The introduction of high-entropy alloy powders has revolutionized traditional notions in alloy design. Traditional alloys have 1-2 principal elements with minor additions to enhance performance. For example, widely used high-temperature nickel C103 alloy depends on niobium and hafnium with minor additions of titanium and zirconium. In contrast, high-entropy alloy powders consist of five or more principal elements without a single dominant component.

Research shows that high-entropy alloys possess numerous superior properties compared to traditional alloys, owing to their multi-principal-element compositional design. This "decentralized" alloy strategy leverages extremely high mixing entropy to suppress the formation of intermetallic compounds, favoring simple solid-solution structures (BCC, FCC, or HCP). This design philosophy gives rise to four core effects in HEAs:

When n ≥5, mixing entropy is more than 15 times in normal alloys, effectively inhibiting phase separation. It renders HEAs stable at elevated temperatures in microstructure. For instance, the AlCoCrFeNi alloy possesses mixing entropy of 1.61R and does not precipitate at 1000°C.

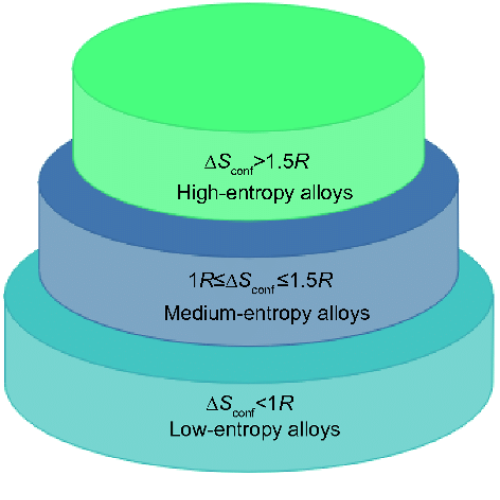

Fig 1. Alloys world based on the configurational entropy.[1]

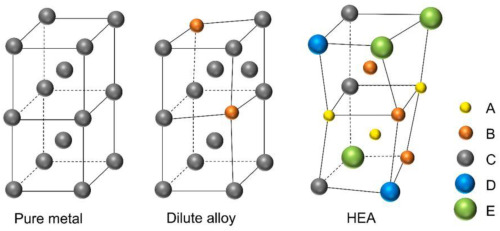

Atomic size differences among some elements bring about lattice distortion, which bestows ultrahigh strength and resistivity on materials. An example is that the AlCoCrFeNi alloy achieves three times the hardness of 316L stainless steel.

Fig 2. Schematic representation of lattice distortion in BCC pure metals, conventional dilute alloys, and HEAs.[2]

Synergistic interactions among multiple elements increase atomic diffusion activation energy by 30%-50%, thereby enhancing high-temperature stability significantly. No apparent changes are found for CoCrFeNi after 1000-hour aging at 800°C.

Multi-principal-element synergy produces a "1+1>2" enhancement higher than the performance of the constituent components. FeCoCrNiAl alloy attains 18% elongation and 1.2 GPa tensile strength, transcending the traditional strength-ductility trade-off issue.

Atomization is one of the most commonly used methods. Among these, gas atomization is the break-up of the molten high-entropy alloy stream into fine droplets by high-pressure inert gas and high-rate solidification. The process can produce powders of high sphericity with good flowability, which are particularly versatile for use in industries such as 3D printing. Another atomization technique is plasma rotating electrode process (PREP). It utilizes centrifugal force from a rotating electrode to eject molten metal, forming powders that are especially suitable for high-melting-point and reactive metals, while achieving extremely high powder purity.

Mechanical alloying is a solid-state synthesis method. It achieves atomic level homogenization by high-energy ball milling of elemental metal powders over long periods of time. The process can produce nanocrystalline or amorphous high-entropy alloy powders.

The above processes are physical methods, and high-entropy alloy powders can also be synthesized by chemical means. Co-reduction and sol-gel are the most commonly used ones. Co-reduction directly generates alloy powders by chemical reduction of metal salt solutions. The sol-gel process, however, first forms oxide precursors, which are then reduced to form alloy powders. Powders resulting from these kinds of processes can be as small as nanoscale and thus are particularly favored for use as catalysts or coatings.

Table 1. Summary of characteristics of different preparation processes

|

Method |

Particle Size Range |

Morphology |

Purity |

|

Gas Atomization |

15-150 μm |

Spherical |

High |

|

Mechanical Alloying |

0.1-10 μm |

Irregular |

Medium |

|

Co-reduction |

10-500 nm |

Porous |

Medium |

|

PREP |

50-200 μm |

Spherical |

Ultra-high |

Read more: The 12 Most Exceptional High-Entropy Alloy Powders

HEA powders are driving technological breakthroughs in extreme environments across multiple industries.

NiCoCrAlY HEA coating significantly enhances high-temperature life for critical aero-engine parts. Test results show that this coating raises the operation temperature limit of turbine blades by 200°C. NASA has adopted this material system for next-generation engine hot-section components, such as those in the GE9X.

The Ti-Zr-Nb-Ta-Mo HEA system is extremely biocompatible. ISO 10993 certification confirms its elastic modulus (93±5 GPa) is similar to human bone tissue, and its antibacterial rate is 99.9%. It is approved by the FDA and is now being used in personalized 3D-printed bone implants. Compared with traditional titanium alloys, the stress shielding and infection risk are reduced.

The FeCoNiCuPd HEA nanocatalyst achieves water electrolysis for hydrogen production milestones. The 1M KOH test achieves a 32 mV overpotential for hydrogen evolution at 10 mA/cm², 36% lower than commercial Pt/C (~50 mV), and 40% greater energy conversion efficiency. The innovation offers new solutions for scalable clean hydrogen production.

Stamford Advanced Materials (SAM) is committed to providing high quality spherical alloy powders to customers in the industrial sector. We offer a wide range of HEA spherical powders to meet the needs of a variety of additive manufacturing, aerospace and other diverse processes.

[1] Zhang, Wei & Zhang, Yong. (2018). Science and technology in high-entropy alloys. Science China Earth Science. 2-22.

[2] Tushar Sonar, Mikhail Ivanov, A comprehensive review on fusion welding of high entropy alloys – Processing, microstructural evolution and mechanical properties of joints, International Journal of Lightweight Materials and Manufacture, Volume 7, Issue 1, 2024, Pages 122-183, ISSN 2588-8404, https://doi.org/10.1016/j.ijlmm.2023.06.003.

United States

.png)