Silicide powders are essential in various industries because of their unique properties and diverse applications. This guide delves into the world of silicide powders, exploring their properties and uses.

Silicide powders are binary compounds formed by the combination of silicon with certain metals such as lithium, calcium, magnesium, iron, chromium, etc. These powders show unique properties such as high melting points, excellent electrical and thermal conductivity, high hardness, and remarkable chemical stability. Common silicide powders include silicon carbide (SiC), titanium disilicide (TiSi₂), nickel silicide (NiSi), and iron silicon (FeSi).

1. High Melting Point

Silicide powders typically have very high melting points. For example, molybdenum silicon (MoSi₂) has a melting point of approximately 2030°C. This makes silicide powders suitable for high-temperature environments, such as high-temperature coatings and heating elements.

2. High Hardness

Silicide powders are known for their high hardness. For instance, silicon carbide (SiC) has a hardness close to that of diamond. This makes it highly applicable in abrasives, cutting tools, and wear-resistant components.

3. Electrical and Thermal Conductivity

Some silicides, such as NiSi and TiSi₂, exhibit excellent electrical and thermal conductivity. These properties make them suitable for use as contact materials and interconnects in electronic and electrical applications.

4. Corrosion Resistance

Silicide powders exhibit excellent corrosion resistance in high-temperature and corrosive environments. For example, MoSi₂ can form a protective oxide layer in oxidizing environments, enhancing its corrosion resistance.

5. Thermal Stability

Silicide powders possess good thermal stability, maintaining their mechanical properties and chemical stability at high temperatures. This makes them widely used in high-temperature structural materials and thermal barrier coatings.

6. Semiconductor Properties

Some silicides, such as silicon carbide (SiC), have wide bandgap semiconductor properties. They can be used in high-temperature, high-frequency, and high-power electronic devices, such as LEDs and power semiconductors.

.png)

Fig 1. Iron Silicon Powder (FeSi)

Silicide powders are widely and effectively used in anti-oxidation coatings, particularly in high-temperature and corrosive environments. Silicide powders, such as MoSi₂, can form a dense silicon dioxide (SiO₂) protective layer in high-temperature conditions. This protective layer effectively prevents the intrusion of oxygen and other corrosive gases, protecting the substrate material from oxidation. MoSi₂ anti-oxidation coatings are commonly used in high-temperature components in the aerospace, energy, and metallurgy industries, such as turbine blades, combustion chambers, and heating elements.

Additionally, silicide coatings show excellent corrosion resistance in high-temperature corrosive environments. Titanium silicon powder and chromium silicon powder can form stable protective layers in oxidative and corrosive media, extending the service life of materials. This makes them widely applicable in chemical equipment, petrochemical industries, and high-temperature heat treatment equipment.

.png)

Fig 2. Depiction of the formation and function of the protective silicon oxide layer1

Silicide powders, particularly NiSi and TiSi₂, are widely used in integrated circuit (IC) manufacturing. NiSi and TiSi₂ are widely used as interconnect materials. Because they have low resistivity and excellent thermal stability. Moreover, they can also maintain good electrical conductivity at high temperatures, which is crucial for signal transmission in integrated circuits.

Silicides are also used as contact materials in the source, drain, and gate contacts. Their good compatibility with silicon-based materials and low contact resistance help reduce contact resistance and enhance device performance.

Silicide powders, especially silicon carbide (SiC), are increasingly important in the semiconductor field because of their unique physical and chemical properties. Silicon Carbide (SiC) is widely used in high-temperature and high-power devices, such as SiC MOSFETs and SiC Schottky diodes. They can handle higher voltages and currents, improving system efficiency and reliability.

Silicon Carbide (SiC) also plays a crucial role in optoelectronics, such as blue and ultraviolet LEDs and photovoltaic devices. As a substrate material, SiC's high thermal conductivity and wide bandgap help improve LED efficiency and lifespan, as well as enhance photovoltaic conversion efficiency.

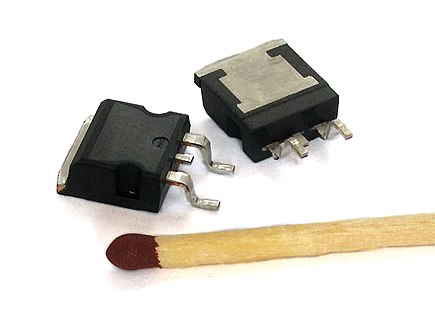

Fig 3. SiC MOSFETs

Tungsten silicide (WSi₂) and chromium silicide (CrSi₂) are utilized in wear-resistant coatings and components. Their high hardness and durability help extend the lifespan of tools and machinery parts subjected to intense wear and tear.

Some silicide powders, including iron silicon (FeSi), are used as catalysts in chemical reactions. Their catalytic properties enhance reaction rates and efficiency, particularly in processes involving hydrogenation and dehydrogenation.

Stanford Advanced Materials (SAM) is a premium supplier of metal powders, providing high-quality silicide powders at very competitive prices.

1. Iron Silicon Powder (FeSi): It’s an indispensable deoxidizer in the steelmaking industry.

2. Titanium Silicon Powder (TiSi): TiSi is valued for its high melting point and low resistivity, making it a preferred material for contacts and interconnects in semiconductor devices.

3. Silicon Nitride Powder (Si₃N₄): Si₃N₄ is a distinctive black-gray powder known for its importance as a key structural ceramic material. It boasts impressive properties such as high hardness, natural lubricity, and outstanding wear resistance.

4. Silicon Carbide Powder (SiC): SAM supplies high-purity silicon carbide powder in beta form. The purity of our alpha-phase silicon carbide powder can be 99.99%.

5. Nickel Silicide Powder (NiSi): NiSi is widely used in semiconductor technology due to its low resistivity and stable electrical properties. It plays a crucial role in modern integrated circuits.

In addition to the above, SAM also provides customers with Silicon Powder (SiO2) and Silica Powder with different particle sizes. If you want to know the difference between them, you can read this article: Silica and Silicon Powders: A Guide to Their Properties and Uses

Silicide powders, with their exceptional properties and versatile applications, are integral to advancements in electronics, high-temperature processing, wear-resistant materials, and energy solutions. Understanding these materials' unique characteristics and applications helps drive innovation across various industrial sectors. From basic principles to advanced uses, silicide powders continue to play a critical role in modern technology.

References:

1 Dworak, David & Banks, Bruce & Karniotis, Christina & Soucek, Mark. (2006). Evaluation of Protective Silicone/Siloxane Coatings in Simulated Low-Earth-Orbit Environment. Journal of Spacecraft and Rockets - J SPACECRAFT ROCKET. 43. 393-401. 10.2514/1.15787.

United States

.png)