Iron powder (Fe powder) is an essential industrial raw material that plays a critical role in metallurgy, chemical engineering, electronics, and manufacturing. It is the most widely used and consumed metal powder in the powder metallurgy industry, accounting for about 70-80% of the total metal powder consumption in this field. Without exaggeration, the absence of Fe powders would impose significant limitations on materials and processes in industrial production.

Industrial-grade iron powder primarily includes reduced iron powder and atomized iron powder, named after their production methods. To meet broader industrial needs, other types of Fe powders produced by alternative methods are also widely used. Among these, electrolytic iron powder and carbonyl iron powder are the most prominent.

The advantage of reduced iron powder lies in its sponge-like, complex particle morphology, which offers excellent forming performance and green strength. However, the bulk density of Fe powder produced by this method is relatively low, making it suitable for medium- and low-density powder metallurgy parts and oil-impregnated bearings.

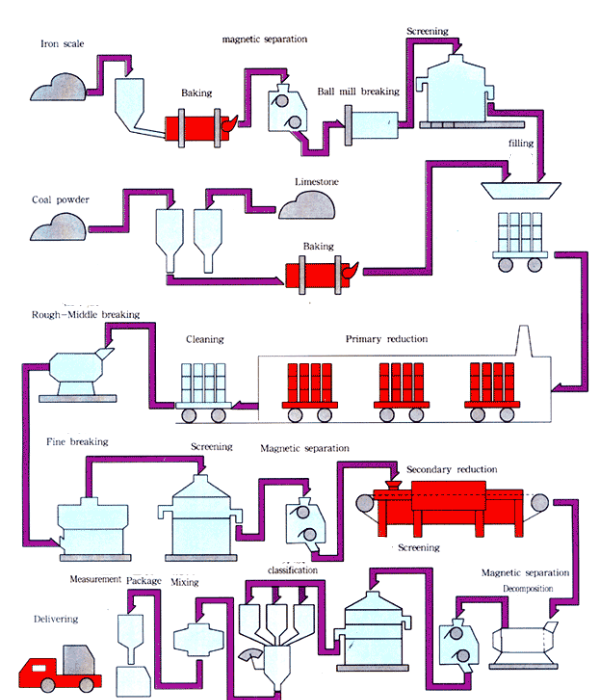

Fig 1. Preparation process of reduced Fe powder, Image source: cnpowder.com

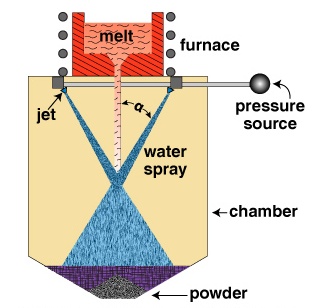

Water-atomized iron powder features near-spherical, non-porous particles with high bulk density. Although its forming ability is slightly inferior, it easily produces high-density pressed parts during forming. Typically, medium- and high-density powder metallurgy parts are manufactured using water-atomized Fe powder.

Fig 2. Principle of water atomized Fe powder production (Source: Metal Powder Industry Federation)

Electrolytic iron powder is characterized by its extremely high purity and fine particle structure. Unlike the porous morphology of reduced Fe powder and the high-density nature of atomized Fe powder, electrolytic Fe powder is prepared via electrolysis, resulting in dendritic or flaky particles. This unique morphology endows it with excellent chemical activity and compressibility. With a purity of over 99%, electrolytic Fe powder is widely used in manufacturing high-end powder metallurgy products, such as precision components. Additionally, it is extensively applied in electromagnetic shielding materials and chemical catalysts.

Carbonyl iron powder is distinguished by its high purity and uniform particle shape. Produced via the carbonyl method, its particles are spherical or near-spherical, with extremely small sizes, typically in the micron or sub-micron range. This production method gives carbonyl iron powder excellent flowability and magnetic properties. Due to its high purity, uniform particle size, and strong surface activity, carbonyl Fe powder is widely used in magnetic materials (e.g., magnetic cores and soft magnetic alloys), metal injection molding (MIM), and electronic component manufacturing. It also plays an important role in coatings, lubricant additives, and high-performance wave-absorbing materials.

Table 1. Comparison of Fe Powders Prepared by Different Methods

|

Type |

Production Method |

Particle Shape |

Purity |

Bulk Density |

Application Fields |

|

Reduced Fe Powder |

Oxide Reduction |

Irregular Shape |

High |

Medium; |

Powder metallurgy; |

|

Atomized Fe Powder |

Gas Atomization; |

Near-Spherical |

High |

High |

3D printing; |

|

Electrolytic Fe Powder |

Electrolysis |

Dendritic; |

Very High |

Low |

High-end component manufacturing; |

|

Carbonyl Fe Powder |

Carbonyl Method |

Spherical; |

Very High |

Medium; |

Magnetic materials; |

Iron powder holds significant value across many industries.

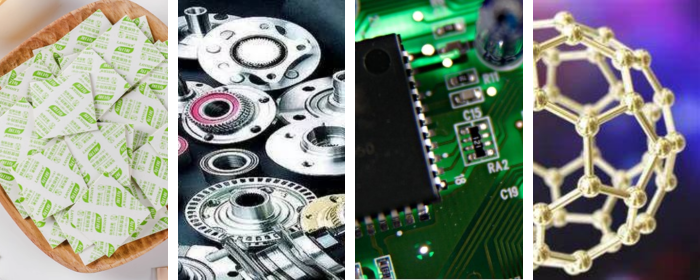

Firstly, iron powder can be used to produce various mechanical parts such as gears, bearings, cams, and cutting tools. This is what we commonly refer to as powder metallurgy. Components made from Fe powder using powder metallurgy processes are employed in various industries. Among these, the automotive industry is one of the largest application fields for Fe powder. It is used to manufacture engine, transmission, and steering system parts.

Apart from powder metallurgy, another major application of Fe powder is as catalysts and reducing agent. In chemical synthesis, Fe powder can act as a catalyst to accelerate reaction speeds; in wastewater treatment, it can serve as a reducing agent to remove harmful substances from water. Based on these principles, the application of Fe powder in environmental protection is also increasing, such as in heavy metal removal, wastewater treatment, and air purification.

Iron powder is also used in the field of electromagnetic materials, such as for manufacturing electromagnetic shielding materials and magnetic recording media. Its high magnetic permeability and low coercivity make it an essential raw material for high-performance electromagnetic materials.

A common application of iron powder in food is placing small packets of Fe powder in packaging bags. Utilizing the oxidation property of iron, these packets function as oxygen absorbers, significantly preserving and protecting food. Fe powder and ferrous salts also serve as food antioxidants and nutritional fortifiers, with widespread addition to powdered milk.

United States

.png)