Surface wear-resistant coatings are essential for extending the lifespan and performance of industrial components operating under harsh conditions. Alloy powders, known for their exceptional durability, hardness, and resistance to wear and corrosion, are among the most effective materials for these coatings. In this blog, we will explore the top six alloy powders commonly used for surface wear-resistant repair coatings.

.png)

Fig 1. Top 6 Alloy Powders Used for Surface Wear-Resistant Coating

Tungsten Carbide-Cobalt (WC-Co) alloy powder is a popular choice for wear-resistant coatings. Known for its remarkable hardness and toughness, WC-Co is extensively used in industries where components are subjected to extreme wear and tear, such as mining, oil and gas, and metalworking.

WC-Co coatings offer several key benefits. Their exceptional hardness makes them incredibly resistant to abrasive wear, significantly extending the lifespan of coated components. Despite this hardness, WC-Co maintains good toughness, allowing it to withstand impact and shock loads effectively. Additionally, the cobalt binder enhances the coating's corrosion resistance, making it suitable for use in harsh environments.

These properties make WC-Co alloy powder ideal for various applications. It is commonly used in drill bits and cutting tools within the mining industry, where durability is paramount. In the oil and gas sector, WC-Co is applied to valve seats and seals to ensure long-lasting performance. Moreover, the metalworking machinery industry utilizes WC-Co for wear parts, benefiting from the material's exceptional hardness and resistance to wear and corrosion.

As a well-known metal powder supplier, Stanford Advanced Materials (SAM) provides high-quality WC-Co Spherical Powder:

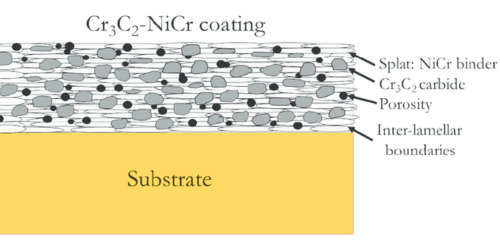

Chromium Carbide-Nickel Chromium (Cr3C2-NiCr) alloy powder is renowned for its excellent wear and corrosion resistance, particularly at high temperatures. This makes it a preferred material for coatings in high-temperature environments.

Cr3C2-NiCr coatings provide excellent high-temperature stability, retaining their hardness and wear resistance even at elevated temperatures. The presence of nickel-chromium enhances the oxidation resistance of the coating, preventing degradation in oxidizing atmospheres. Additionally, chromium carbide offers exceptional wear resistance, making the coating suitable for abrasive conditions.

These attributes make Cr3C2-NiCr alloy powder suitable for various high-temperature applications. It is used in combustion chambers and turbine components in the aerospace industry, where high-temperature stability is crucial. In industrial processes involving high temperatures, Cr3C2-NiCr is applied to furnace rolls and other components. Additionally, hydraulic cylinders and pistons benefit from the wear-resistant properties of Cr3C2-NiCr coatings.

Fig 2. Schematic view of a typical Cr3C2-NiCr coating used in wear-corrosion applications.[1]

Nickel-Aluminum Bronze (Ni-Al-Bronze) alloy powder is widely used for wear-resistant coatings in marine and industrial applications. Its excellent combination of strength, toughness, and corrosion resistance makes it ideal for harsh environments.

Ni-Al-Bronze coatings provide excellent corrosion resistance, particularly in seawater environments, making them ideal for marine applications. The alloy also offers good wear resistance, ensuring longevity in abrasive conditions. Furthermore, Ni-Al-Bronze maintains high strength and toughness, even in demanding environments.

These characteristics make Ni-Al-Bronze alloy powder ideal for a range of applications. In marine vessels, it is used for propeller blades and shafts due to its corrosion resistance and durability. Seawater handling systems benefit from Ni-Al-Bronze in pump components and valves. Additionally, the alloy is utilized in heavy machinery for bearings and bushings, where strength and toughness are essential.

.png)

Fig 3. Ni-Al-Bronze coatings

Stellite alloy powder, a family of cobalt-based alloys, is known for its outstanding wear and corrosion resistance. These alloys are widely used in applications where components are subjected to extreme wear, heat, and corrosion.

Stellite coatings are known for their superior wear resistance, making them highly resistant to abrasive and adhesive wear. They maintain their hardness and wear resistance at high temperatures, providing excellent heat resistance. Moreover, Stellite alloys offer exceptional corrosion resistance and oxidation protection.

These properties make Stellite alloy powder suitable for a variety of demanding applications. It is commonly used in internal combustion engines for valve seats and stems due to its wear resistance. In the metalworking industry, Stellite is applied to cutting tools and dies. Additionally, high-temperature environments benefit from Stellite in bearings and bushings, where both wear and heat resistance are crucial.

.png)

Fig 4. Cross-section of the laser remelted Stellite 6 coatings[2]

Iron-based alloy powders are a versatile and cost-effective option for wear-resistant coatings. These alloys can be tailored to provide a balance of hardness, toughness, and corrosion resistance, making them suitable for a wide range of applications.

Iron-based alloy powders offer a cost-effective solution for wear-resistant coatings. These alloys can be customized to provide a balance of hardness, toughness, and corrosion resistance, making them versatile for various applications. They offer a good balance of wear and corrosion resistance.

Iron-based alloy powder is widely used in agricultural and construction machinery for wear-resistant coatings. Mining equipment and tools benefit from the hardfacing provided by iron-based alloys. Additionally, industrial components that require repair and restoration utilize iron-based alloy powders for enhanced durability and performance.

Carbon-Chromium-Boron (C-Cr-B) alloy powder is a unique material known for its excellent wear resistance and high hardness. The combination of carbon, chromium, and boron results in a powder that provides robust performance in challenging environments.

C-Cr-B coatings offer high hardness due to the presence of carbon and boron, making them extremely resistant to wear. Chromium enhances the corrosion resistance, protecting the coated surfaces from oxidation and other corrosive processes. Additionally, C-Cr-B coatings maintain their properties at high temperatures, ensuring durability in hot operating conditions.

These benefits make C-Cr-B alloy powder ideal for hardfacing cutting tools and dies. The mining and drilling equipment industry utilizes C-Cr-B for wear-resistant coatings. Furthermore, industrial machinery exposed to abrasive conditions benefits from the surface repair capabilities of C-Cr-B coatings.

Tips: Stanford Advanced Materials (SAM) offers fully alloyed C-Cr-B powders.

The use of alloy powders for surface wear-resistant repair coatings is essential for enhancing the durability and performance of industrial components. Each of the alloy powders discussed—Tungsten Carbide-Cobalt (WC-Co), Chromium Carbide-Nickel Chromium (Cr3C2-NiCr), Nickel-Aluminum Bronze (Ni-Al-Bronze), Stellite, Iron-Based Alloys, and Carbon-Chromium-Boron (C-Cr-B)—offers unique advantages tailored to specific applications and operating conditions.

Choosing the right alloy powder depends on several factors, including the operating environment, the type of wear and corrosion expected, and the specific requirements of the application. By selecting the appropriate alloy powder, industries can significantly extend the life of their components, reduce downtime, and improve overall efficiency.

As technology advances, we can expect further innovations in alloy powder compositions and coating techniques, leading to even more robust and durable wear-resistant coatings. Whether in aerospace, marine, mining, or manufacturing, the continued development of alloy powder coatings will play a crucial role in driving industrial progress and sustainability.

[1] Sadeghi, Esmaeil. (2016). Corrosion Behavior of HVAF-Sprayed Bi-Layer Coatings.

[2] Relu, Ciubotariu & Frunzaverde, Doina & Marginean, Gabriela & Serban, Viorel-Aurel & Bîrdeanu, Aurel - Valentin. (2016). Optimization of the laser remelting process for HVOF-sprayed Stellite 6 wear resistant coatings. Optics & Laser Technology. 77. 98-103. 10.1016/j.optlastec.2015.09.005.

United States

.png)