involves the mechanical grinding of bulk metals into fine powders. High-energy ball mills are often used to achieve the desired particle size. While effective, this method can sometimes introduce impurities and require extensive time and energy.

In this process, metal salts are reduced using chemical agents to produce metal nanopowders. This method offers good control over particle size and purity but may involve complex chemical handling and waste disposal.

This technique involves the electrochemical deposition of metals onto a substrate, followed by the removal of the substrate to obtain metal nanopowders. It provides high purity and control over particle size but can be limited to specific metals.

This method includes techniques like chemical vapor deposition (CVD) and physical vapor deposition (PVD), where metal vapors condense onto a substrate to form metal nanopowders. These techniques offer precise control over particle size and composition but can be expensive and require specialized equipment.

This technique involves the transition of a solution into a gel and subsequently into a powder. It offers excellent control over the chemical composition and size of the particles, making it suitable for producing high-purity metal nanopowders.

Metal nanopowders find applications in various fields due to their unique properties.

Metal nanopowders are essential in the electronics industry for the development of high-performance electronic components. Their superior electrical conductivity and magnetic properties make them ideal for use in sensors, conductive inks, and electromagnetic interference (EMI) shielding materials. For instance, silver nanoparticles are widely used in printed electronics for creating highly conductive circuits in flexible and wearable devices.

In the energy sector, metal nanopowders play a crucial role in enhancing the efficiency and performance of energy storage and conversion devices. They are used in the development of advanced batteries, fuel cells, and supercapacitors. For example, nickel and cobalt nanopowders are utilized in lithium-ion batteries to improve their energy density, charge-discharge rates, and overall lifespan.

Metal nanopowders have significant applications in the medical field, particularly in drug delivery, imaging, and diagnostics. Their small size allows them to interact with biological systems at the cellular level, providing targeted drug delivery and enhanced imaging contrast. Gold and silver nanopowders are often used in medical imaging and as carriers for anticancer drugs, improving treatment efficacy and reducing side effects.

In the automotive industry, metal nanopowders are used to develop lightweight and high-strength materials, improving fuel efficiency and reducing emissions. They are also employed in catalytic converters to enhance the efficiency of exhaust gas treatment. Aluminum and titanium metal nanopowders are commonly used to produce strong, lightweight components for automotive applications.

.png)

Fig 2. Titanium nanoparticles

Stanford Advanced Materials (SAM) was founded in 1994 to provide customers with first-class metal powders and alloy powders. We have selected a wide range of manufacturers to provide you with high-quality nano-metal powders:

Metal nanopowders represent a groundbreaking advancement in materials science, offering unique properties and significant advantages over traditional metal powders. Their production methods, applications, and future development trends highlight their potential to revolutionize various industries, from electronics and energy to healthcare and automotive.

United States

.png)