Zirconium is known for its remarkable corrosion resistance, extremely high melting point, ultra-high hardness, and strength. Zirconium-based powders are materials composed mainly of zirconium, processed into micron or nanometer-sized particles. These powders typically include pure zirconium powder, zirconium oxide powder, and various zirconium alloy powders. Zirconium-based powders are widely used in industries such as electronics, ceramics, glass, petrochemicals, construction, pharmaceuticals, textiles, and consumer goods.

Metallic zirconium powder is a fine powder made from high-purity zirconium metal. It plays a critical role in nuclear and high-temperature material fields.

A standout feature of metallic zirconium is its extremely low neutron absorption cross-section (approximately 0.18 barn), making it an ideal structural material for nuclear reactors. Additionally, metallic zirconium powder demonstrates exceptional corrosion resistance in high-temperature and corrosive environments, resisting acids, alkalis, and salts (it is soluble in hydrofluoric acid and aqua regia).

With a melting point of 1855°C and excellent thermal stability, it is well-suited for structural materials in high-temperature settings. Furthermore, metallic zirconium powder offers high strength and good ductility, making it easy to fabricate into complex components.

Key Applications of Metallic Zirconium Powder:

Fig 1. Zirconium Powder

Zirconium oxide powder (ZrO₂) is a critical functional ceramic material with exceptional mechanical, thermal, and electrical properties.

Zirconium oxide is among the strongest ceramic materials mechanically. Its unique phase transformation toughening effect enables outstanding fracture resistance. With a melting point of 2700°C, zirconium oxide powder offers excellent thermal stability, surpassing metallic zirconium powder. Additionally, it retains the corrosion resistance of metallic zirconium powder.

Unlike metallic zirconium, zirconium oxide powder has a high dielectric constant. It functions as an excellent electrical insulator at room temperature and maintains its insulation properties in high-temperature environments. Stabilized zirconium oxide (e.g., doped with yttrium or calcium) exhibits exceptional ionic conductivity at high temperatures. Moreover, zirconium oxide powder is non-toxic, harmless, and biocompatible to human tissues.

Key Applications of Zirconium Oxide Powder:

Fig 2. Zirconia Ceramics

Zirconium alloy powders consist of zirconium combined with other metallic elements such as titanium, tungsten, and copper. The properties and applications vary depending on the added elements.

Titanium-zirconium powder is a high-performance alloy combining the unique advantages of titanium (Ti) and zirconium (Zr). With a relatively low density of about 4.5 g/cm³, it offers an exceptionally high strength-to-weight ratio. Both titanium and zirconium possess excellent chemical corrosion resistance, a characteristic shared by titanium-zirconium powder. Additionally, this alloy powder is non-toxic, harmless, and biocompatible with human tissues.

Overall, titanium-zirconium powder, known for its lightweight, high strength, and biocompatibility, is used in aerospace and medical fields.

The zirconium-tungsten powder is an alloy made from zirconium (Zr) and tungsten (W). Both elements have extremely high melting points, and the resulting alloy powder boasts an ultra-high melting point of 2800°C. Combining tungsten’s excellent electrical conductivity with zirconium’s stability, zirconium-tungsten powder is an efficient electrode material. Moreover, it exhibits superior thermionic emission properties.

With its outstanding high-temperature resistance, conductivity, and optoelectronic performance, zirconium-tungsten powder is widely applied in welding, electric light source manufacturing, and aerospace industries.

Copper-zirconium powder is a high-performance alloy made from copper (Cu) and zirconium (Zr).

This alloy retains copper’s high electrical conductivity, with electrical conductivity close to pure copper (about 80-90% IACS). Meanwhile, the addition of zirconium enhances copper’s hardness and wear resistance, making it suitable for high-frequency, high-intensity electrical discharge machining (EDM) and resistance welding. Under high-temperature conditions, the copper-zirconium alloy offers much better thermal fatigue resistance than pure copper, making it ideal for applications requiring extreme temperature changes.

With excellent conductivity, wear resistance, and thermal fatigue resistance, copper-zirconium powder is an essential material in electrical engineering and machining.

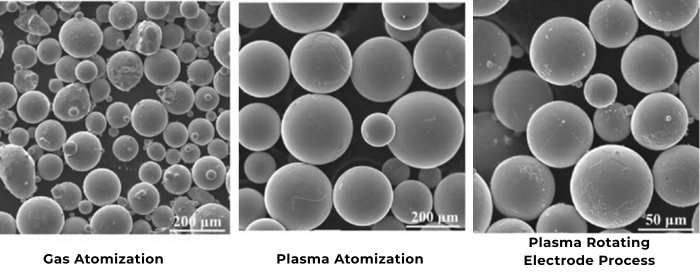

Stanford Advanced Materials (SAM), established in 1994, is dedicated to providing customers with top-quality metal and alloy powders. Our wide range of spherical metal powders includes zirconium-based, nickel-based, titanium-based, stainless steel, and high-entropy alloy powders, catering to diverse manufacturing needs. If you have relevant requirements, feel free to request a quote.

Reference:

Overview of Zirconium Dioxide Powder: Preparation, Uses, and Safety

Zirconium Powder vs. Titanium Powder: Comparison of Properties and Applications