Micro titanium powder has diverse uses in traditional & high-tech industries like mechanics, electronics, aeronautics, metallurgy, chemistry, environment, etc.

Related products: Nano Titanium (Ti) Powder, Spherical Titanium Powder, Titanium Carbide Powder, Ferro Titanium Powder

Micro titanium powder has diverse uses in traditional & high-tech industries like mechanics, electronics, aeronautics, metallurgy, chemistry, environment, etc.

Related products: Nano Titanium (Ti) Powder, Spherical Titanium Powder, Titanium Carbide Powder, Ferro Titanium Powder

Experience the power of Micro Titanium (Ti) Powder, a groundbreaking material designed to revolutionize a wide range of industries. With its exceptional properties, this ultra-fine titanium powder opens up endless possibilities for innovation and advancement. Whether you're in aerospace, automotive, healthcare, or any other field that demands high-performance materials, Micro Titanium Powder is your key to unlocking the future.

|

CAS Number |

7440-32-6 |

|

Purity |

99.9% |

|

Chemical Formula |

Ti |

|

Morphology |

Nearly spherical |

|

APS |

325 mesh |

|

Melting Point (℃) |

1668 |

|

Boiling Point (℃) |

3260 |

|

Density (g/cm3) |

4.507 |

|

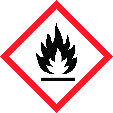

Signal Word |

Danger |

|

Hazard Statements |

H250 |

|

Hazard Codes |

P210-P231-P280-P302 + P334-P370 + P378-P422 |

|

Precautionary Statements |

P210-P280-P240-P241-P370+P378 |

|

Flash Point |

Not applicable |

|

Risk Codes |

N/A |

|

Safety Statements |

N/A |

|

RTECS Number |

N/A |

|

Transport Information |

UN1383- class 4.2 - PG 1- Pyrophoric metal, n-o.s., HI: all |

|

WGK Germany |

1 |

|

GHS Pictograms |

|