Both aluminum powder and alumina powder are important industrial materials. Although the two powders are written in a similar way, they are quite different in terms of appearance, properties, and applications.

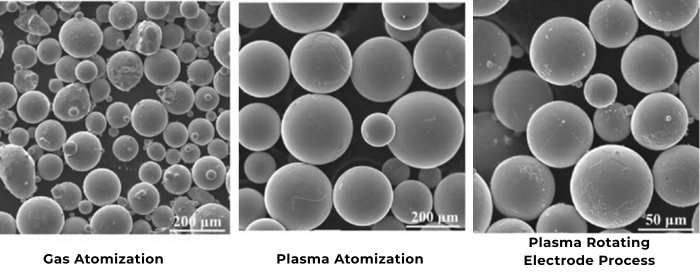

Aluminum powder is primarily composed of metallic aluminum (Al), which gives it a metallic luster, appearing silver-gray or silvery-white. The particles are generally fine and highly reflective, with various shapes like flakes, spherical forms, or irregular shapes.

Fig 1. Micro Aluminum Powder (Al)

On the other hand, alumina is a compound made of aluminum and oxygen, typically white or light gray. Alumina powder particles are fine and lack the metallic sheen, usually appearing as regular micron or nanometer-sized particles.

Fig 2. Aluminum Oxide Powder, Al2O3

Table 1. Table 1. Specific product details. Click on the products to visualize the difference.

|

Aluminum Powder |

Alumina Powder |

|

|

Properties are, therefore, different since aluminum powder and alumina are two entirely different materials.

Table 1. Comparison of physical and chemical properties of aluminum powder and alumina powder

.png)

One of the major constituents of aluminum powder is metallic aluminum, which has extremely high electrical and thermal conductivity while being highly chemically active. When exposed to air, aluminum powder easily oxidizes, creating a thin oxide film that creates some resistance to corrosion by preventing further oxidation of the material. This corrosion resistance will be limited both in acidic and alkaline media because strong acids or bases can destroy the oxide layer. It has a melting point of about 660°C; hence, it is suitable for application in processes and welding at low temperatures. Besides that, it has high reflectivity and thus finds use in reflective coatings and bright paints.

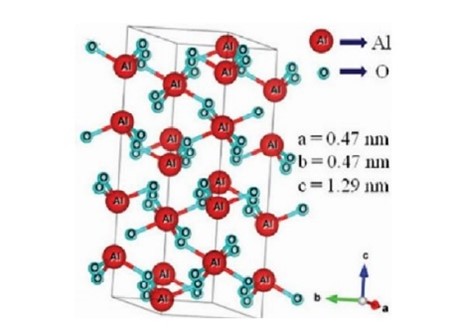

On the other hand, alumina is an oxide of extreme stability with strong chemical inertness, enabling it to stay stable under most corrosive conditions. The chemical structure makes it resistant to many acidic and basic media; hence, the possibility of a chemical reaction is reduced. The hardness of alumina is very high and has a Mohs hardness rating of 9, with very good wear resistance. It is one of the best choices for ceramic and wear-resistant coatings. Alumina also possesses a much higher melting point at around 2054°C, which could be suitable for high-temperature applications.

Fig 3. Crystalline structure of α- Al2O3

Overall, aluminum powder and alumina differ in composition, form, conductivity, and chemical activity, each playing a unique role in different industrial sectors.

Aluminum powder is widely used in powder metallurgy, fireworks manufacturing, and as a metallic luster additive in paints and plastics. It is also essential in the energy sector as a fuel.

Fig 4. Common uses of aluminum powders

On the other hand, alumina is primarily used in non-metallic applications as refractory materials, abrasives, ceramic raw materials, and catalyst carriers. Its applications are focused on high-performance ceramic and non-metal industries.

.png)

Fig 5. Common uses of aluminum oxide powders

In summary, aluminum powder and alumina powder are two different substances, and although they are related, their properties and uses differ greatly. Aluminum powder is mainly used for its metallic properties and reactivity, while alumina powder is used more for its stable chemical and physical properties.

Stanford Advanced Materials (SAM) is dedicated to the research and development of spherical powder technology. We supply a variety of 3D printing metal powders, refractory metal powders, titanium, aluminum, stainless steel, cobalt, chrome, nickel, copper, etc. If you are looking for high-quality additive manufacturing materials, please get a quote.