Manganese (Mn) is a silvery-white metal that, when processed into powder, appears silver-gray. It is hard and brittle but easily oxidizes in air, forming a brown oxide coating. Upon heating, it oxidizes more rapidly, creating a layered rust-like film. Manganese powder, though seemingly ordinary, is an indispensable material in many industrial processes.

The preparation of manganese powder involves various methods, including mechanical crushing, chemical reduction (e.g., aluminothermic or hydrogen reduction), and traditional thermal smelting followed by grinding. These methods typically produce Mn powder with lower purity, suitable for applications where high purity is not critical.

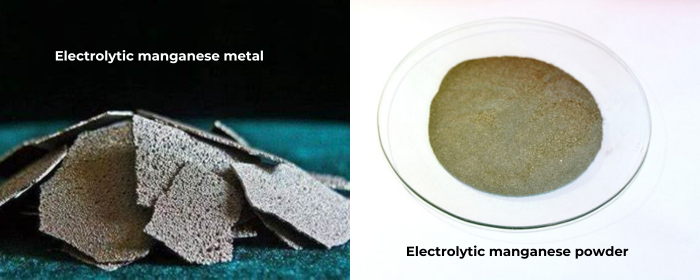

Electrolytic manganese powder, on the other hand, offers higher purity. It is produced by crushing and sieving electrolytic manganese (usually in flake form). The electrolytic process removes most impurities, resulting in manganese powder with a purity of 99.7% to 99.9% or higher.

Fig 1. Electrolytic manganes

Manganese powder, as an essential metallic material, has a wide range of applications. From the steel industry to the battery sector, from the chemical field to various other domains, manganese powder plays an indispensable role.

Steel is the cornerstone of modern industry, and manganese powder is an essential element in steel production. Its primary functions include deoxidation, desulfurization, and alloying.

Deoxidation is a critical step in steel production. Manganese powder reacts with oxygen in molten steel to form stable oxides, reducing oxygen content and improving steel quality. Excess oxygen in steel can decrease its toughness and plasticity, leading to defects like cracks. Adding manganese powder effectively removes oxygen, stabilizing the steel's performance.

Secondly, desulfurization is another important function of manganese powder. Sulfur is a harmful element in steel, as it reduces the toughness and weldability of the material. Manganese powder reacts with sulfur in steel to form manganese sulfide, thereby reducing the sulfur content. Through desulfurization, the quality of the steel can be improved, making it more suitable for various industrial applications.

In addition, Mn powder can be added to steel as an alloying element to enhance its strength, hardness, and wear resistance. Different manganese contents impart varying properties to the steel. For example, high-manganese steel exhibits exceptional hardness and wear resistance, making it widely used in mining and engineering machinery. On the other hand, low-manganese steel offers better toughness and weldability, making it suitable for construction structures and automotive manufacturing.

For example:

• Mid-carbon Ferro Mn Powder / MC-FeMn Powder

• High Carbon Ferro Manganese (FeMn) Powder

With the rapid development of new energy technologies, the demand for manganese powder in the battery industry is steadily increasing. Its primary application in batteries is as a key component of cathode materials.

In lithium-ion batteries, Lithium manganese oxide (LMO, LiMn2O4, BE-30) is a common cathode material. Lithium manganese oxide is widely used in electric tools and electric bicycles due to its high voltage platform, excellent safety, and low cost. Manganese powder, as a raw material for Lithium manganese oxide, directly impacts the quality and performance of the battery.

Manganese powder is also used to produce other battery types, such as nickel-manganese batteries and zinc-manganese batteries. These batteries have specific advantages in different applications. For example, nickel-manganese batteries feature high energy density and long cycle life, suitable for high-end electronic products, while zinc-manganese batteries are cost-effective and safe, commonly used in small household appliances.

Fig 2. Lithium manganese oxide batteries

Manganese powder finds extensive use in the chemical industry. It acts as a catalyst in organic synthesis reactions. Manganese catalysts are efficient and environmentally friendly, improving reaction selectivity and yield while reducing production costs.

Manganese powder is also used to produce various manganese compounds, such as manganese dioxide and potassium permanganate. Manganese dioxide is a critical oxidant used in batteries, ceramics, and glass, while potassium permanganate is a strong oxidizing agent used for disinfection and water treatment.

Beyond the industries mentioned above, manganese powder holds potential value in other fields.

• Environmental protection: Mn powder can be used in wastewater treatment to remove heavy metal ions and organic pollutants.

• Agriculture: It serves as a trace element fertilizer, enhancing crop yield and quality.

With continuous technological advancements and the expansion of application fields, the uses of manganese powder are expected to become even more extensive. Stanford Advanced Materials (SAM) is a global leading supplier of spherical metal powders, with over twenty years of experience in manufacturing and selling manganese based powders. If you would like to learn more about titanium alloy powders, we recommend visiting Manganese for more information.

United States

.png)