Titanium alloys are widely used in fields such as aerospace and medical devices. Among the numerous titanium alloys, TC4 titanium alloy and Grade 5 titanium alloy are often mentioned. They are actually the same type of titanium alloy material.

TC4 titanium and Grade 5 titanium are essentially different naming conventions for the same titanium alloy, Ti-6AL-4V. TC4 is the designation for a titanium alloy under the Chinese National Standard (GB), while Grade 5 is the designation for the same titanium alloy under the American Society for Testing and Materials (ASTM). Both have essentially identical chemical compositions and properties, belonging to the titanium-aluminum-vanadium alloy category.

Chemical Composition:

Due to the high consistency in chemical composition and structure, TC4 titanium can be directly used in engineering applications as ASTM Grade 5 titanium.

The grades Titanium Grade 1 to Grade 12 are based on the American ASTM standards, and their corresponding Chinese grades are as follows:

Table 1. Titanium Alloy Grade Comparison Table

.png)

Whether TC4 or Grade 5, their composition is Ti-6Al-4V, which is a high-performance material with high strength and excellent corrosion resistance. Ti-6Al-4V is also the most maturely applied titanium alloy material.

The main chemical components of TC4 titanium include Titanium (Ti), Aluminum (Al), Vanadium (V), and Iron (Fe). Among them, the titanium content is over 90%, aluminum content is about 6%, vanadium content is 4%, and iron content is low, generally not exceeding 0.3%. This specific formulation gives TC4 titanium alloy excellent mechanical properties and corrosion resistance.

In terms of mechanical properties, Ti-6Al-4V titanium alloy performs exceptionally well. Its tensile strength can reach over 1000 MPa, with yield strength around 900 MPa, and it possesses high hardness and elastic modulus.

TC4 titanium also exhibits excellent corrosion resistance. Its corrosion resistance is mainly reflected in its ability to withstand corrosive media such as oxidation, nitration, and chlorination. In corrosive environments like seawater or chemical industries, TC4 titanium alloy can maintain surface smoothness and mechanical properties for a long time, ensuring a longer service life.

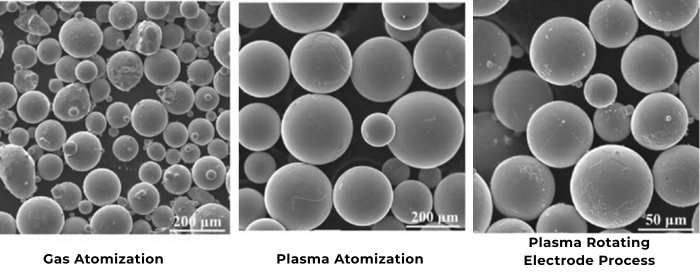

TC4 titanium powder (Ti-6AL-4V) is a powdered material prepared from TC4 titanium through methods such as gas atomization, water atomization, or plasma spraying. It is the ideal material for 3D printing.

This is mainly due to the multiple advantages of Ti-6Al-4V powder:

Traditional aircraft designs are limited by conventional manufacturing technologies, resulting in the "design achievable, but not manufacturable" problem for some innovations. The development of 3D printing technology provides an opportunity to realize the manufacturing of complex and innovative structures. TC4 powder, with its high strength-to-weight ratio and corrosion and high-temperature resistance, becomes an ideal material.

.png)

Fig 1. Titanium aerospace components

Titanium alloy, as a hotspot material for biomedical implants, is applied in medical fields such as artificial joints, vascular stents, and orthopedic instruments. TC4, as a commonly used biomedical titanium alloy, has been applied in clinical settings in China. Traditional titanium alloy processing methods involve casting, which is complex, has poor precision, high costs, and pollutes the environment. Currently, with the help of 3D printing technology, TC4 titanium alloy powder is being applied in more fields:

.png)

Fig 2. 3D printed titanium alloy sternum and rib cage

Especially in the field of orthopedics, porous titanium alloy's corrosion resistance, biocompatibility, and mechanical properties that match human bone make it an ideal orthopedic implant substitute. The uniquely designed porous structure and rough inner and outer surfaces of porous titanium materials facilitate the adhesion, proliferation, and differentiation of osteoblasts, promoting new bone tissue growth and helping to form an integrated interface between the implant and bone.

Stanford Advanced Materials (SAM) is a global leading supplier of 3D printing powders, with over twenty years of experience in manufacturing and selling titanium alloy powders. If you would like to learn more about titanium alloy powders, we recommend visiting Titanium Based Powder for more information.