Particle size and particle size distribution (PSD) are fundamental parameters of metal 3D printing powder and have a direct impact on powder flowability, layer homogeneity, printing accuracy, and overall part performance.

Beginners in metal powders might confuse these three similar concepts, but they are easy to distinguish:

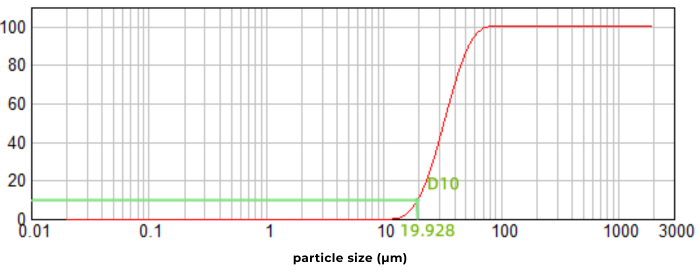

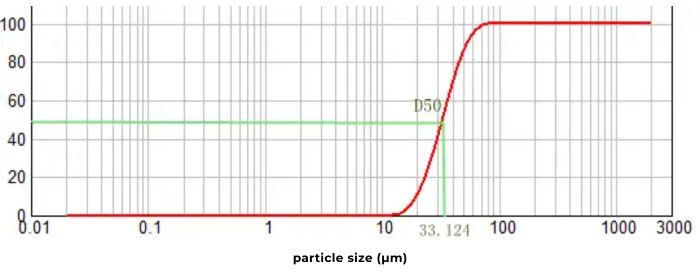

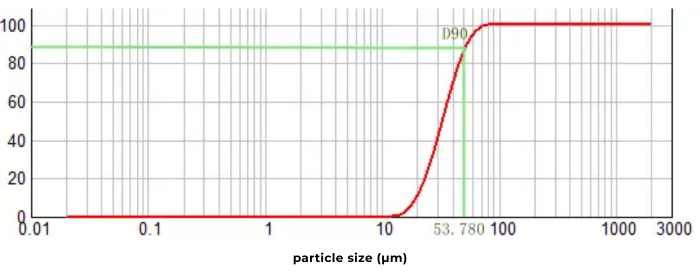

D10, D50, and D90 are three crucial parameters of particle size distribution, illustrating the distribution characteristics at diverse ranges of particle size.

D10 is the particle size at the 10% cumulative distribution fraction. It is a physical term referring to 10% of the particles being less than or equal to this size. D10 is commonly used to indicate the fine end of a powder's particle size range.

D50, or median particle size, is the particle size at the 50% cumulative distribution point. That is, 50% of the particles are larger than this value, and 50% of the particles are smaller. For example, a sample with D50 = 33.124μm indicates that 50% of particles are bigger than 33.124μm and 50% smaller. D50 is usually used to define the mean particle size of a powder.

D90 is the particle size at the 90% point of the cumulative distribution. That is, 90% of the particles are smaller, and 10% are larger. It is commonly used to characterize the range of large particles in a powder and is a critical parameter for powder making and application. Similarly, D95 or D97 are used in various industries, and both have the same physical significance as D90.

Traditional powder metallurgy uses powders ranging from 0-150μm. However, different 3D printing methods require different particle ranges, as shown in Table 1.

Laser Powder Bed Fusion (SLM/DMLS) employs powder between 15-63μm, though 20-53μm is typical. Utilization of finer powders guarantees better layer flatness and high-definition printing, with superior part density and polished surface finish. Fine powders can, however, produce flowability problems, and SLM therefore requires very tight sphericity and PSD control, normally with narrow PSD and D50 at 30-40μm.

In contrast, Electron Beam Melting (EBM) uses coarser powders (45-106μm) due to the higher energy electron beam. The higher particles increase flowability and facilitate the high preheating requirements of the process.

Binder Jetting provides greater size flexibility requirements (10-100μm), compromising layer spreading and sintering density.

Directed Energy Deposition (DED/LMD) prefers coarse powders (50-150μm) to allow stable powder feeding without clogging. DED also needs good flowability, with high sphericity and surface smoothness.

Table 1. Particle Size Ranges for Different Processes

|

Process |

Size Range (μm) |

Key Requirements |

Common Materials |

|

SLM/DMLS |

15-63 |

Fine powder, narrow distribution (Span <1.5), high sphericity, low oxygen |

316L Stainless Steel, Ti6Al4V, AlSi10Mg |

|

EBM |

45-106 |

Coarser powder, prioritized flowability, suited for high-energy beam |

Ti6Al4V, CoCr Alloys |

|

Binder Jetting |

10-100 |

Wider distribution acceptable, balances spreading and sintering density |

420 Stainless Steel, Tool Steel |

|

DED/LMD |

50-150 |

Coarse powder for feeding stability, high flowability |

Inconel 718, Titanium Alloys |

Stanford Advanced Materials (SAM) offers a variety of spherical alloy powders with different particle size ranges, suitable for applications in SLM, DMLS, EBM, Binder Jetting, DED, LMD, and thermal spraying processes.

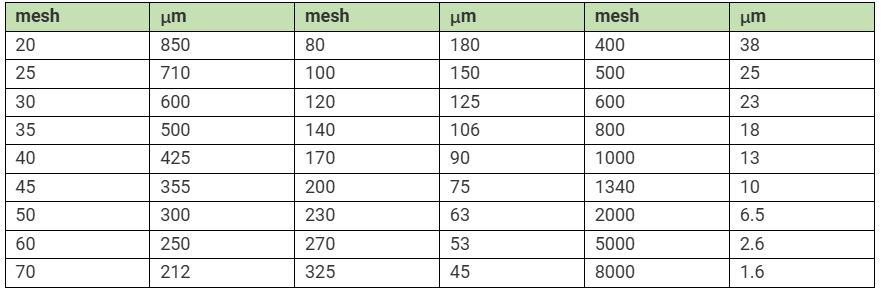

Mesh vs. Micron Conversion

Besides microns (μm), mesh is another common unit for particle size. Mesh indicates the number of openings per linear inch in a sieve—higher mesh numbers mean smaller openings. Note that standards vary by country, so mesh-to-micron conversions may differ.

Below is a general mesh-to-micron conversion table for reference:

1. Why is particle size important in 3D printing of metals?

Particle size affects powder flowability, layer uniformity, print accuracy, and final part density. Each process (SLM, EBM, DED) requires optimized size ranges for best results.

2. What is the typical particle size range for SLM/DMLS printing?

Most SLM/DMLS processes utilize powders between 15 and 63 µm, with 20 to 53 µm being ideal for high resolution and smooth surfaces.

3. Why does EBM use coarser powders than SLM?

EBM (Electron Beam Melting) requires 45–106µm powders for better flowability under high-energy electron beams and preheating conditions.

4. Can binder jetting use wider particle size distributions?

Yes, binder jetting uses 10–100µm powders since it prefers sintering density to ultra-fine layer uniformity.

5. What is the optimum particle size for DED/LMD processes?

DED (Directed Energy Deposition) typically uses 50–150µm powders for reliable powder feeding and to prevent nozzle blockage.

6. What is the effect of particle size on part density in 3D printing?

The smaller powders are advantageous to density and surface finish, while the larger powders are advantageous to build rate and flowability.

7. Why is D50 utilized as the average particle size?

D50 divides the powder into equal parts—50% finer and 50% coarser—which gives a reproducible midpoint reference.

United States

.png)