Aluminum oxide, commonly denoted by its chemical formula Al₂O₃, is an exceptionally important material. Its broad range of applications is due to its excellent physical, chemical, electrical, and optical properties. In particular, it has a profound impact on the application and development of optical coating technology.

You might not know the name, aluminum oxide. But we deal with this same material every single day. It has huge applications in optical coatings. Many items that accompany our routine, such as smartphones and eyeglass lenses or protective systems in aerospace, contain aluminum oxide.

1. Smartphone camera lens covers:

The material of the camera lens cover of many high-end smartphones is aluminum oxide. The material is perfect for camera lenses, where it needs to be optically transparent and hard as nails (which it could have been called if some ignoramus had not already claimed the sobriquet) so instead we have aluminum oxide. One example is the application of sapphire glass (monocrystalline aluminum oxide) in some iPhone models by Apple, which has been used to shield the camera lens as well as the Touch ID sensor.

2. Eyeglass Lenses:

To meet the intense hardness and wear-resistance requirements, optical surfaces are protected with a layer of aluminum oxide to prevent scratching or mechanical damage. Optical devices, in particular, require this, as it allows for sustained performance through repeated usage of the device over time.

3. LED Lighting:

Alumina is used on sapphire substrates in LED production. As the monocrystalline form of aluminum oxide, sapphire is characteristically transparent and has a high thermal conductivity that assists LEDs in maintaining stable efficient operation over an extended period.

4. High-End Watches:

Aluminum oxide (alumina) films protect the dials of high-end watches (e.g., Omega, Rolex), without scratching and wearing and also maintain good optical transparency as well as aesthetics.

5. Hard Disk Drives:

The read-write is actually a layer of aluminum oxide to the head disk drive as it has both very high speed and does not wear out, both sustainable characteristics with the current read/write performances.

6. Thermal Protection Systems:

Aluminum oxide is used in spacecraft thermal protection systems to protect them from high temperatures and oxidation during atmospheric re-entry. It provides excellent thermal stability and insulation properties.

7. Medical Implant Surfaces:

In this case, aluminum oxide is used to coat the surfaces of medical implants (for example artificial joints or bone fixation devices) to give biocompatibility and corrosion resistance needed for such applications that use materials that are stable within the body over long periods without causing adverse reactions.

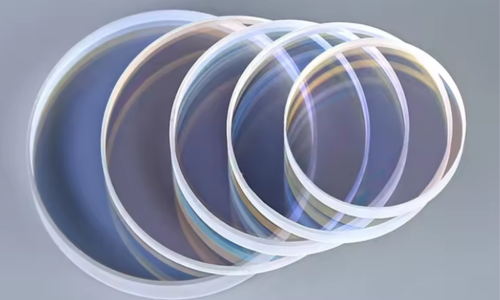

Fig 1. Manufacture Laser Protective Windows Laser Protection Lens

The extensive applications of aluminum oxide in optical coatings are because of its excellent properties.

Hardness: Aluminum oxide is very hard, with a Mohs hardness of about 9, second only to diamond and silicon carbide.

Melting Point: Aluminum oxide has a melting point of about 2072°C, giving it high thermal resistance.

Chemical Stability: Aluminum oxide is highly chemically stable at room temperature and pressure, making it resistant to reactions with acids, bases, and other chemical reagents.

Corrosion Resistance: Al₂O₃ has excellent corrosion resistance to many chemicals, remaining stable even in high-temperature environments.

Electrical Insulation: Al₂O₃ has very high resistivity, making it an excellent electrical insulator. At room temperature, its resistivity is about 10¹⁴ to 10¹⁵ Ω·cm.

Dielectric Constant: Al₂O₃ has a high dielectric constant, ranging from 9 to 10, making it suitable as a dielectric material in many electronic and electrical applications.

Breakdown Voltage: The high breakdown voltage of aluminum oxide films allows them to withstand high electric field strengths without electrical breakdown.

Transparency: Aluminum oxide is transparent in certain wavelength ranges, such as ultraviolet and visible light, making it suitable for optical applications.

Refractive Index: Aluminum oxide has a high refractive index, approximately 1.76 in the visible light range.

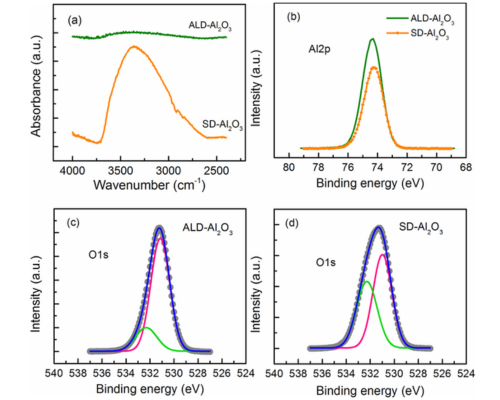

Fig 2. FT-IR and XPS spectra of aluminum oxide dielectrics[i].

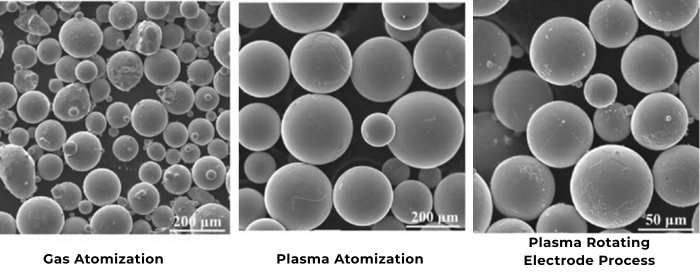

Stanford Advanced Materials (SAM) is at the forefront of metal powder development, offering high-performance and affordable alumina powders, for more information on alumina powders please feel free to get in touch and check out our home page.

These great properties make aluminum oxide have wide applications in optical coatings and exert a profound influence on the technological development of optical coatings.

1. Enhanced Durability and Scratch Resistance

Aluminum oxide, presented by the chemical symbol Al₂O₃, firstly, due to its hardness of a great degree, with a value of Mohs around 9, is consequently, in general, characterized for high scratch resistance and mechanical wear resistance. Once this quality is applied to optical coatings in severe high-wearing environments, smartphone camera lenses, eyeglasses, and watch faces come into existence. The durability, provided by coatings of aluminum oxide, enhances the lifetime of these optical components, maintaining their clarity and functionality across the length of the usage.

2. Improved Thermal Stability

Due to a high melting point, the temperature of aluminum oxide is approximately 2072°C; hence, it promises to be thermally stable. In reality, the coating can sustain a high temperature without losing its properties, marking the reliability of the optical coating in harsh environments.

3. Superior Chemical Resistance

Respectively, chemical stability, resistance to most chemicals, and corrosion on the part of aluminum oxide are highly regarded in the course of protecting the optical components from being chemically destructed. This, on the other hand, will cause no degradation of the coatings in the aluminum oxide in medical implants and industrial applications, not to mention affecting optical clarity and performance.

4. Improved transparency and optical clarity

Al₂O₃ is transparent in the ultraviolet and visible light spectrum; hence, it is an excellent material for optical coatings that should have maximum light transmission in the stated ranges. Ergo, it is important for applications like camera lenses, LED substrates, and other optical devices where light transmission is needed. The high refractive index of aluminum oxide also makes it suitable in boosting optical performance.

5. Excellent insulators for optical equipment

The high resistivity and dielectric constant of aluminum oxide make it an excellent insulator. This property gets quite useful in optical devices that may also use electrical currents or signals. For example, in some applications of LEDs and other electronic devices, Al₂O₃ coatings can provide an optical clarity, but at the same time also provide electrical insulation, which enhances the overall experience of the device.

6. Versatile Fabrication Techniques

Different types of fabrication techniques such as PVD, CVD, sol-gel, etc. can allow better control of thickness and homogeneity over aluminum oxide coatings. This versatility has paved the way for the development of high-grade optical coatings relevant for specific applications. Surface roughness and other coating properties can be controlled to ensure that the coating offers optimal performance for a wide variety of optical technologies.

Aluminum oxide (Al₂O₃) has many superior properties in optical coating technology. It significantly improves the performance and durability of optical devices and changes the application and development direction of optical coating technology. Therefore, it is rightly called a "game changer".

[i] Nayak, Pradipta & Caraveo-Frescas, J & Wang, Zhenwei & Hedhili, M. & Wang, Q & Alshareef, Husam. (2014). Thin Film Complementary Metal Oxide Semiconductor (CMOS) Device Using a Single-Step Deposition of the Channel Layer. Scientific reports. 4. 4672. 10.1038/srep04672.