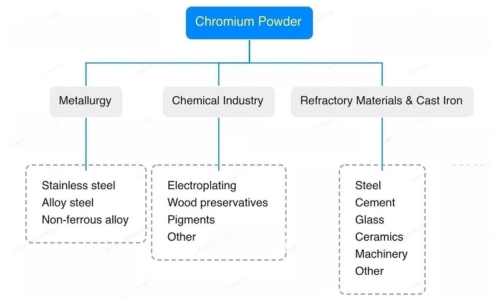

Due to its excellent properties, such as hardness, brittleness, and corrosion resistance, chromium is widely used in metallurgy, chemical industry, cast iron, refractory materials, and high-tech fields.

Chromium, with the chemical symbol Cr, belongs to Group VIB of the periodic table. Its atomic number is 24, atomic weight is 51.996, density is 7.19 g/cm³, melting point is 1857±20°C, and boiling point is 2672°C. It has a body-centered cubic crystal structure and common oxidation states of +3, +6, and +2, with an ionization energy of 6.766 eV.

Chromium powder is a fine powder material made from metallic chromium through mechanical pulverization or atomization. Metallic chromium is extremely hard and brittle, with excellent corrosion resistance. It is an inert metal, stable to oxygen and moisture at room temperature. Chromium can form compounds of various colors, such as metallic chromium, which is silvery and shiny, chromium sulfate, which is green, and magnesium chromate, which is yellow.

Fig 1. Chromium powder uses

In the metallurgical industry, chromium powder is a key raw material for producing stainless steel and heat-resistant alloys. Adding chromium significantly enhances the corrosion resistance, hardness, and oxidation resistance of alloys. For instance, stainless steel typically contains 10%-20% chromium to improve its rust resistance. When exposed to corrosive substances, stainless steel forms a fine and firm chromium oxide film on its surface, protecting the internal metal from further corrosion. Some stainless steels can maintain excellent properties even at high temperatures of 800°C.

Fig 2. Chromium-manganese series stainless steel: the role of chromium in stainless steel

Chromium powder is used to create metal coatings with high corrosion resistance, particularly for parts exposed to high humidity, acidic, or alkaline environments. The chemical inertness of chromium helps form a protective oxide layer, effectively preventing substrate corrosion. Additionally, chromium powder is used to produce hard coatings to enhance the surface hardness and wear resistance of materials. It is also a fundamental material for decorative coatings in electroplating processes.

Fig 3. Chrome-plated parts

Chromium powder is widely utilized in the chemical industry for producing various chemical products, such as chromates and chromium pigments. These compounds play vital roles in catalysts, coatings, electroplating, and dyes. For example, hexavalent chromium compounds are essential raw materials for high-efficiency catalysts, promoting various chemical reactions efficiently.

Due to its high melting point and oxidation resistance, chromium powder is extensively used to produce advanced refractory materials, such as chrome-magnesia bricks and chrome-alumina bricks. These materials are often used in high-temperature furnaces, smelting kilns, and other extreme environments, effectively extending the service life of the equipment.

In cast iron production, adding an appropriate amount of chromium powder can improve the mechanical properties of iron-based materials, primarily by enhancing wear resistance and ductility. This is because chromium powder forms stable carbide structures, strengthening the cast iron's durability and toughness, making it especially suitable for manufacturing mechanical components and tools.

With its exceptional properties, chromium powder plays a crucial role in metallurgy, chemical industry, refractory materials, and cast iron applications. As technology continues to advance, its potential in emerging fields such as 3D printing, functional coatings, and new energy technologies is gradually being explored. It is foreseeable that chromium powder will play an increasingly vital role in future industrial manufacturing, contributing to sustainable development across various industries.

Founded in 1994, Stanford Advanced Materials (SAM) is committed to providing first-class atomized metal alloy powders to customers in the commercial and industrial fields. SAM can provide you with Spherical Chromium Powder with a particle size of 45-150 um. If you are interested in other chromium alloy powders, welcome to Get A Quote.

|

Type |

Purity |

Shape |

Particle Size |

|

99.50% |

Spherical |

45-150 um |

|

|

99.8% - 99.95% |

Irregular |

-325 mesh, 1-5 micron or other sizes |

|

|

99.90% |

Irregular |

50nm |

|

|

≥99.8% |

Irregular |

|

|

|

|

Irregular |

-60 mesh ~ -200 mesh |

|

|

|

Irregular |

-100 mesh |

|

|

>99.5% |

Irregular |

-325 mesh |

United States

.png)