Tungsten powder is a key raw material in powder metallurgy processes, used to produce high-density and high-strength tungsten-based materials. On this basis, it plays an important role in electronics, aerospace, chemical engineering, and medical fields.

Tungsten (W) powder is the powdered form of metallic tungsten. To some extent, tungsten powder inherits the properties of tungsten. Some kinds of tungsten powder, such as some tungsten alloy powders, can realize even better performance by incorporating other elements.

Tungsten has a density of about 19.25g/cm2, which makes it one of the densest metals. It is also the metal with the highest melting point. Tungsten powder exhibits high hardness and high tensile strength, especially tungsten alloy materials prepared through powder metallurgy processes, which have excellent wear resistance and mechanical strength. Although tungsten's electrical and thermal conductivity are inferior to copper, it can still maintain stable electrical and thermal performance at high temperatures.

Tungsten powder is highly brittle at room temperature and liable to break. This limits the mechanical uses of the pure metal at room temperature, but alloying or compounding with other metals can enhance toughness and impact resistance.

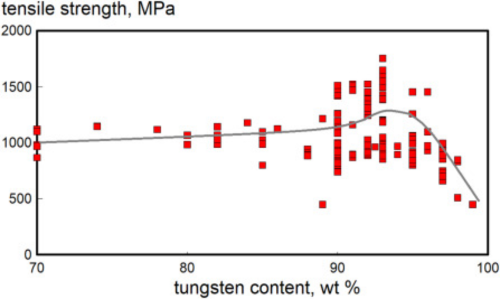

Fig 1. The tensile strength of tungsten can reach 1039 MPa[i]

Tungsten powder has different particle sizes and morphologies, which are usually spherical, needle-like, and irregular shapes. Different particle sizes and morphologies have different flowabilities, compressibilities, and sintering performances in different processes. Fine-grained tungsten powder is suitable for the preparation of high-density materials, while coarse-grained tungsten powder is suitable for applications requiring larger porosity.

Tungsten and its powders have excellent corrosion resistance in most acidic, alkaline, and saline solutions. Tungsten powder is highly chemically stable at room temperature and exhibits low reactivity with most chemical reagents.

Although tungsten as a material has low weldability, through the processes of powder metallurgy, high-quality materials based on tungsten with good processing performance can be prepared. In particular conditions, tungsten and its powders show good biocompatibility, enabling their application in the manufacture of medical devices and implants.

The production of tungsten powder and tungsten alloy powders involves various process methods, each with different characteristics and applicable ranges. We have compiled the main preparation methods currently available and compared their applicability.

Preparation Methods for Pure W Powder:

|

Method |

Principle |

Advantages |

Disadvantages |

|

Hydrogen Reduction |

Reducing tungsten oxide at high temperatures in a hydrogen atmosphere to generate pure W powder |

High purity, uniform particles |

High equipment requirements, higher cost |

|

Decomposing gas-phase tungsten sources at high temperatures to deposit tungsten powder |

Fine particle size, controllable morphology |

Complex process, high cost |

|

|

Plasma Spheroidization |

Melting tungsten metal droplets with plasma and rapidly solidifying to form spherical powder |

Regular particle shape, good flowability |

High energy consumption, large equipment investment |

|

Mechanical Reduction |

Converting tungsten oxide to tungsten powder through mechanical methods in the presence of a reducing agent |

Lower cost, suitable for large-scale production |

Slightly lower purity and particle morphology |

|

Method |

Principle |

Advantages |

Disadvantages |

|

Mechanical Alloying |

Thoroughly mixing and grinding tungsten powder with alloy element powders through mechanical ball milling, promoting atomic-level diffusion and alloying |

Uniform alloy distribution, wide applicability |

Time-consuming production process, high equipment wear |

|

Melting-Fraction |

Melting tungsten with alloy elements to form molten alloy, then rapidly cooling and pulverizing into powder |

Controllable alloy composition, suitable for large-scale production |

High energy consumption for melting, possible uneven distribution of alloy elements |

|

Combustion Reduction |

Simultaneously reducing and alloying tungsten oxide with a metal reducing agent in a combustion reaction to generate tungsten alloy powder |

Rapid reaction, high production efficiency |

Difficulty in controlling powder particle size and morphology |

|

Gas Phase Deposition |

Using chemical vapor deposition technology to simultaneously deposit gaseous precursors of tungsten and alloy elements to form alloy powder |

Controllable particle size and composition, suitable for high-precision applications |

Complex process, high cost, strict equipment requirements |

Each method has its advantages and disadvantages. Therefore, when considering which preparation method to choose, it is necessary to combine the specific application requirements of the product, cost control, and performance requirements.

Tungsten powder is widely used in multiple fields due to its excellent physical and chemical properties.

Tungsten powder is a key raw material for manufacturing tungsten-based alloys. Known for their high density and exceptional wear resistance, these alloys are widely used in industrial cutting tools such as drill bits and milling cutters. Additionally, tungsten powder is utilized in manufacturing electrodes and high-temperature electronic components, benefiting from its excellent electrical conductivity and thermal stability. Its versatility also extends to aerospace and automotive applications, where durability and performance under extreme conditions are essential.

Through powder metallurgy technology, tungsten powder can be processed into tungsten wires and tungsten rods. These are the main materials used in everyday incandescent lamp filaments and arc welding electrodes.

The high atomic number of tungsten powder helps generate high-intensity X-rays, making it suitable for manufacturing electrodes in electronic tubes, fluorescent lamp electrodes, and targets in X-ray tubes.

In the medical field, tungsten powder is used to manufacture radiation shielding materials and high-density medical implants, such as artificial joints and dental instruments, providing the necessary hardness and wear resistance.

Tungsten powder has excellent physical and chemical properties and is an indispensable material in many industries. Stanford Advanced Materials (SAM) provides tungsten powder and tungsten-based powders of different particle sizes and purity.

[i] Randall M. German, Sintered tungsten heavy alloys: Review of microstructure, strength, densification, and distortion, International Journal of Refractory Metals and Hard Materials, Volume 108, 2022, 105940, ISSN 0263-4368, https://doi.org/10.1016/j.ijrmhm.2022.105940

United States

.png)